Light material separation device

A separation device and material technology, applied in the direction of solid separation, separation of solids from solids with airflow, recycling of construction waste, etc., can solve the problems of high labor costs, inability to separate accurately, time-consuming and labor-consuming, etc., to reduce dust Pollution and noise pollution, avoid scattering, improve the effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

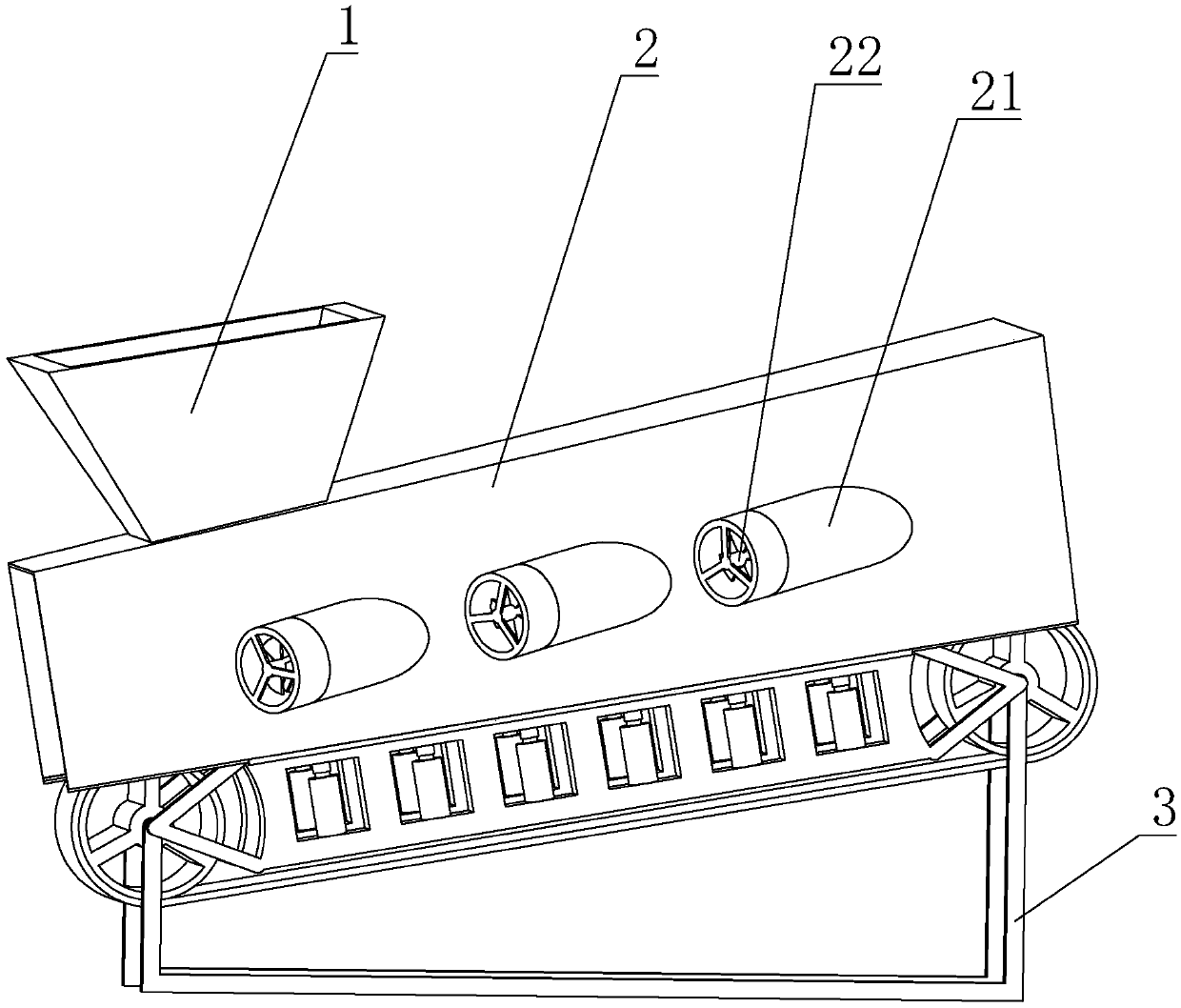

[0038] Embodiment one, see Figure 1-4 , this embodiment discloses a light material separation device, including an air supply mechanism and a material throwing mechanism, the air supply mechanism includes a sealing cover 2 buckled above the material throwing mechanism, and an air inlet arranged on the sealing cover 2 The duct 21 and the air inlet duct 21 are symmetrically welded on both sides of the sealing cover 2, and form an angle of 45 degrees with the sealing cover 2. The air inlet duct 21 is symmetrically arranged on both sides of the sealing cover 2. Blow the material from the side at the same time, so that the material is more evenly exposed to the wind. The air inlet pipe 21 is arranged obliquely on the sealing cover 2, so that the material not only receives an upward force but also a forward force when it is exposed to the wind, which is beneficial to the material. Sorting and transportation, improve sorting and conveying efficiency; The air inlet duct 21 is multipl...

Embodiment 2

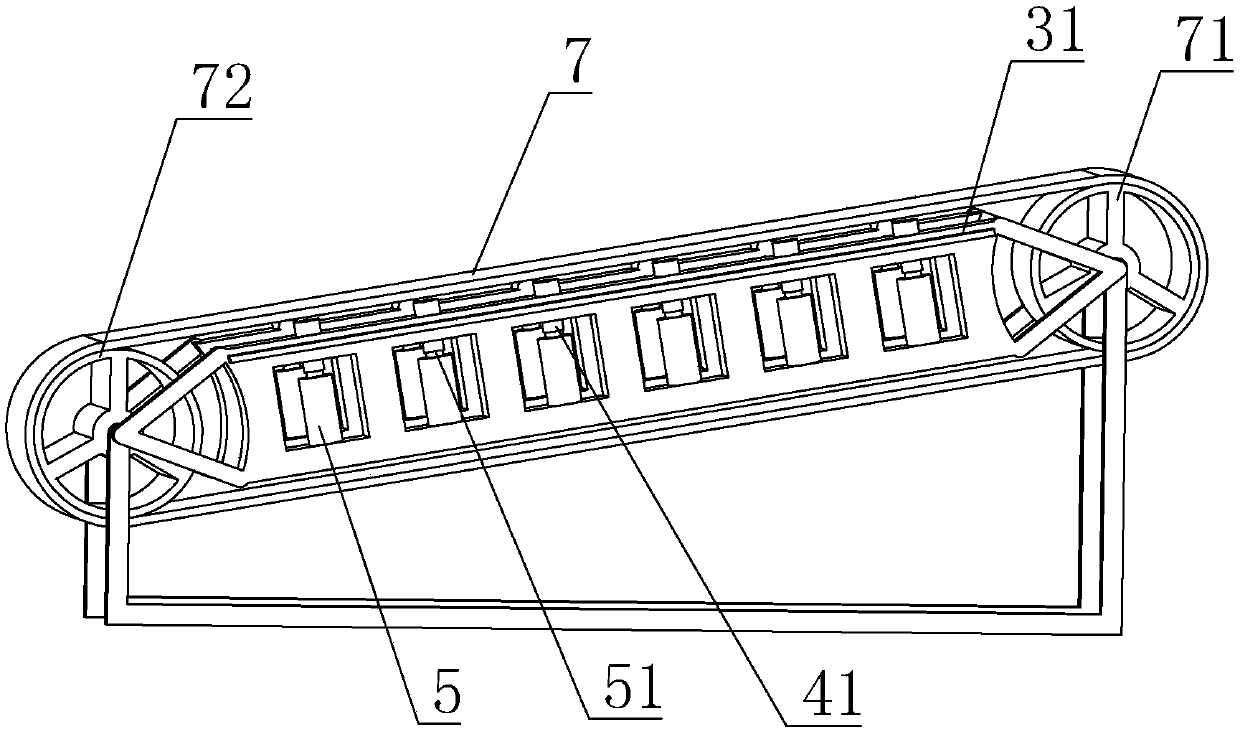

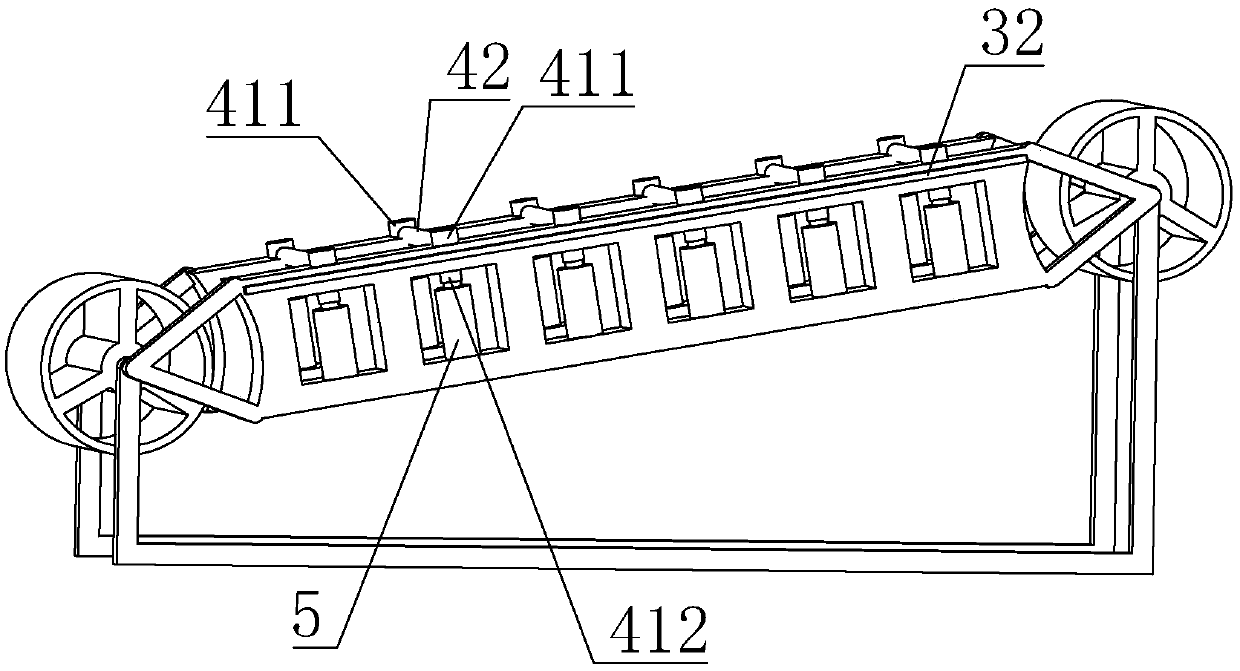

[0041] Embodiment two, see Figure 5-10 , this embodiment discloses a light material separation device, including an air supply mechanism and a material throwing mechanism, the air supply mechanism includes a sealing cover 2 buckled above the material throwing mechanism, and an air inlet arranged on the sealing cover 2 The duct 21 and the air inlet duct 21 are symmetrically welded on both sides of the sealing cover 2, and form an angle of 45 degrees with the sealing cover 2. The air inlet duct 21 is symmetrically arranged on both sides of the sealing cover 2. Blow the material from the side at the same time, so that the material is more evenly exposed to the wind. The air inlet pipe 21 is arranged obliquely on the sealing cover 2, so that the material not only receives an upward force but also a forward force when it is exposed to the wind, which is beneficial to the material. Sorting and transportation, improve sorting and conveying efficiency; In the present embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com