Ferrite area endless rolling method of extremely thin strip steel

A technology of endless rolling and ferrite, which is applied in metal rolling and other directions, can solve the problems of high power and prominent energy consumption, and achieve the effects of preventing large temperature drops, reducing production accidents, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and beneficial effects of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

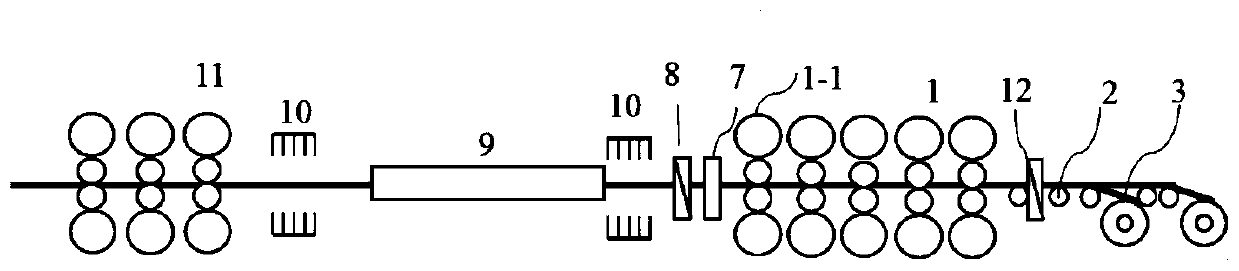

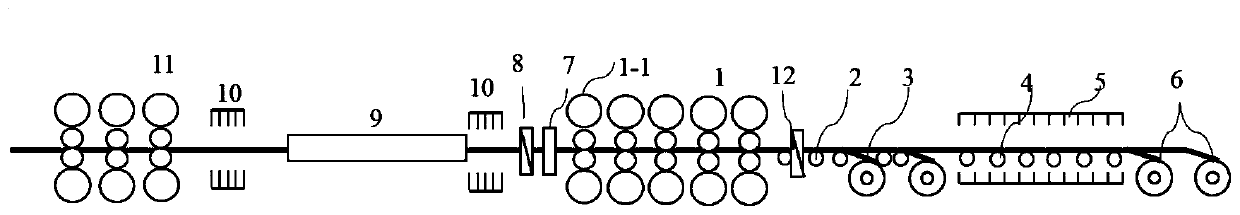

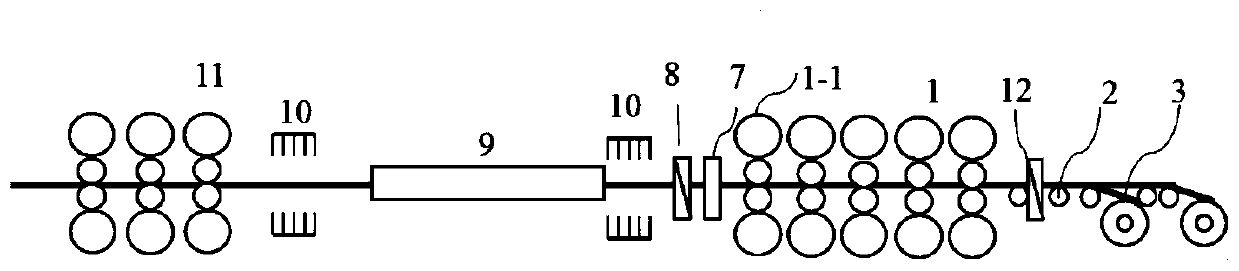

[0034]A ferrite region endless rolling method of ultra-thin strip steel comprises: hot rolling strip steel continuous casting and hot rolling production line, the thickness of slab after endless continuous casting is 70-150mm. The production line includes initial descaling (not listed in the figure), roughing mill 11, induction heating device 9 (not necessarily used when rolling extremely thin strip steel in the ferrite zone), intermediate billet cooling 10, cutting shears 8, and fine descaling 7. Rolling in the ferrite area is realized in the finishing rolling unit 1, the short-distance conveying roller table 2 and the short-distance coiler 1. When the ultra-thin specification strip steel is rolled in the ferrite zone, one end of the short-distance conveyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com