A fixing fixture for welding of heating and ventilation pipes

A fixing fixture and HVAC technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficult positioning of HVAC pipes, affecting the sealing of HVAC pipes, and unstable fixing of HVAC pipes, etc. , to achieve the effect of fast fixed clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

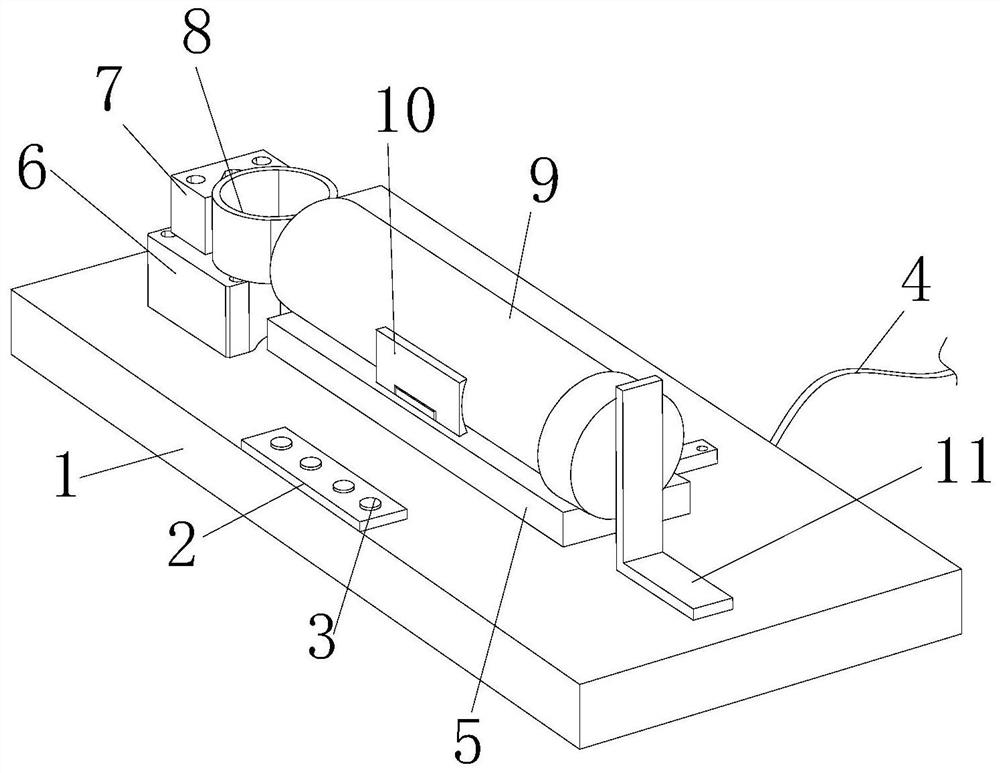

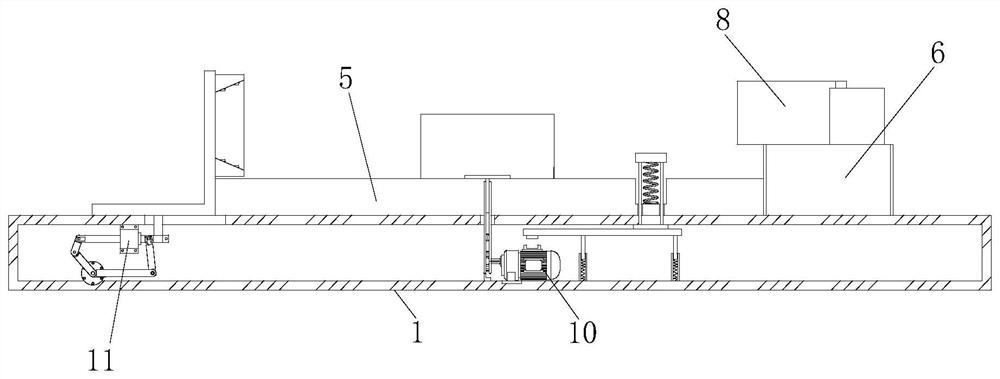

[0034] see figure 1 and figure 2 , the present invention provides a fixing fixture for heating and ventilation pipe welding through improvement, including a bottom plate 1, a heating and ventilation pipe 9, a clamping and fixing device 10 and a positioning and pushing device 11. A control panel 2 is provided at the top and front end of the bottom plate 1, The top of the control panel 2 is equipped with a button 3, the clamping and fixing device 10 is fixedly installed in the middle of the interior of the bottom plate 1, the positioning and pushing device 11 is fixed to the left end of the interior of the bottom plate 1, the rear end of the bottom plate 1 is provided with a power lead 4, the bottom plate 1 and the support plate 5 The bottom is fixed, the bottom plate 1 is bolted to the bottom of the first fixed plate 6, the bottom of the first fixed plate 6 and the second fixed plate 7 are fixed as one, the second fixed plate 7 is fixed to the left end of the top ring 8 by ele...

Embodiment 2

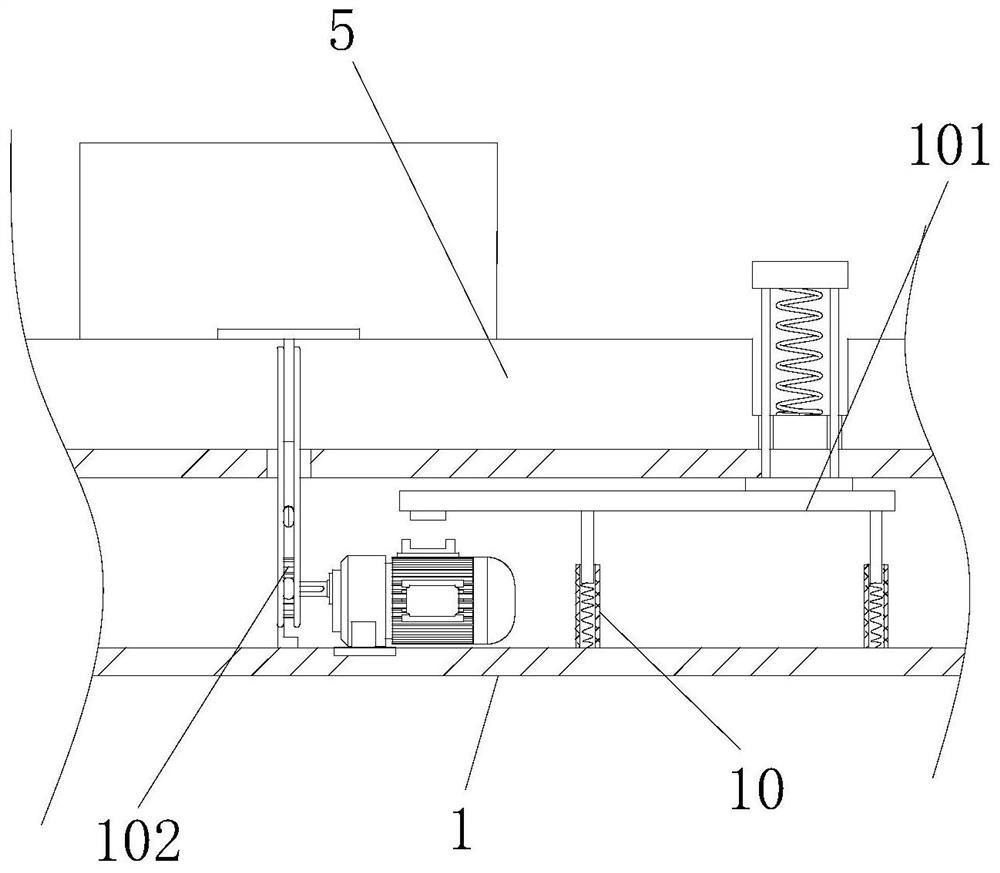

[0042] The present invention provides a fixing fixture for heating pipe welding through improvement. The lead block 1019 is located at the upper end of the lead block 10110, and the lead block 10110 is fixedly connected to the upper end of the first motor 10111, which is beneficial to the first motor 10111. A motor 10111 is powered on, and the rotating gear 1022 is connected to the output end of the first motor 10111 in rotation, which is conducive to making the rotating gear 1022 rotate smoothly. The shaft 1016 moves smoothly. One end of the second movable rod 1116 rotates synchronously with the output end of the second motor 1111. The cross section of the slot 1123 is in the shape of an isosceles trapezoid. There are two sliding shafts 1016, and the sliding shafts 1016 are respectively located on the The right side of the lower end of the horizontal plate 1015, the lower left end of the horizontal plate 1015, and the lower ends of the two sliding shafts 1016 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com