Construction method for basement cast-in-situ outer wall seepage prevention

A construction method and basement technology, applied in the treatment of walls, building materials, building components, etc., can solve the problems of unstable air bubbles, limited durability, large drying shrinkage, etc., achieve good anti-seepage effect, ensure anti-seepage effect, The effect of increasing the laying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below with reference to the drawings and embodiments.

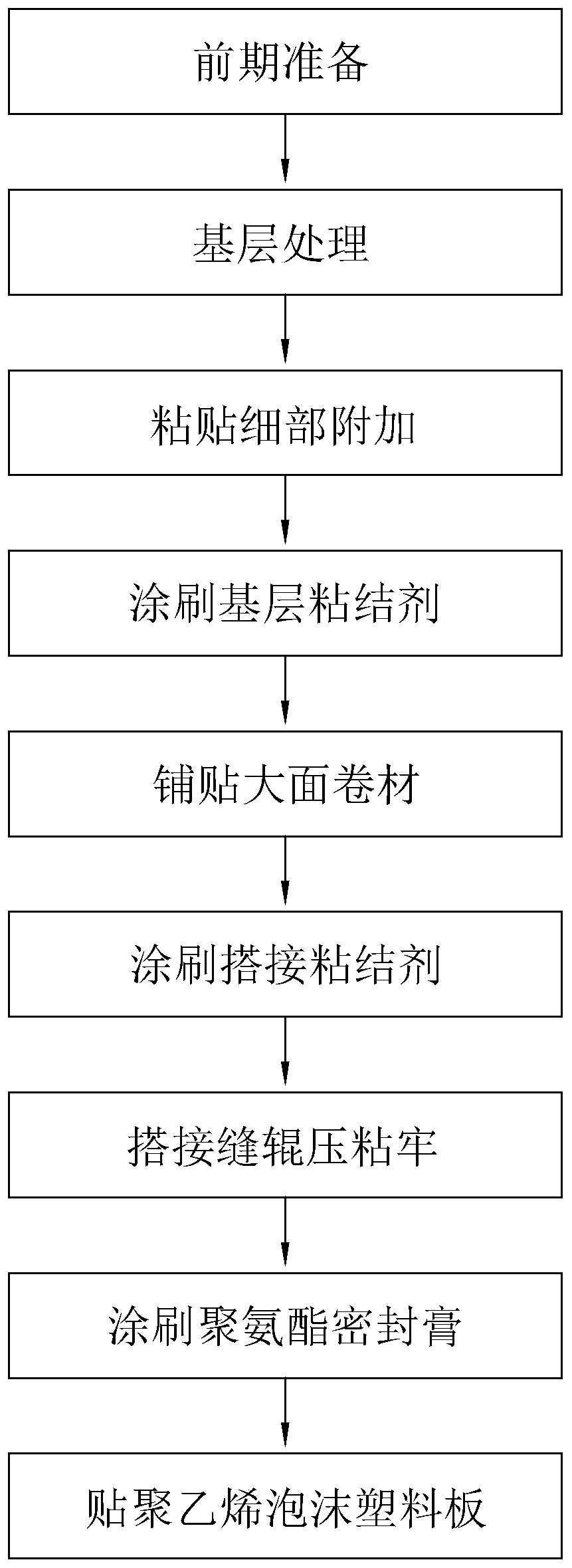

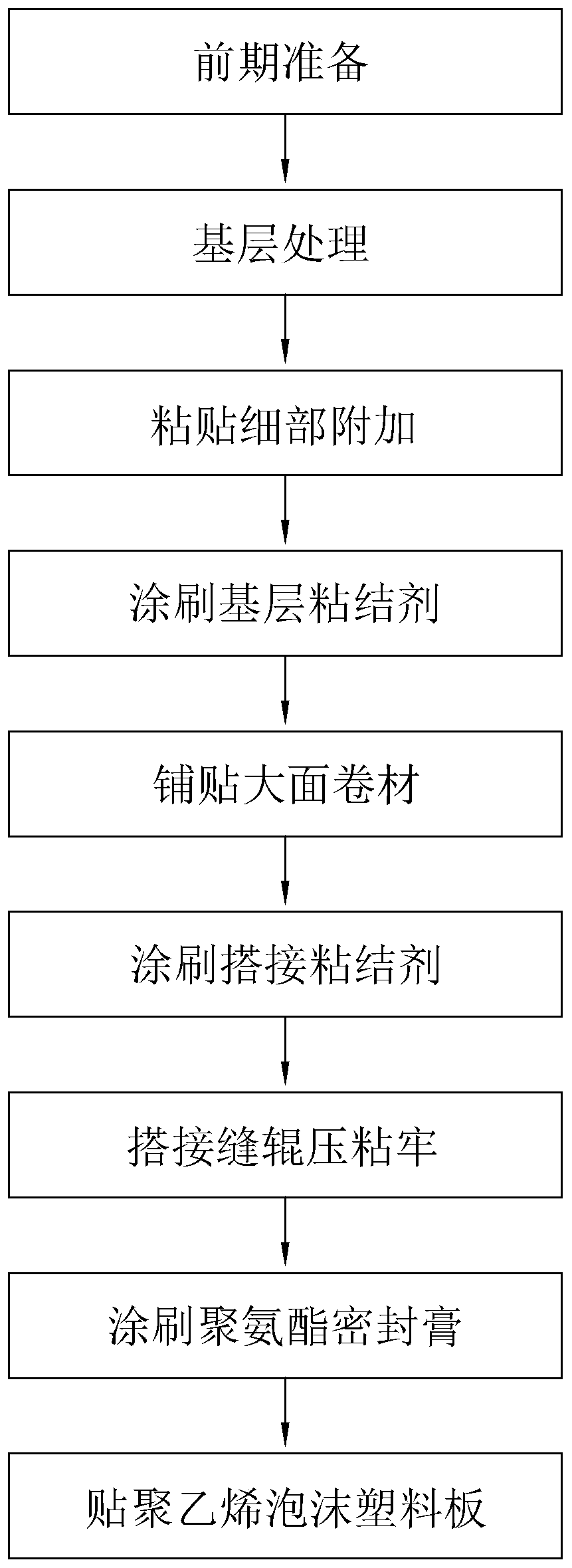

[0041] The invention provides a construction method for seepage prevention of cast-in-place exterior walls in basements, with reference to figure 1 , Including the following steps:

[0042] S1: First pick up the skids, then cut the wall bolts along the root of the skid holes, and plug them with cement mortar. The cement mortar can block the leaking points, leaking lines and leaking seams at the wall bolts.

[0043] S2: Arrange the dimensions on the surface of the base layer, and pop up the marking line as a reference line for laying the coil. This process can facilitate the worker to lay the coil quickly and accurately in the subsequent steps.

[0044] S301: Thoroughly remove rust, grease, dust, etc. on the surface of the wall, polish it smoothly, and apply glue evenly after the base layer is dry:

[0045] S302: In step S301, the polyurethane should be evenly coated on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com