Auxiliary transformer cabinet draught fan

A technology for auxiliary transformers and fans, which is applied in the direction of machines/engines, electromechanical devices, mechanical equipment, etc. It can solve the problems of internal flow field disorder of auxiliary transformer cabinet fans, deviation from rated operating point, and inability to be lifted, etc., to achieve a simplified structure, Unobstructed air flow and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

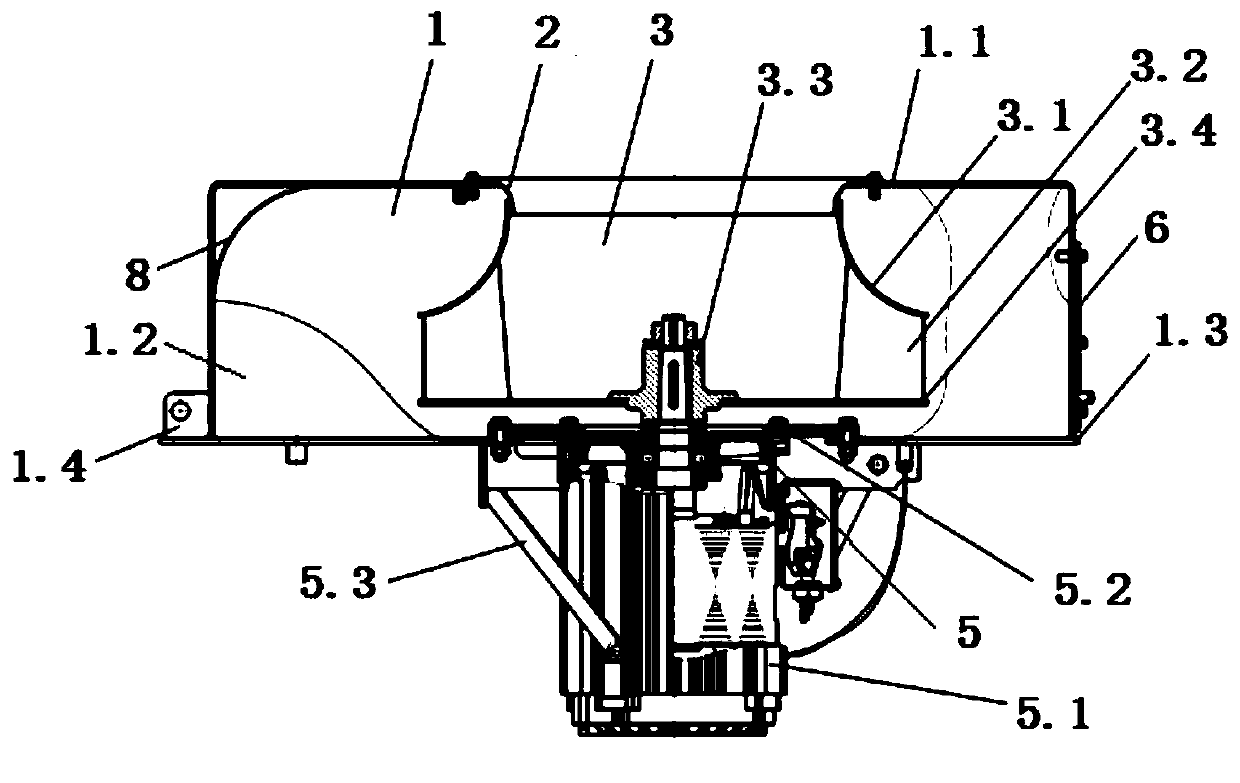

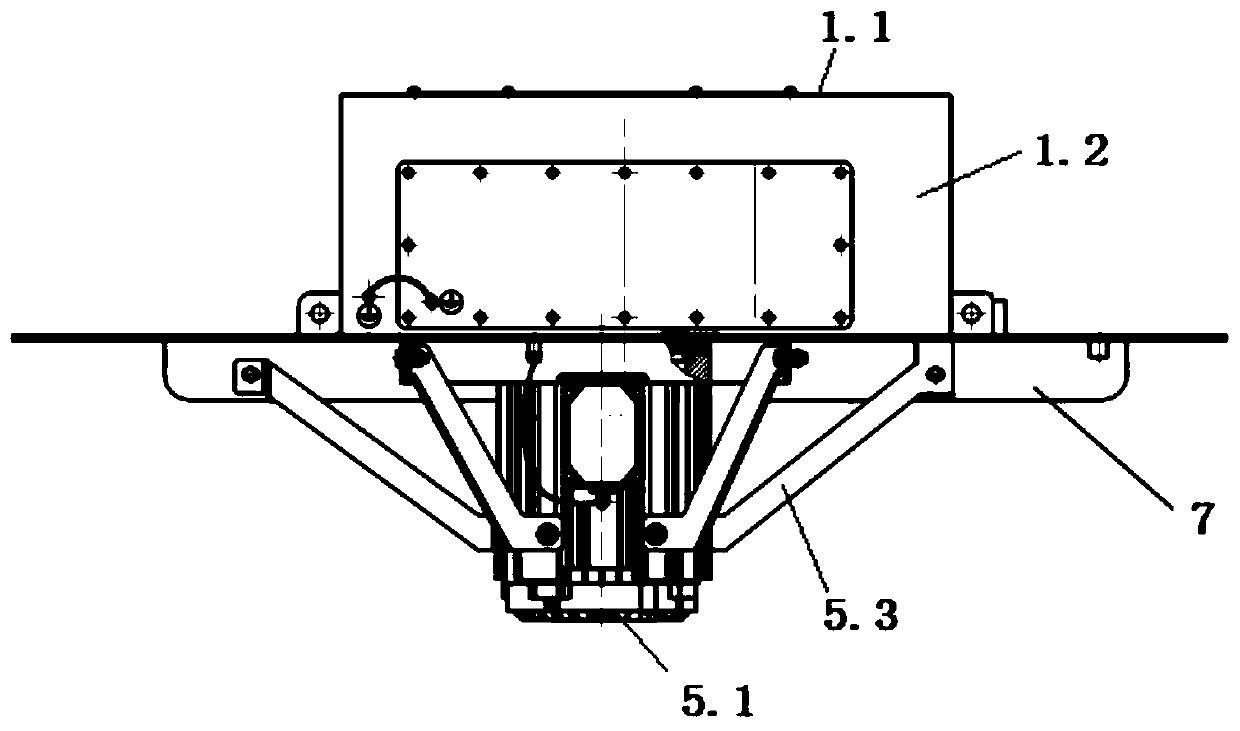

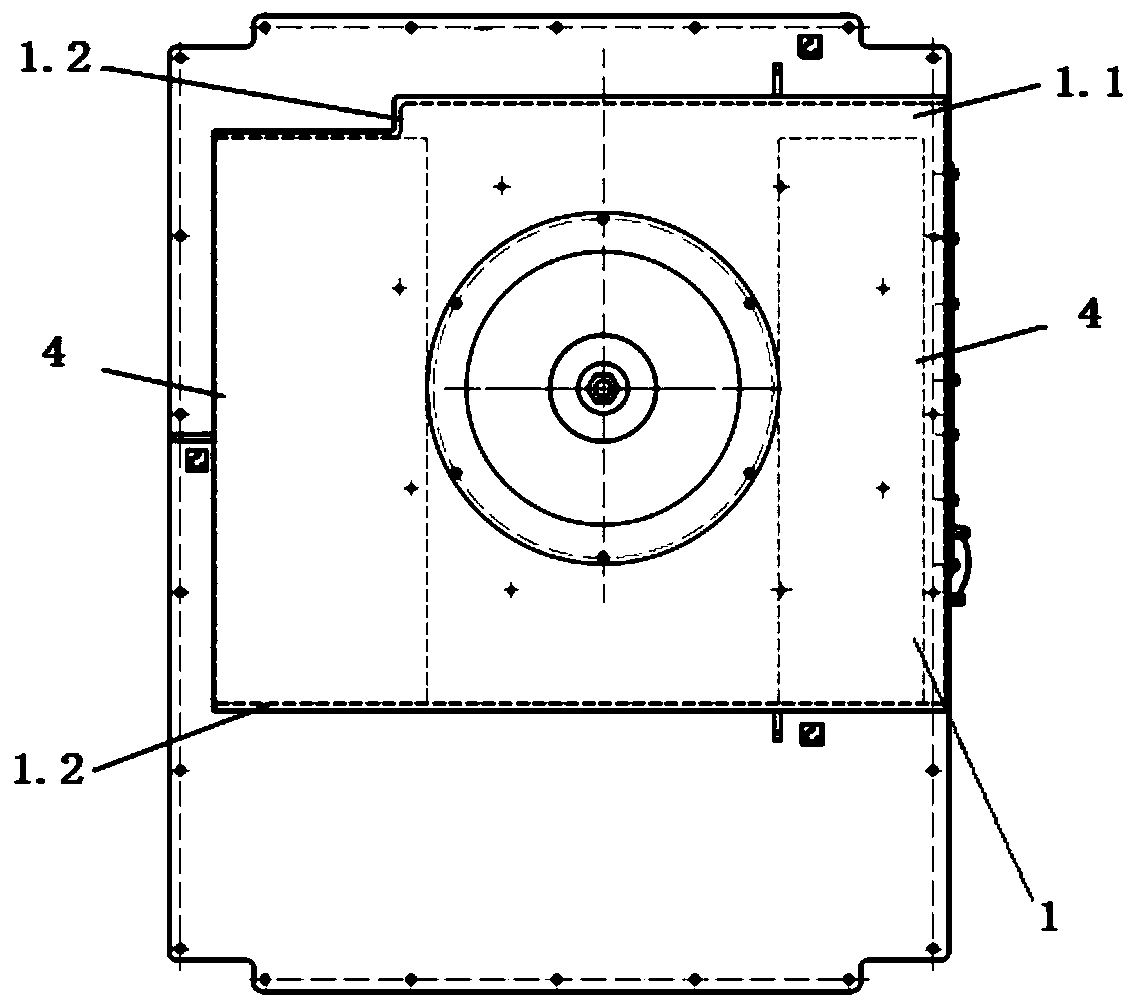

[0035] An auxiliary transformer cabinet fan, see Figure 1-3 , including casing assembly 1, air inlet 2, impeller 3, air outlet 4 and power source 5, the detailed structure is as follows:

[0036] The casing assembly 1 is a box-shaped casing structure formed by a casing cover plate 1.1, a casing side plate 1.2, and a casing bottom plate 1.3, and also includes lifting lugs 1.4, grounding blocks and other components. The box-shaped structure of the volute. The casing cover 1.1 is provided with an installation opening for installing the air inlet 2, the installation opening is opened in the middle of the casing cover 1.1, and the installation opening is a circular opening, and the periphery of the circular opening is A plurality of rivet nuts are uniformly arranged for fixing the air inlet 2 . The casing bottom plate 1.3 is provided with at least two air outlets 4, preferably two air outlets 4 with different specifications located at the left and right ends of the casing bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Exit width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com