Integrated mirror surface processing assembly-free optical telescope and processing method thereof

A mirror surface processing, integral technology, applied in the direction of telescopes, optics, optical components, etc., can solve the problems of structural adjustment and optical assembly and calibration, the impact of imaging quality installation stress, and small temperature adaptation range, etc., to achieve simple structure and reliability High performance and wide range of temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Provide a preferred embodiment of the present invention below in conjunction with accompanying drawing, mainly describe in further detail the characteristics of the present invention, but not be used for limiting the scope of the present invention:

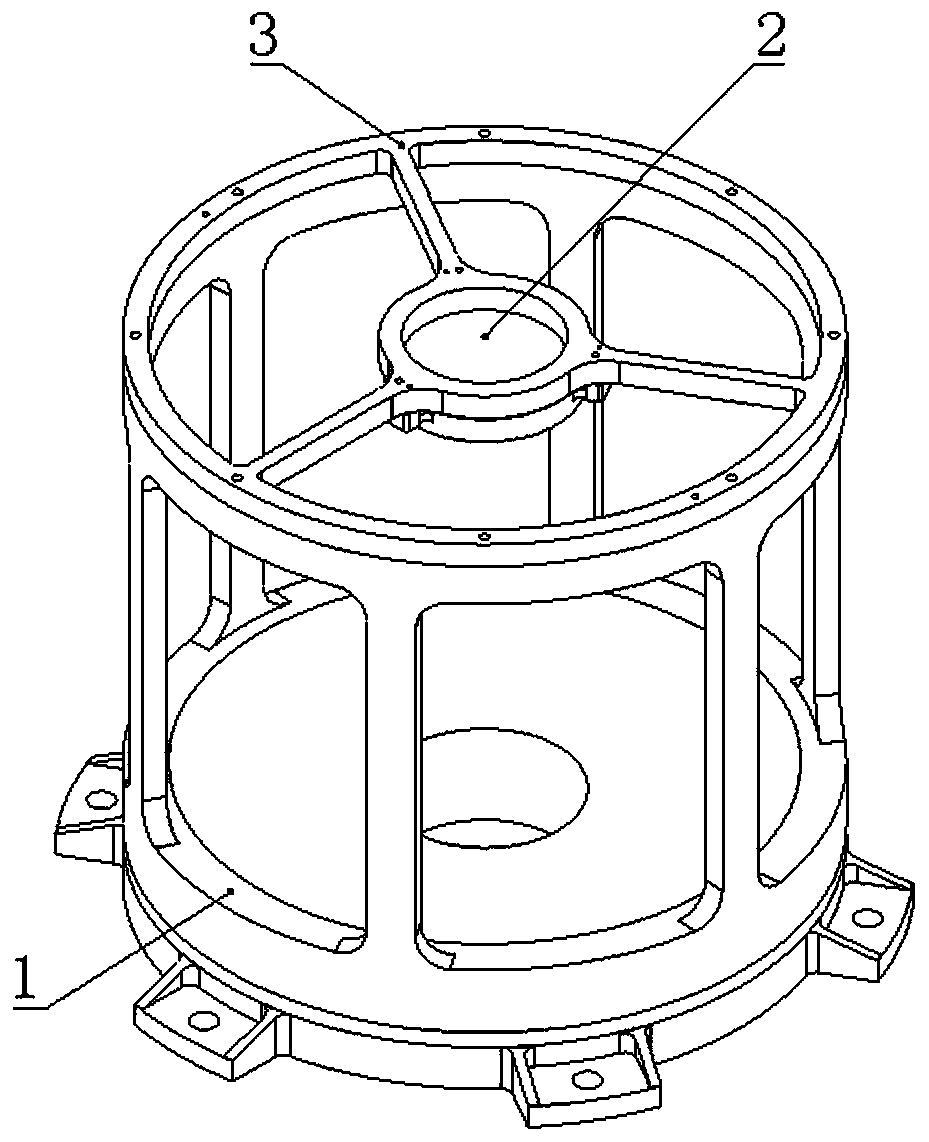

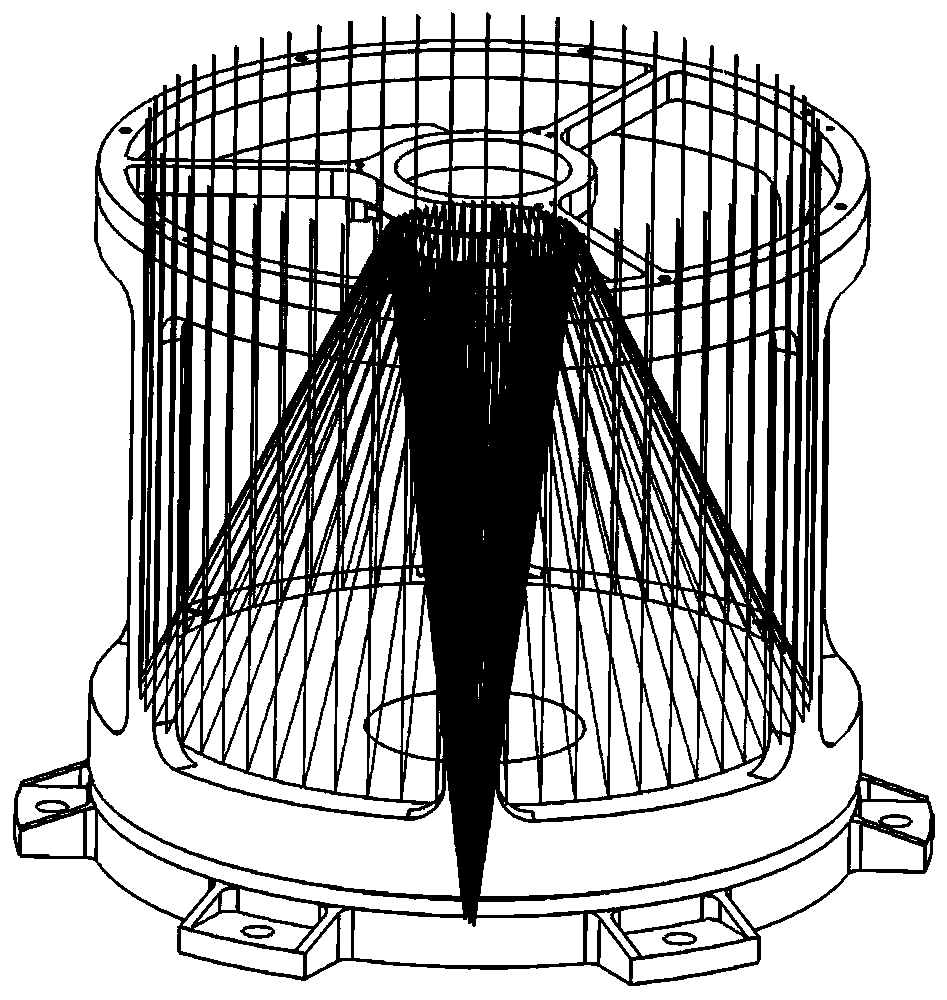

[0028] see figure 1 with figure 2 , the integral mirror processing free calibration optical telescope, including integral primary mirror reflector 1, secondary mirror reflector 2, secondary mirror mounting frame 3; it is characterized in that:

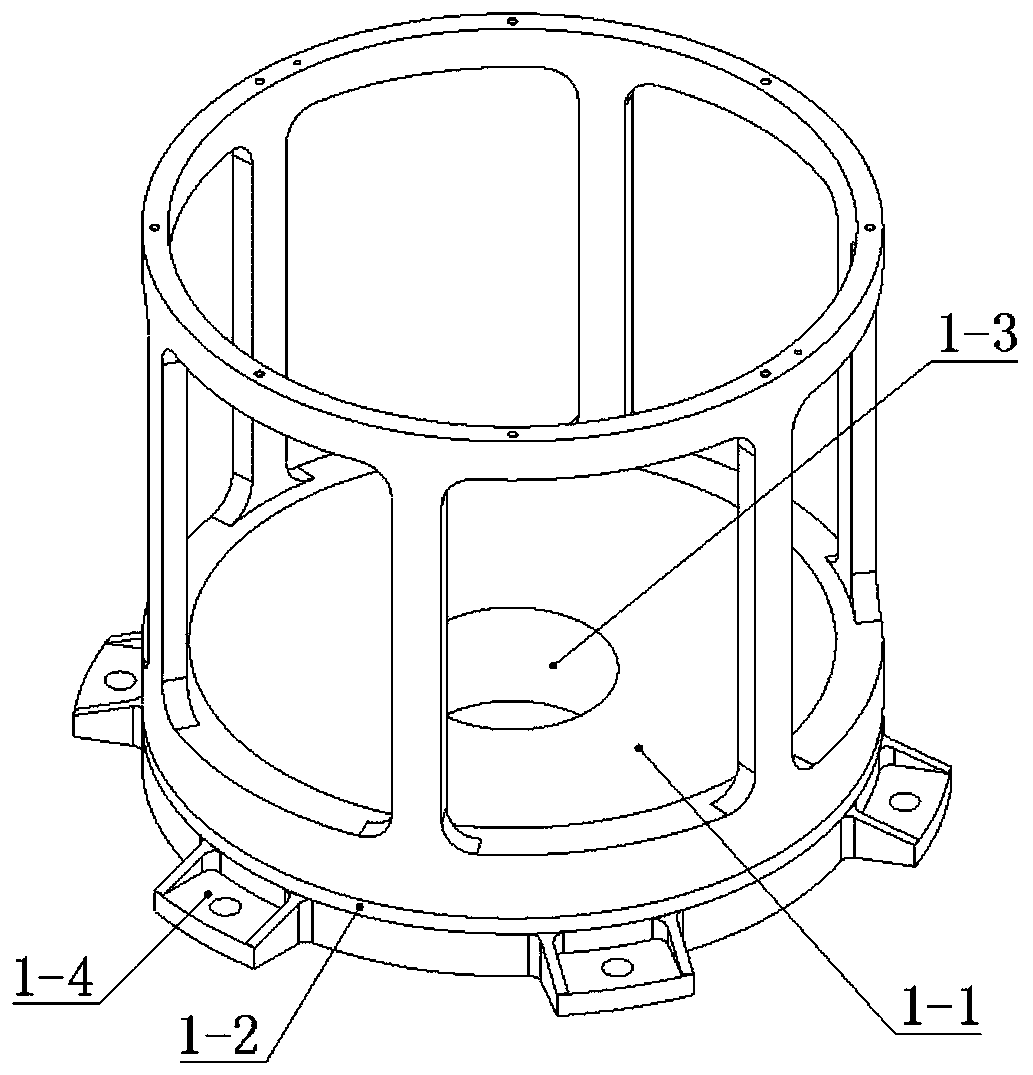

[0029] see image 3 with Figure 4 , the material of the integral primary mirror reflector 1 is grade 7075 aluminum alloy, the upper part of the integral primary mirror reflector 1 is a ring structure, the lower part is a cylindrical structure, and the middle part is a structure of six supporting ribs; the lower part of the integral primary mirror reflector 1 is a cylindrical structure A concave optical mirror surface 1-1 is processed on the upper surface, and a ring-shaped flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com