A Multifunctional Supervision System Oriented to Stamping Workshop

A supervision system and stamping workshop technology, applied in the field of multi-functional supervision system, can solve the problems of workshop production optimization and evaluation, time waste, production cost increase, etc., to achieve the effect of improving workshop production efficiency, reducing production cost, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In this embodiment, the stamping workshop is a typical discrete manufacturing workshop and the basic production workshop of the machinery manufacturing industry. Because its production characteristics are obviously different from the traditional assembly workshop, it needs targeted analysis and design.

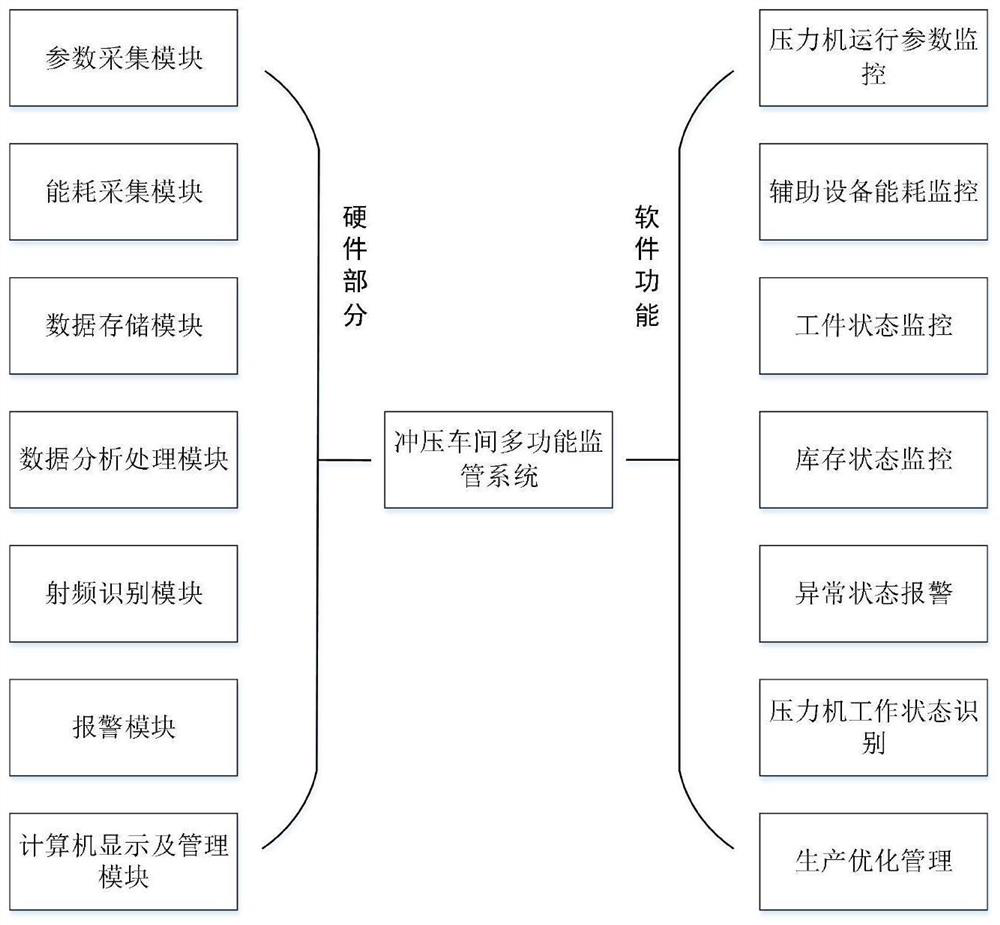

[0041] figure 1 It is a schematic diagram of the hardware and software structure of the present invention, specifically, a multi-functional supervision system for stamping workshops, including the following functions: 1. Monitoring of press machine operating parameters, 2. Monitoring of energy consumption of auxiliary equipment, 3. Monitoring of workpiece status, 4. Inventory status monitoring, 5. Abnormal status alarm, 6. Press working status identification, 7. Production optimization management. Its hardware includes: 1. Parameter acquisition module, 2. Energy consumption acquisition module, 3. Data storage module, 4. Data analysis and processing module, 5. Radio freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com