Lightweight honeycomb type low-frequency sound insulation metamaterial structure

A metamaterial, honeycomb-type technology, applied in the direction of sound-generating devices, chemical instruments and methods, instruments, etc., to achieve the effects of reducing the overall quality, satisfying the sound insulation bandwidth, and excellent geometric mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

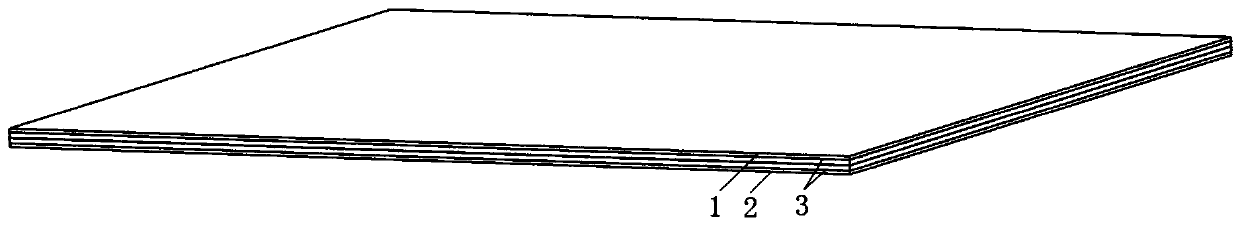

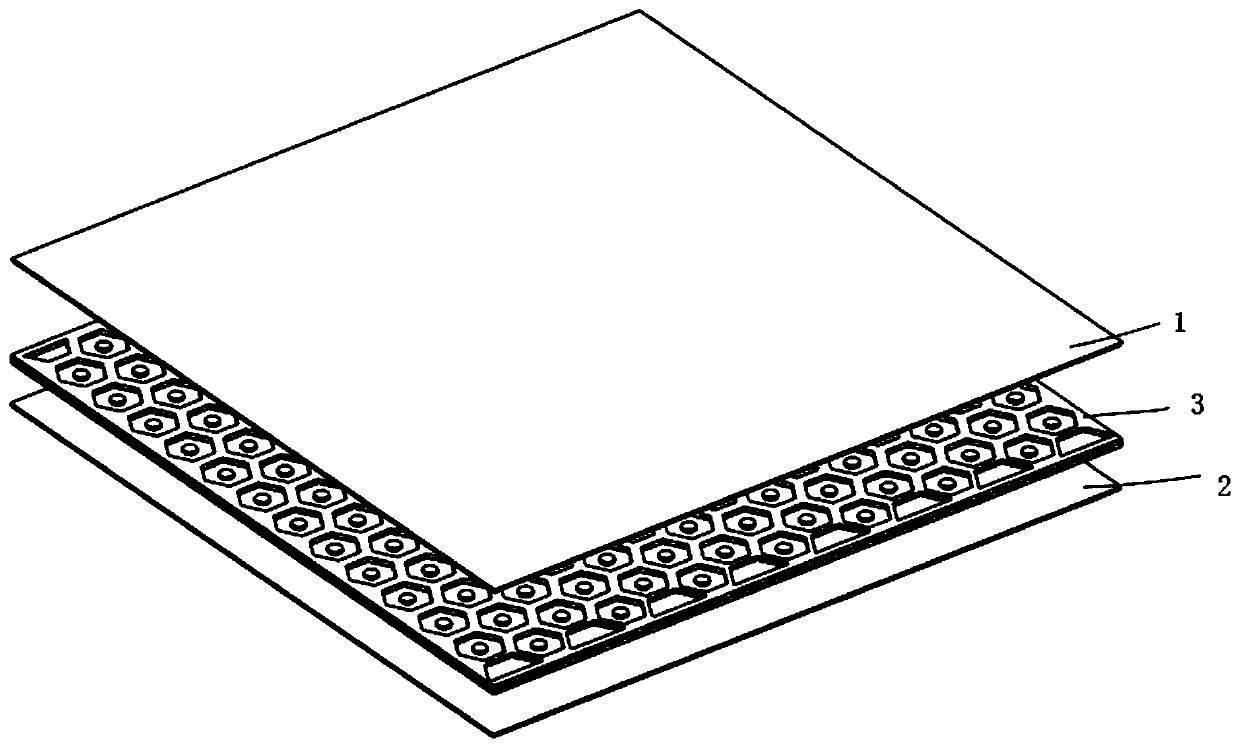

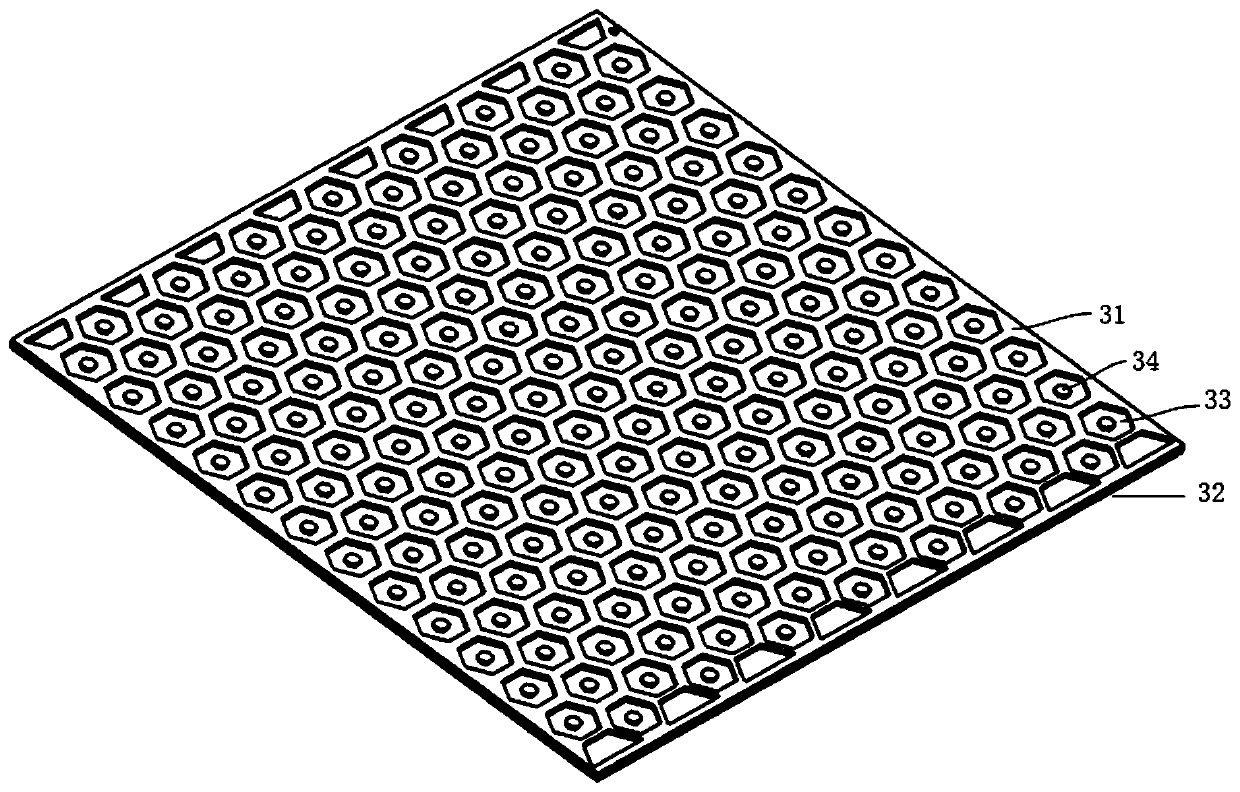

[0039] figure 1 It shows a structural schematic diagram of a lightweight honeycomb low-frequency sound-insulating metamaterial according to an embodiment of the present invention, figure 2 An exploded view of a lightweight honeycomb low-frequency sound-insulating metamaterial structure of this embodiment is shown, which includes two upper and lower layers covering the upper homogeneous sheet layer 1 of the metamaterial and the lower homogeneous sheet layer 2 of the metamaterial, and Honeycomb metamaterial layer 3 wrapped in the middle. image 3 Shows a schematic structural view of the honeycomb metamaterial layer 3 in the middle, including a two-layer frame (upper frame 31 and lower frame 32), an elastic film 33 in the middle of the two-layer frame, and an additional quality block 34 on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com