Grid slitting device and slitting method

A grid and continuous plate technology, applied in the field of lead-acid battery grid production equipment, can solve the problems of large spacing, large diameters of traction rollers and cutter rollers, and small frame size of unit grids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

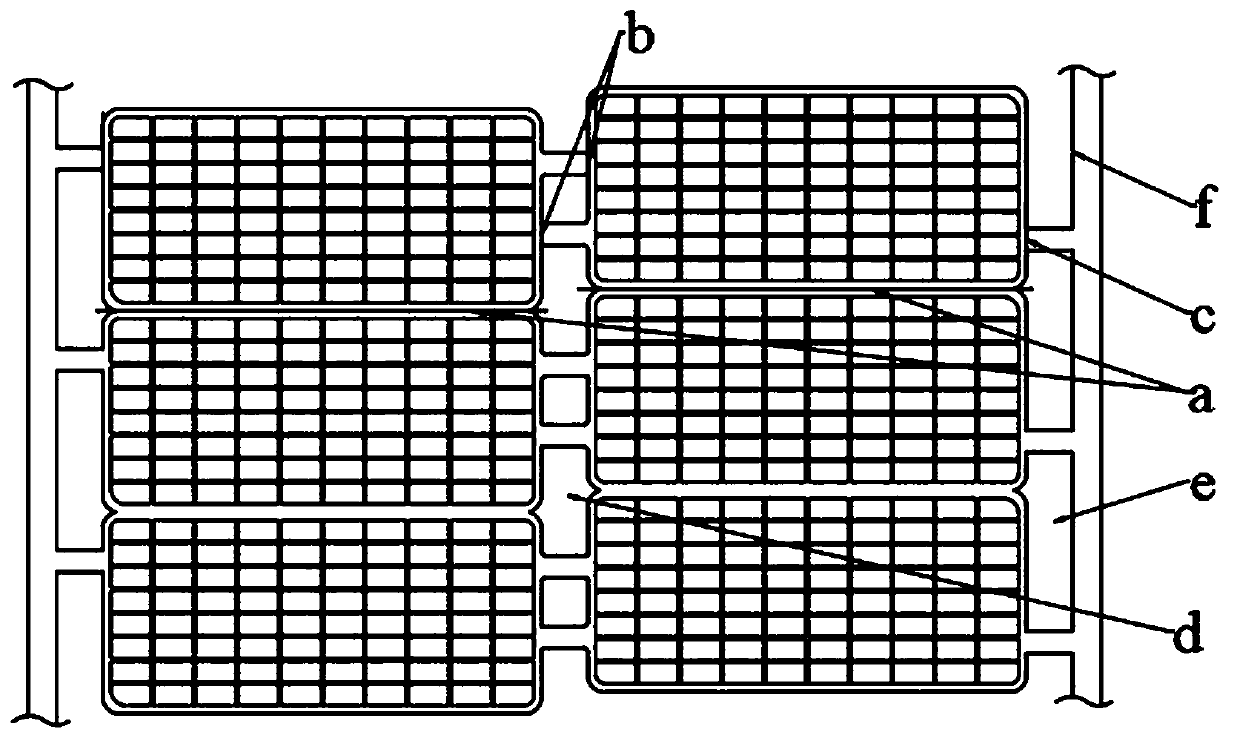

[0045] The continuous grid cut by the grid slicing device is as follows: figure 1As shown, the continuous grid is integrally connected by unit grids, the unit grids are distributed in two rows, the tabs of the grid are located between the grid frames of the two rows, and the two sides of the continuous grid are integrally connected with process connection strips f, cut along the tangent line a between the frame, the tangent line b of the tab and the tangent line c of the grid connecting strip (a is the tangent line in the width direction, b and c are the tangent lines in the extending direction of the continuous grid), and you can get Uniformly shaped cell grids. The first positioning hole d is formed by the grid and the pole lug, and the second positioning hole e is formed by the process connecting strip and the same row of grids. The distribution of unit grids in continuous grids and the orientation of tabs can be adjusted based on actual needs.

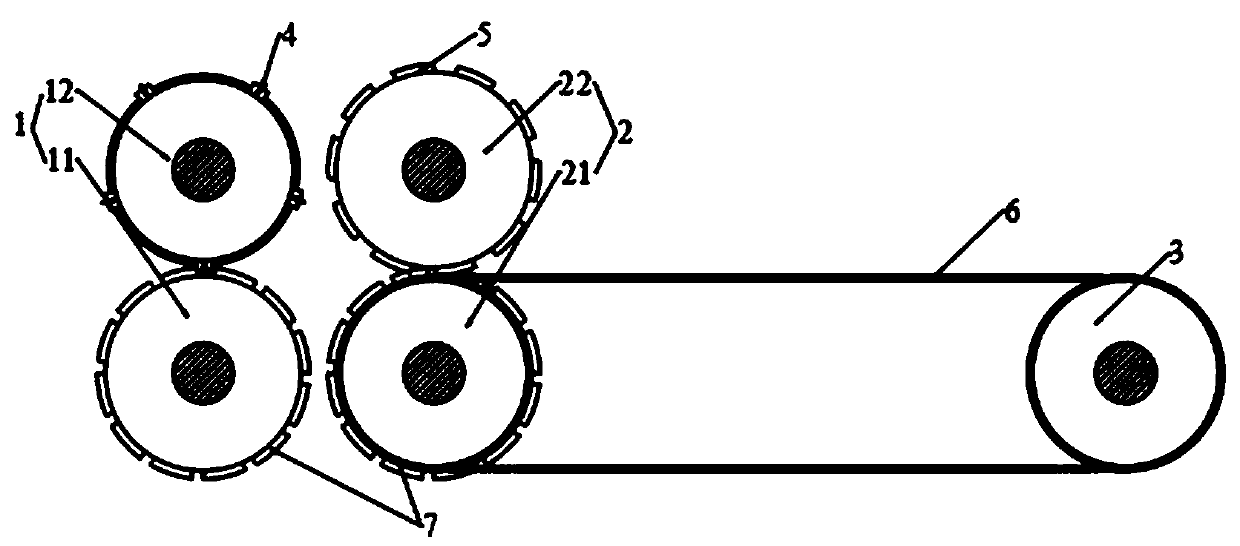

[0046] Such as Figure 2...

Embodiment 2

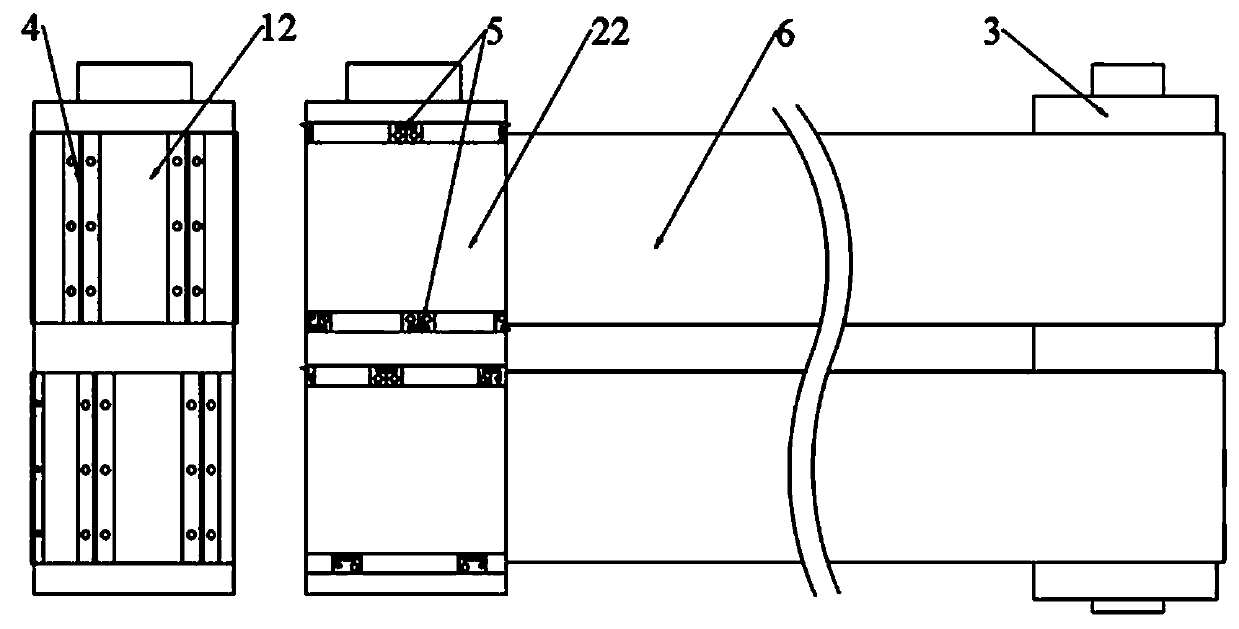

[0053] Such as Figure 7-8 As mentioned above, Embodiment 2 is based on the grid slicing device and the continuous grid of Embodiment 1. The difference is that six grooves 8 are arranged on the surface of the second traction roller 22 in the circumferential direction, and the grid conveyor belts 6 are arranged in cooperation one by one. In the groove 8, three grid conveyor belts 6 are formed into two groups, and are used as bottom brackets to export two rows of unit grids.

[0054] The sharding method includes the following steps:

[0055] S1: Lead the continuous grid into the roller gap of the first pair of rollers 1, the positioning protrusion 7 of the first traction roller 11 is socketed with the first positioning hole d and the second positioning hole e of the continuous grid, and the active traction continues Grid feeding, the first cutter roller 12 axial first cutter 4 cuts the tangent line a between the frame of the continuous grid, and the unit grid in the continuous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com