Aluminum alloy material production technology

An aluminum alloy material and production process technology, applied in metal processing equipment, manufacturing tools, mechanical cleaning, etc., can solve the problems of products that cannot meet the needs of use, easy to change the metallographic structure of aluminum alloys, and affect the performance of aluminum alloy materials, etc. Avoid secondary remelting process, improve the effect of refining, improve the effect of alloying degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below:

[0037] A production process of an aluminum alloy material, comprising the following steps:

[0038] S1. Melting furnace smelting: Pour the electrolytic aluminum liquid into the melting furnace, add solid charge into the melting furnace, add an intermediate alloy that meets the ratio requirements according to the alloy composition produced and the weight of the aluminum liquid, and take samples to pre-analyze the composition; directly use electrolysis Aluminum liquid is used as raw material for the production of aluminum alloy. Due to the high initial temperature of electrolytic aluminum liquid, it can directly melt the added metal or alloy, which accelerates the dissolution and diffusion of elements, improves the degree of alloying, avoids the secondary remelting process, and reduces the amount of metal Burning loss, reducing energy consumption and pollution emissions;

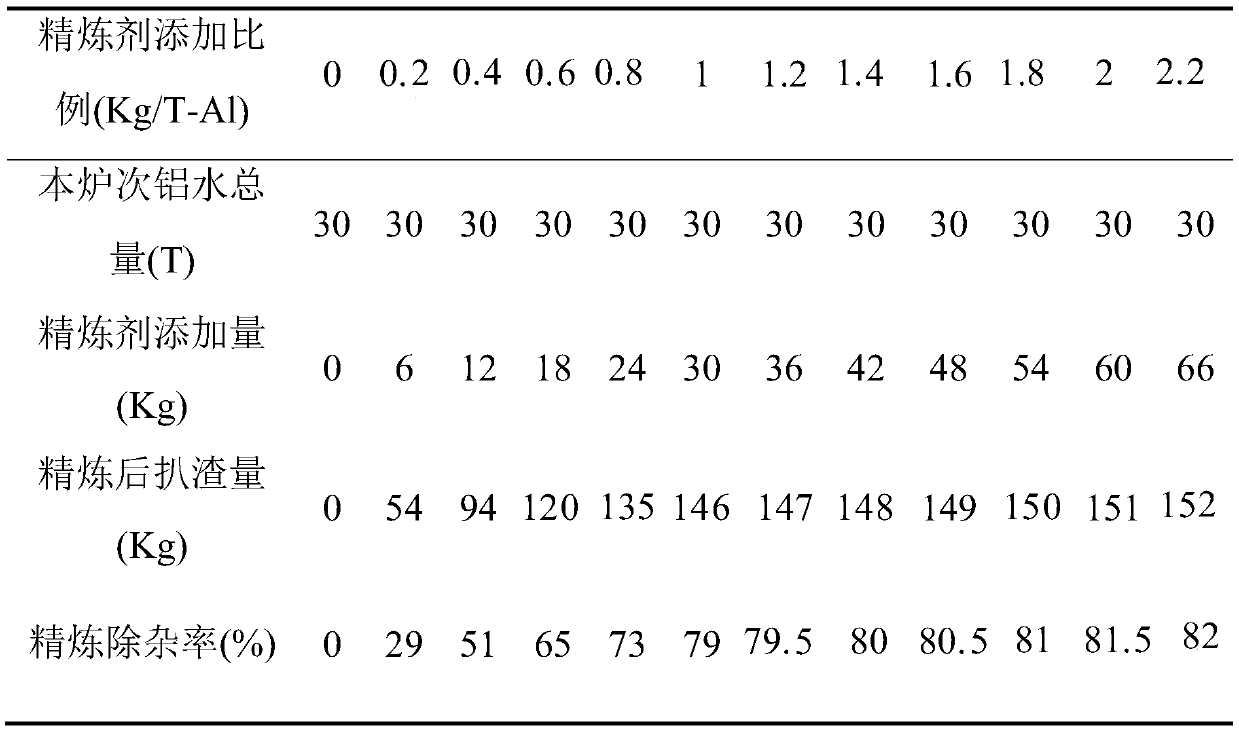

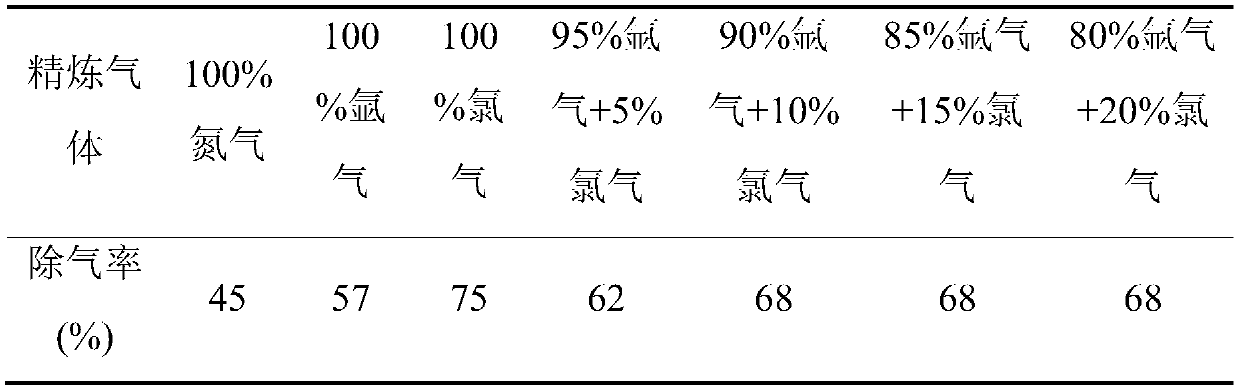

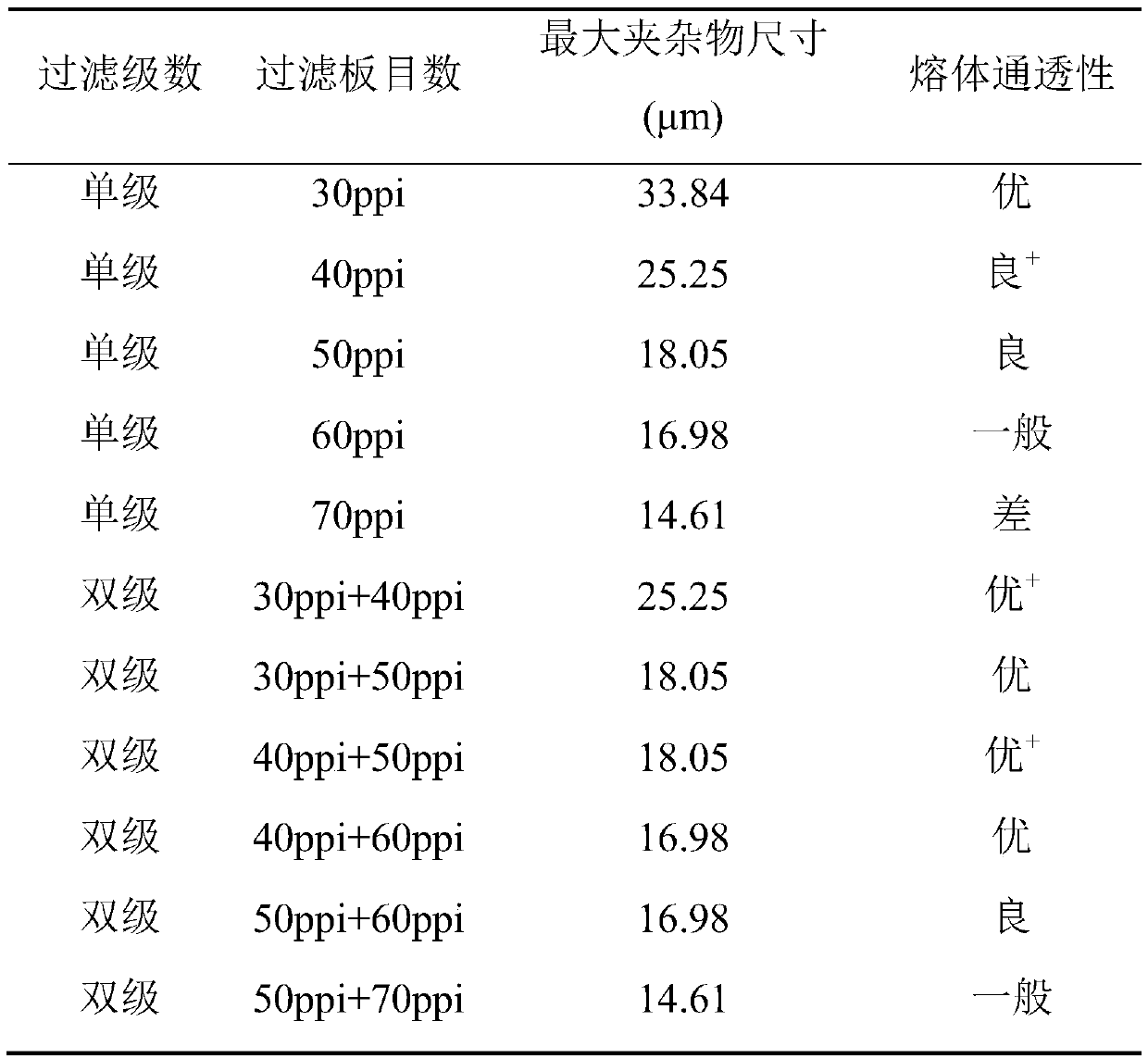

[0039] S2. Primary refining of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com