LED dispensing method

A dispensing and glue technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as overflowing glue, falling off of LED lights, reducing production efficiency, etc., to achieve the effect of simple process, increased adhesion, and high product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

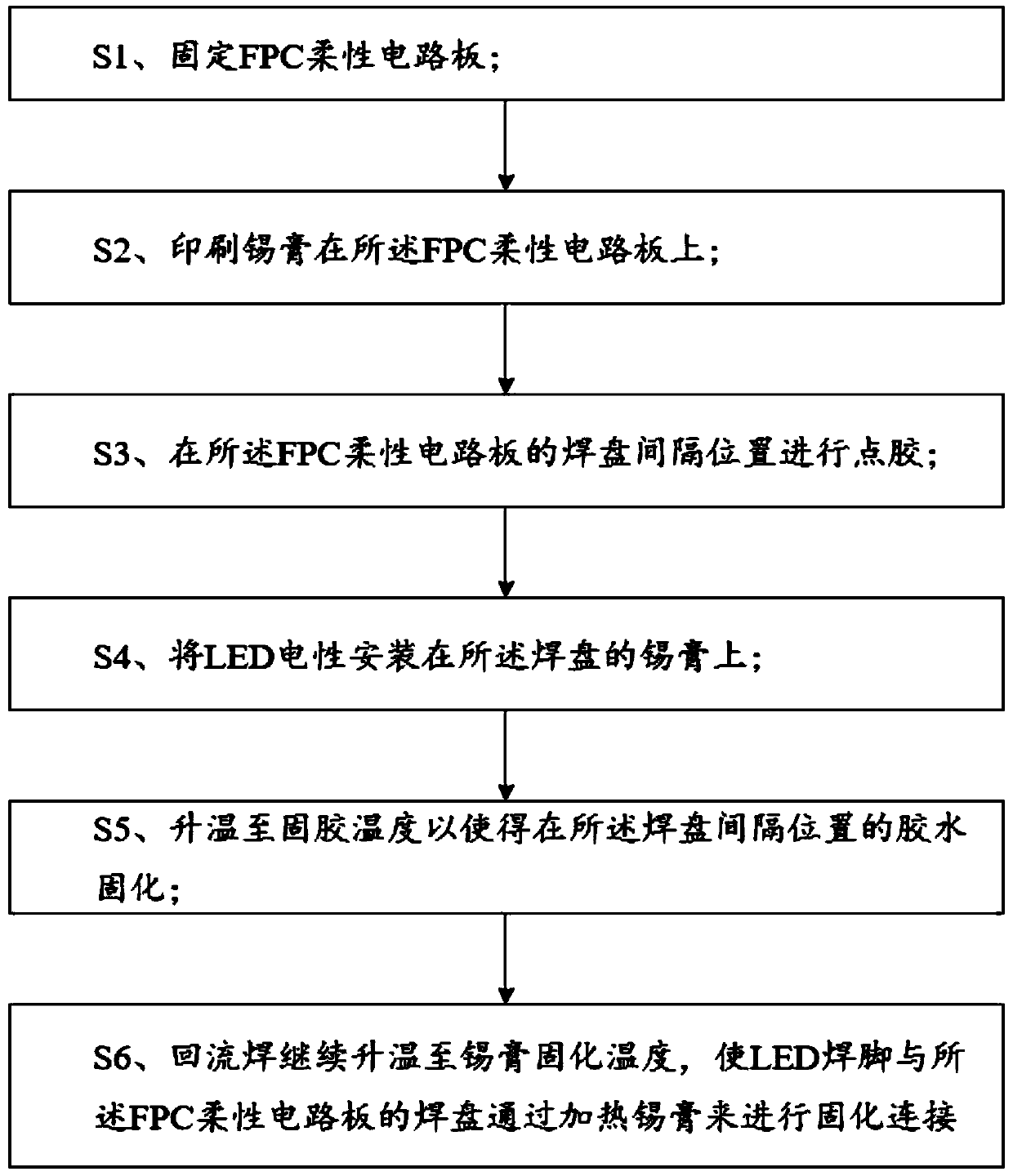

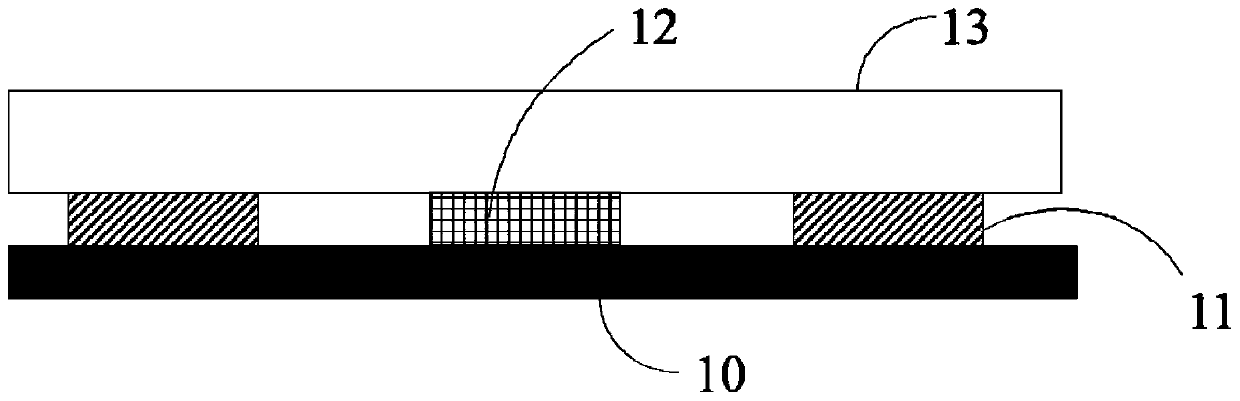

[0028] First, please refer to Figure 1-2 According to the embodiment of the present invention, a method for LED dispensing is provided, which includes the following steps:

[0029] S1, fixing the FPC flexible circuit board 10;

[0030] S2, printing solder paste 11 on the FPC flexible circuit board 10;

[0031] S3, dispensing glue at the spacing between the pads of the FPC flexible circuit board 10;

[0032] S4, electrically installing the LED 13 on the solder paste 11 of the pad;

[0033] S5, heating up to a curing temperature of 130° C. so that the glue 12 at the position between the pads is cured, and the curing time is 60 s;

[0034] S6. The reflow soldering continues to heat up to the solidification temperature of the solder paste 11 at 230° C., so that the soldering leg of the LED 13 and the pad of the FPC flexible circuit board 10 are cured and connected by heating the solder paste 11 . The curing temperature of the solder paste is higher than the curing temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com