Granulation equipment for pig feed processing

A technology of pelletizing equipment and pig feed, applied in lighting and heating equipment, feed, metal processing and other directions, can solve problems such as affecting the speed and effect of pig feed forming, pig feed pellets not having drying effect, and clogging of feed forming holes. , to achieve the effect of broad market application prospects, prolonging the falling speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

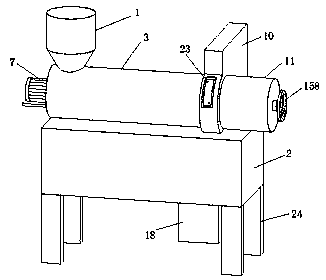

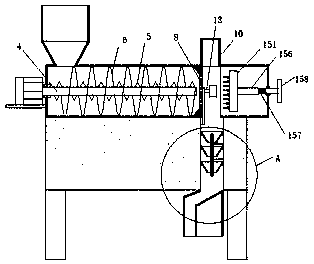

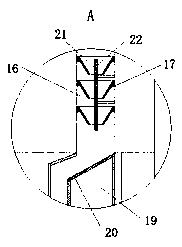

[0036] Such as Figure 1-5 As shown, a granulation equipment for pig feed processing includes a feed hopper 1, a discharge box 2 and a horizontally arranged granulation cylinder 3. The upper side wall of the granulation cylinder 3 is connected with the feed hopper 1 and the granulation cylinder 3. There is a stirring shaft 4 inside, the outer wall of the stirring shaft 4 is fixed with crushing teeth 5 and helical blades 6, the outside of the stirring shaft 4 is connected with the output end of the first motor 7 through a bearing seat, and the right port of the granulating cylinder 3 is fixed with a Granulating plate 8, the surface of granulating plate 8 is evenly provided with forming holes 9, the right side of granulating cylinder 3 is provided with motor cover 10 and cleaning cylinder 11, and the front side of motor cover 10 is provided with glass door 23, and the motor cover The inside of 10 is provided with second motor 12, and the output end of second motor 12 is provided...

Embodiment 2

[0040] Such as Figure 4-7 As shown, a granulation equipment for pig feed processing includes a feed hopper 1, a discharge box 2 and a horizontally arranged granulation cylinder 3. The upper side wall of the granulation cylinder 3 is connected with the feed hopper 1 and the granulation cylinder 3. There is a stirring shaft 4 inside, the outer wall of the stirring shaft 4 is fixed with crushing teeth 5 and helical blades 6, the outside of the stirring shaft 4 is connected with the output end of the first motor 7 through a bearing seat, and the right port of the granulating cylinder 3 is fixed with a Granulating plate 8, the surface of granulating plate 8 is evenly provided with forming holes 9, the right side of granulating cylinder 3 is provided with motor cover 10 and cleaning cylinder 11, and the front side of motor cover 10 is provided with glass door 23, and the motor cover The inside of 10 is provided with second motor 12, and the output end of second motor 12 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com