Plastic gate valve and preparation method thereof and application

A plastic and gate technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problem of not giving plastic gate valves, etc., and achieve the effect of reducing valve weight, energy consumption, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

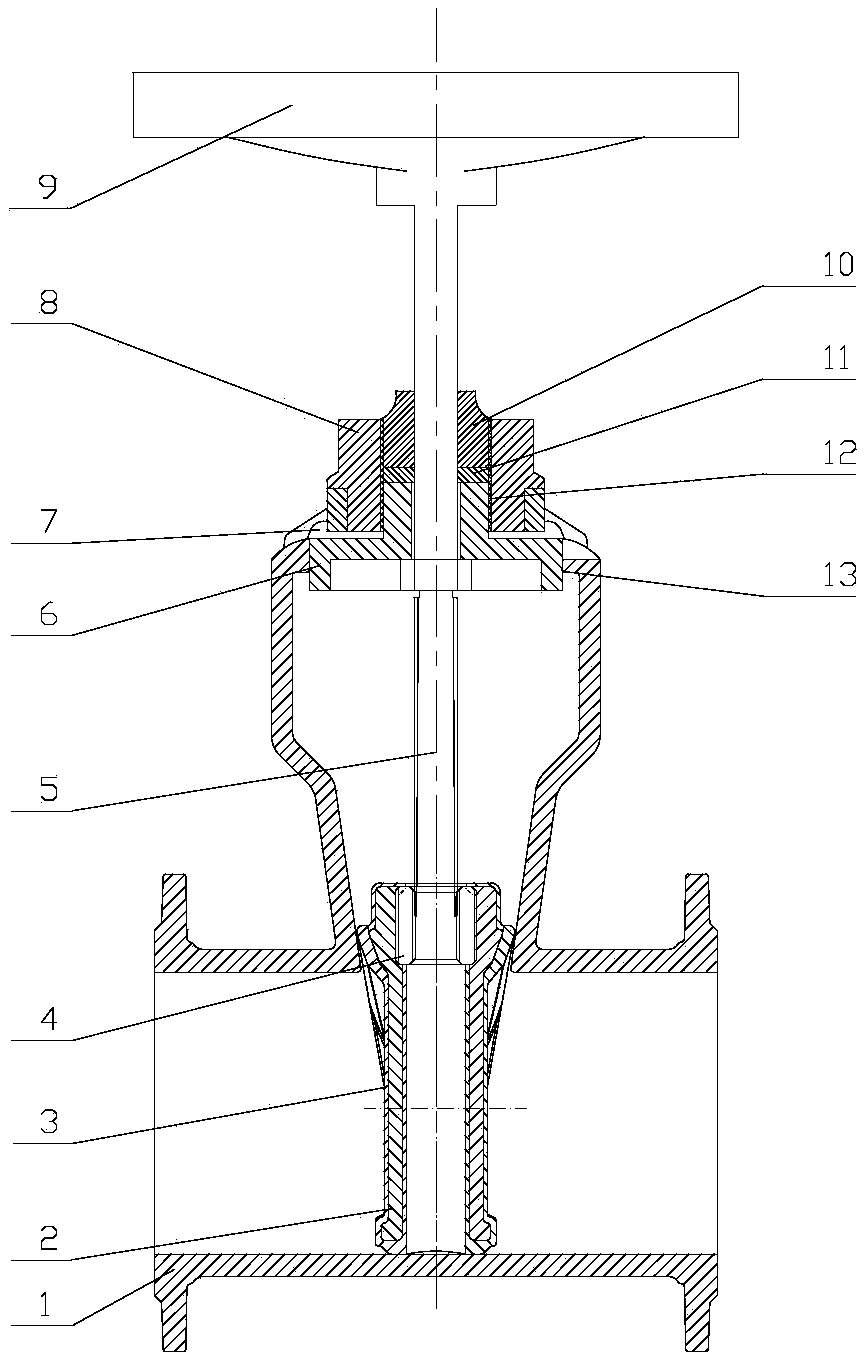

[0029] Plastic gate valve of the present invention, as attached figure 1 As shown, it includes valve body 1, bonnet 6, gate plate and valve stem 5. The valve body is inverted T-shaped and has a hollow structure; the gate plate is located in the lower part of the valve body; one end of the valve stem is connected to the gate plate, and the other end is connected to the handwheel 9 connections; the hand wheel is set outside the valve body; the top of the valve body is provided with a bonnet connection port that matches the bonnet; the bonnet is fixedly connected to the valve body and the bonnet connection port is closed; the gate includes a gate frame 2 , the gate frame is arranged perpendicular to the bottom of the valve body, and closes the lateral part of the bottom of the gate; the outer surface of the gate is wrapped with a gate rubber 3 .

[0030] The bonnet and the gate are fixedly connected through the gate nut 4, and the gate nut is arranged on the outer surface of the ...

Embodiment 2

[0034] The gate frame of the plastic gate valve is made of plastic material, and the plastic material of the gate frame includes nylon or polyphenylene sulfide and glass fiber with a weight ratio of 35:65.

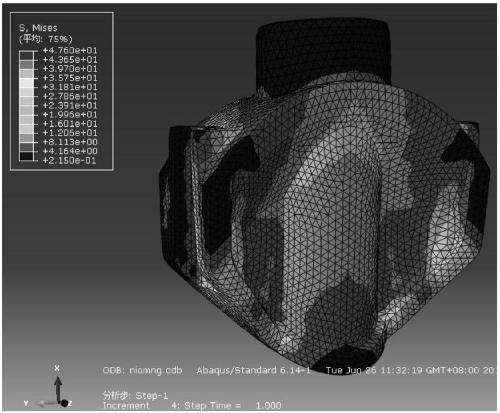

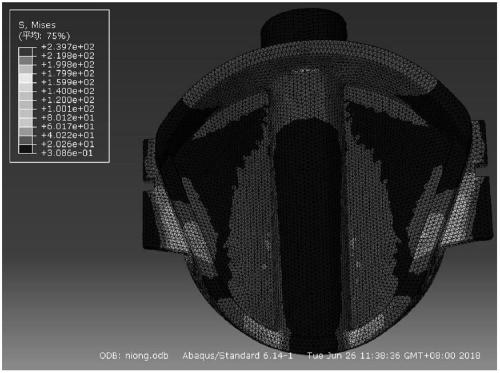

[0035] The tensile strength of the gate frame is 200-210MPA.

[0036] The preparation process comprises the following steps:

[0037] The gate mold is installed on the injection molding machine, and the plastic is heated and melted. The temperature is raised in five stages. The temperature of the five stages is 260, 270, 280, 290, and 298°C. The injection pressure of the injection molding machine is 12MPA, and the pressure is 9MPA. The pressure holding time is 5 seconds; the molten plastic is pressed into the mold by the screw, and cooled and shaped.

Embodiment 3

[0039] Install the gate plate prepared in Example 2 on a DN100 valve, close the valve and put it into the valve testing equipment, inject a certain water pressure into one side of the valve, keep it for 10 minutes, and check whether the water pressure decreases, that is, the valve Whether it leaks.

[0040]

[0041] Through the test, the plastic gate instead of the cast iron gate compared with the ordinary plastic gate, the plastic gate of the present invention can keep the water pressure on both sides of the gate constant, and the plastic gate of the present invention can be installed in the water pressure of 1.6MPa. on the valve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com