Method and system for testing stress-strain of hydrodynamic retarder

A hydraulic reducer, stress-strain technology, applied in the field of hydraulic reducer, can solve the problems of inability to accurately test stress and strain, and achieve the effects of accurate selection, improved test accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

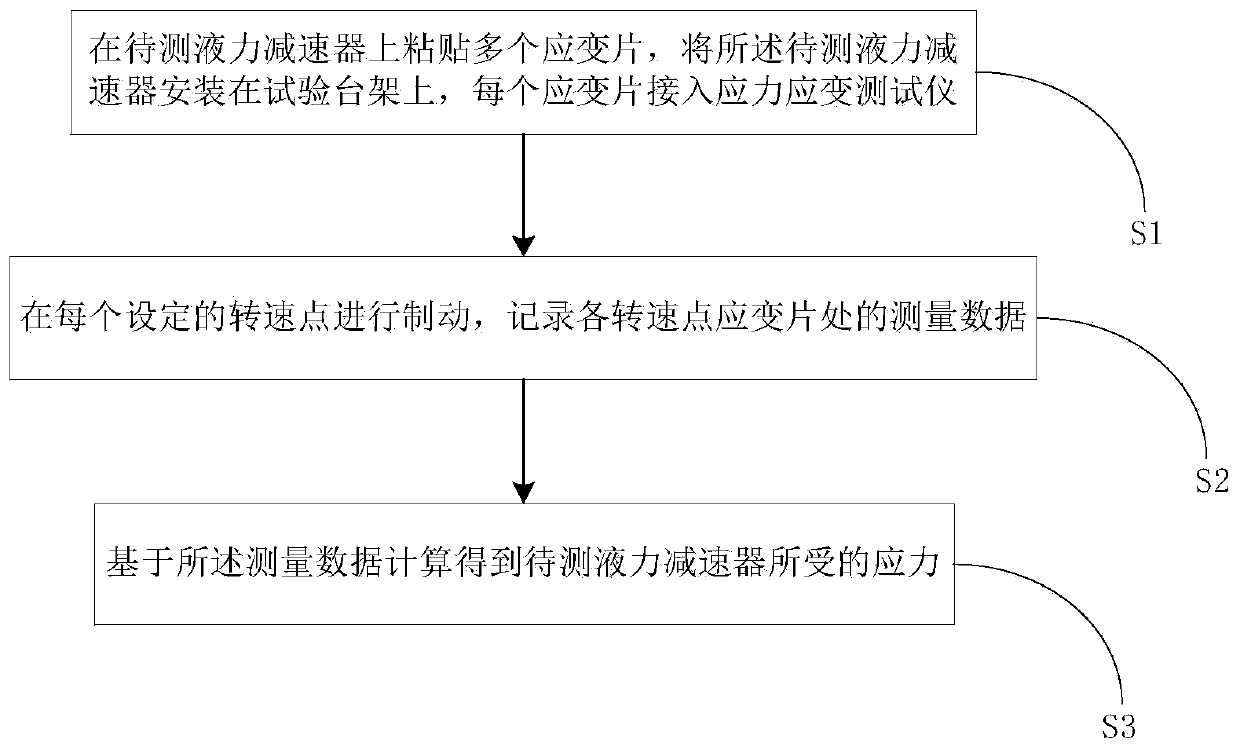

[0062] In order to achieve a technological breakthrough in the hydraulic retarder, it is necessary to master the structural strength test verification method of the hydraulic retarder based on optimal design, and establish a structural stress-strain test method for extreme braking conditions. Therefore the present invention provides a kind of test method of hydraulic retarder stress strain, such as figure 1 shown, including:

[0063] Step S1, pasting a plurality of strain gauges on the hydraulic retarder to be tested, installing the hydraulic retarder to be tested on the test bench, and connecting each strain gauge to a stress-strain tester;

[0064] Step S2, perform braking at each set rotational speed point, and record the measurement data of all strain gauges at said rotational speed point;

[0065] Step S3, calculating the stress on the hydraulic retarder to be tested based on the measurement data;

[0066] The measured data includes: torque, temperature and strain value...

Embodiment 2

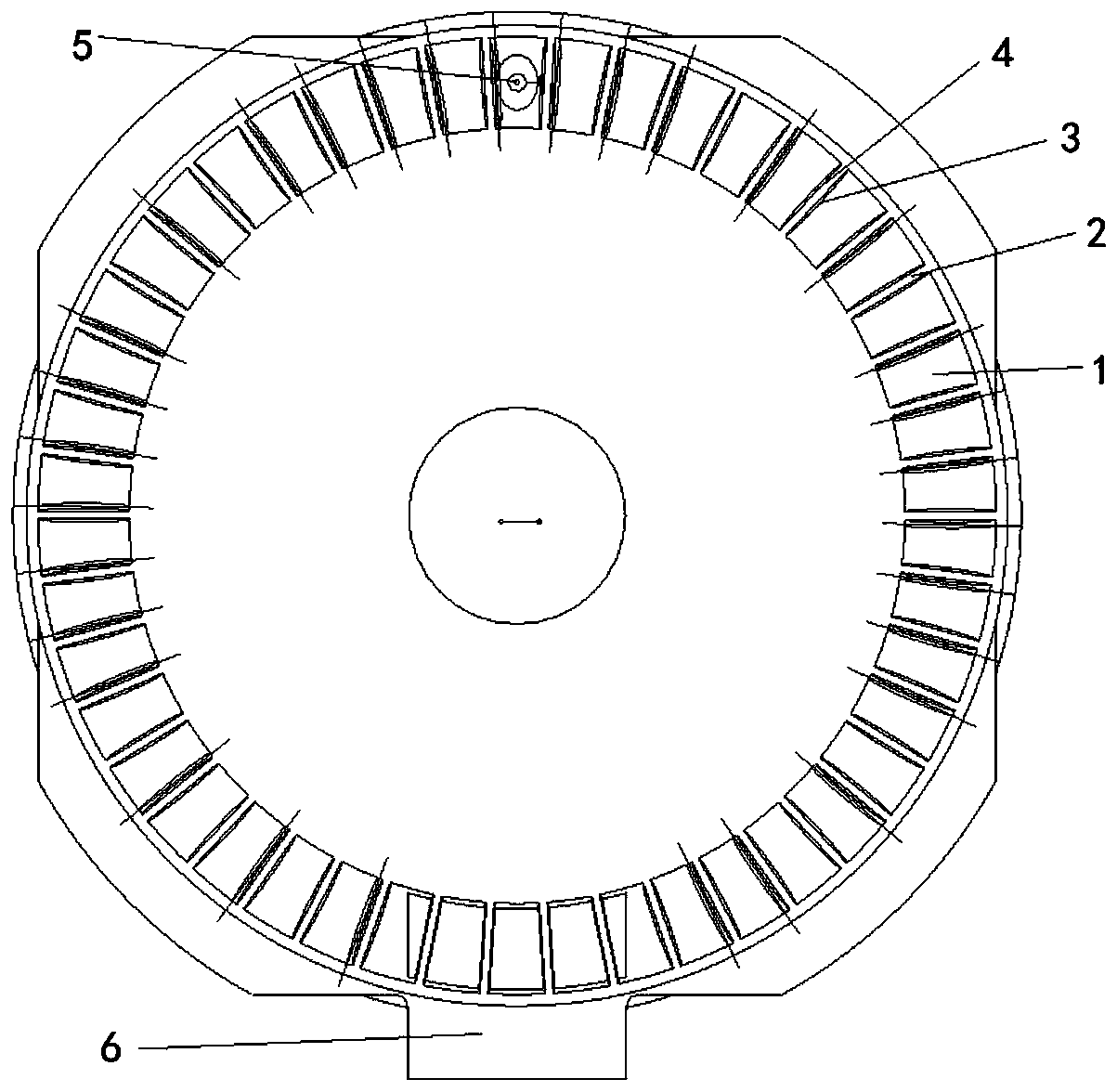

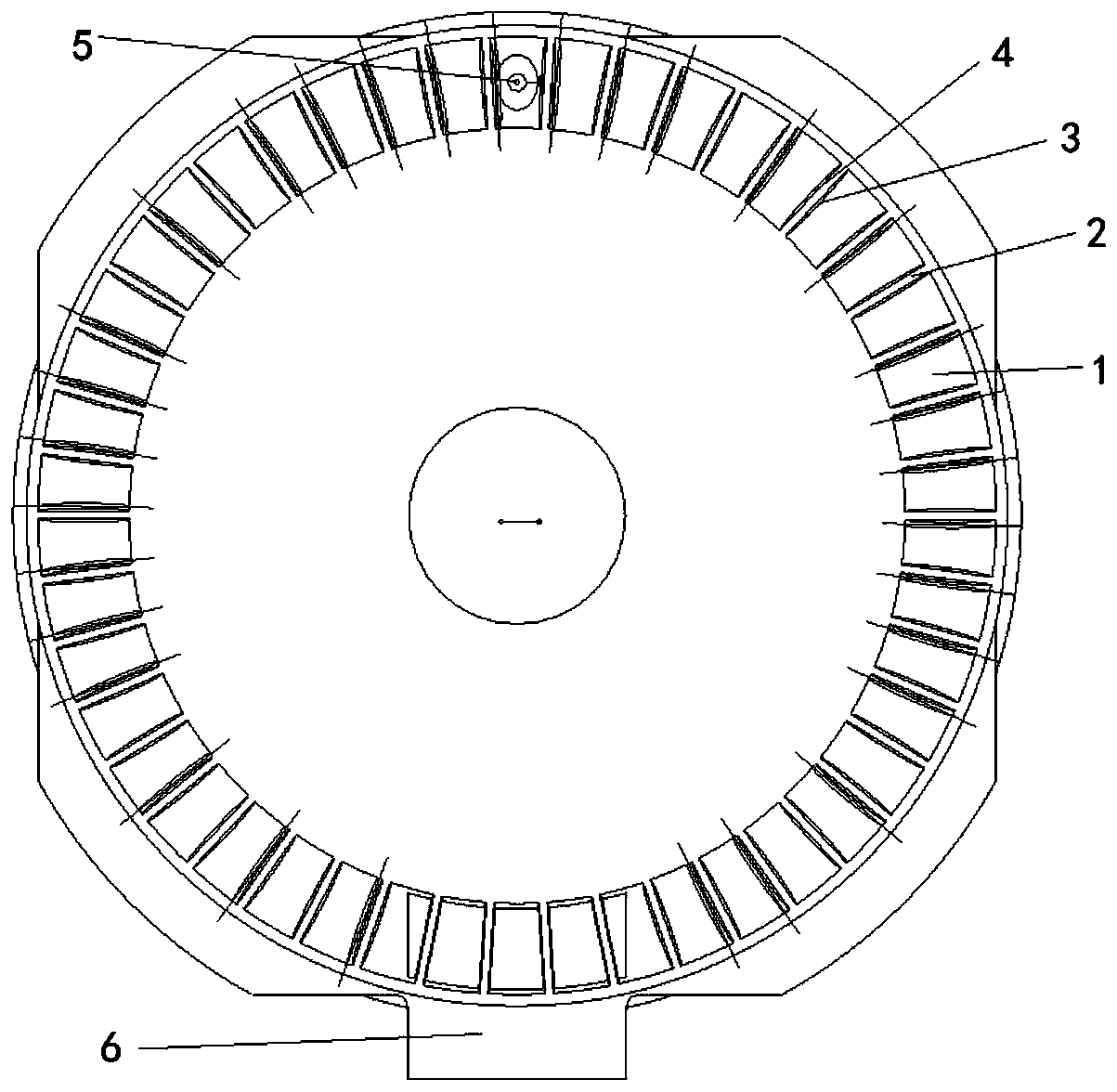

[0086] In order to further illustrate the measurement method provided by the present invention, the cast aluminum 101A hydraulic retarder is taken as an example for illustration in this embodiment. The application environment of the cast aluminum 101A hydraulic reducer is oil mist and instantaneous high temperature environment of nearly 120°C. The external dimensions of the fixed wheel of the hydraulic reducer are: outer diameter D = 480mm, diameter of the working chamber d = 420mm, thickness of the fixed wheel H = 36mm, When working, the cavity is filled with 10W-40 transmission oil, and the oil filling volume depends on the braking conditions. The emergency braking condition is the maximum oil filling volume, and the oil filling rate is nearly 90%.

[0087] The stress-strain test is carried out on the cast aluminum 101A hydraulic reducer fixed wheel, which specifically includes the following steps:

[0088] (1) Select the strain point of the test

[0089] Such as Figure 2...

Embodiment 3

[0114] Based on the same inventive concept, the present invention also provides a stress-strain testing system for a hydraulic retarder, including:

[0115] Assembling a module for pasting a plurality of strain gauges on the hydraulic retarder to be tested, installing the hydraulic retarder to be tested on the test bench, and connecting each strain gauge to a stress-strain tester;

[0116]The measurement module is used for braking at each set rotational speed point, and records the measurement data of all strain gauges at the said rotational speed point;

[0117] A calculation module, configured to calculate the stress on the hydraulic retarder to be tested based on the measurement data;

[0118] The measured data includes: torque, temperature and strain values.

[0119] In an embodiment, the assembly module includes:

[0120] determining an alternative sub-module for determining an alternative strain gauge attachment point on the fixed wheel blade of the hydraulic retarder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Maximum strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com