Processing method of a laminate

A processing method and a laminated body technology, applied in metal processing equipment, manufacturing tools, electrical solid devices, etc., can solve problems such as quality reduction, image sensor chip defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the processing method of the laminated body which concerns on embodiment of this invention is demonstrated in detail, referring drawings.

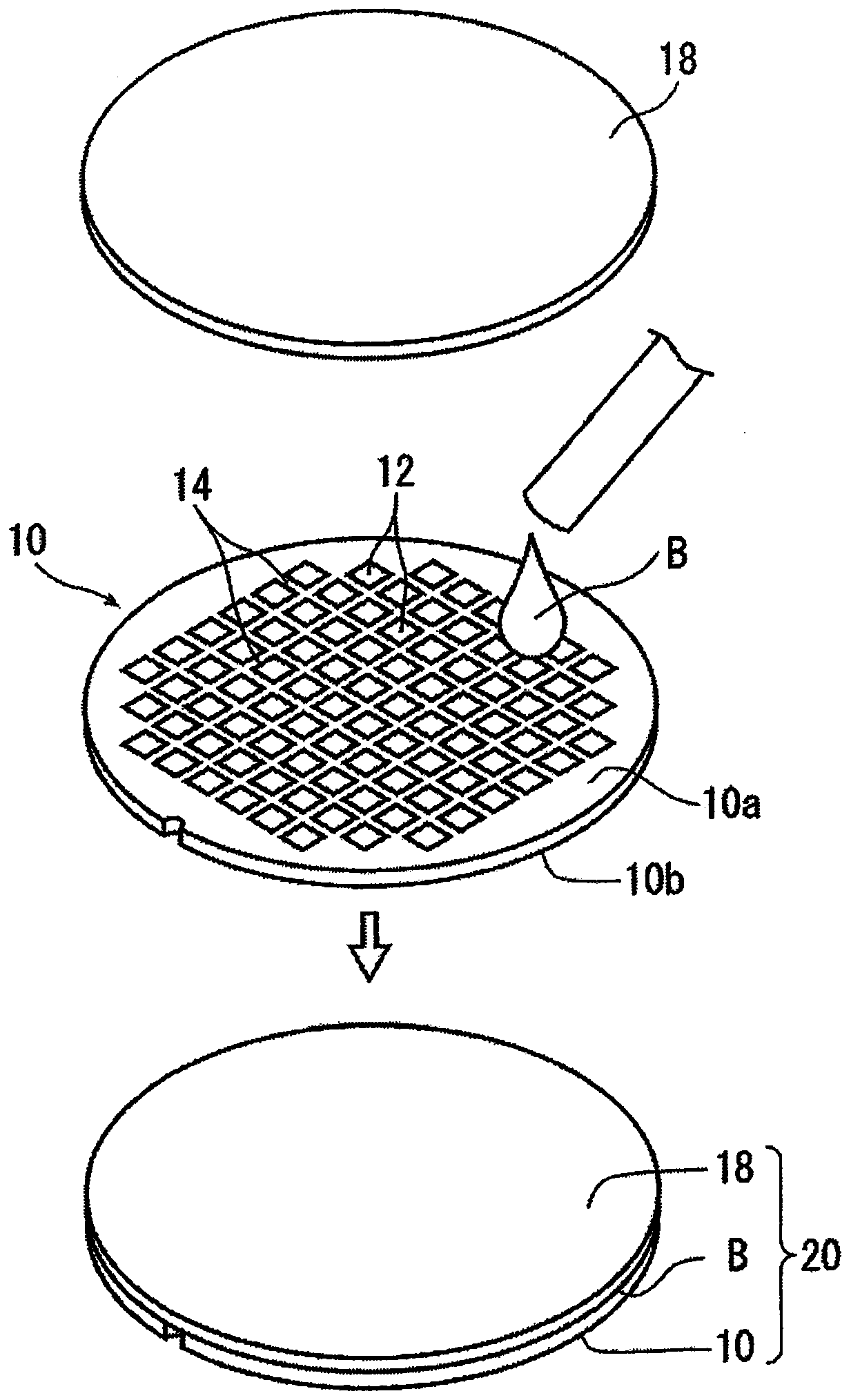

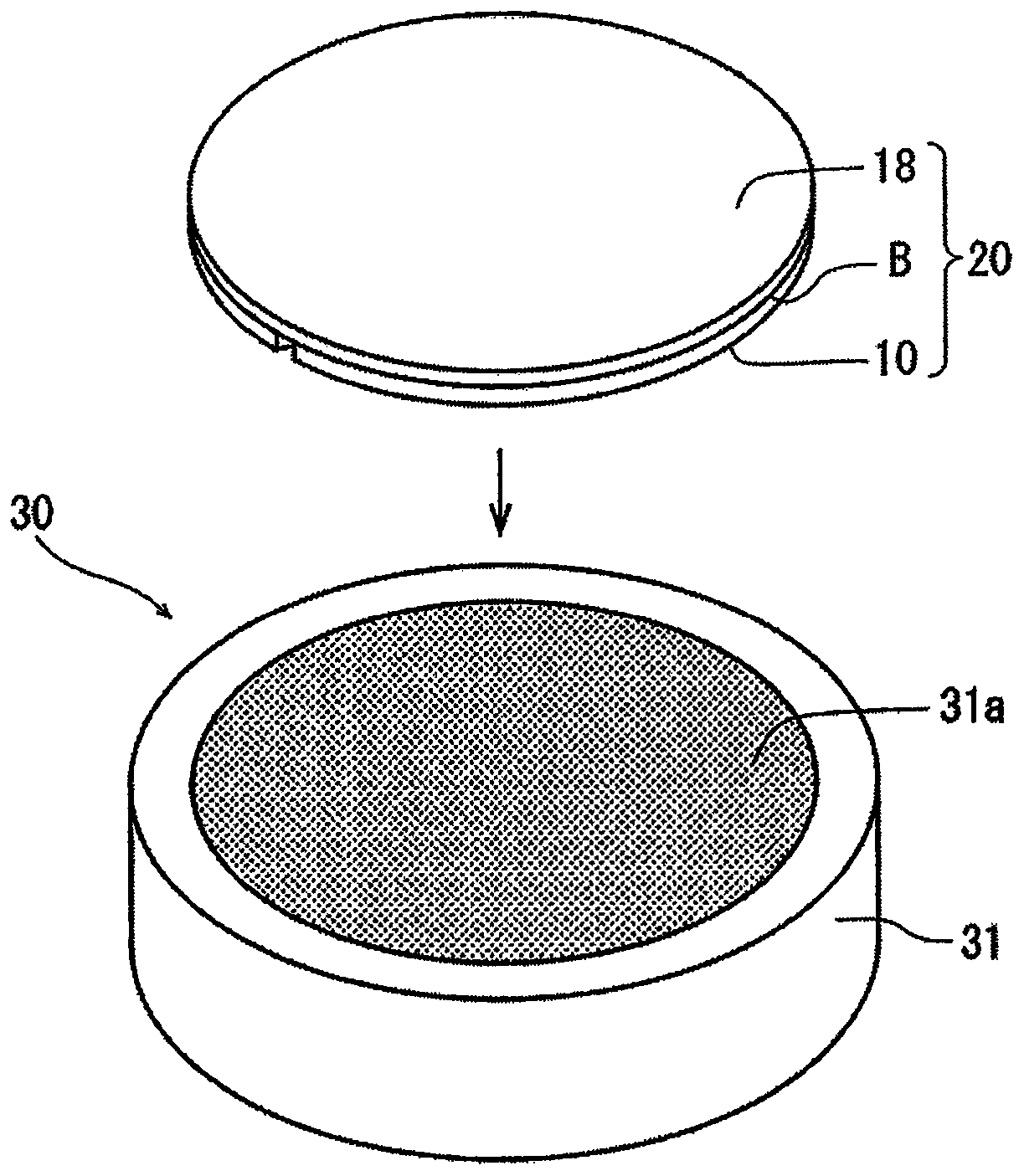

[0024] Such as figure 1 As shown, first, for example, a wafer 10 made of silicon (Si) and a transparent glass substrate 18 are prepared. The wafer 10 is divided by a plurality of intersecting dividing lines 14 and a plurality of image sensors (CMOS) 12 are formed on the front surface 10a. . Once the wafer 10 and the glass substrate 18 are prepared, a transparent adhesive (resin bond) B is dropped on the front surface 10 a of the wafer 10 to bond the glass substrate 18 . In this way, the wafer 10 and the glass substrate 18 are integrated through the adhesive layer B composed of the above-mentioned adhesive B to form a laminated body 20 (refer to figure 1 lower part of ).

[0025] (cutting groove forming process)

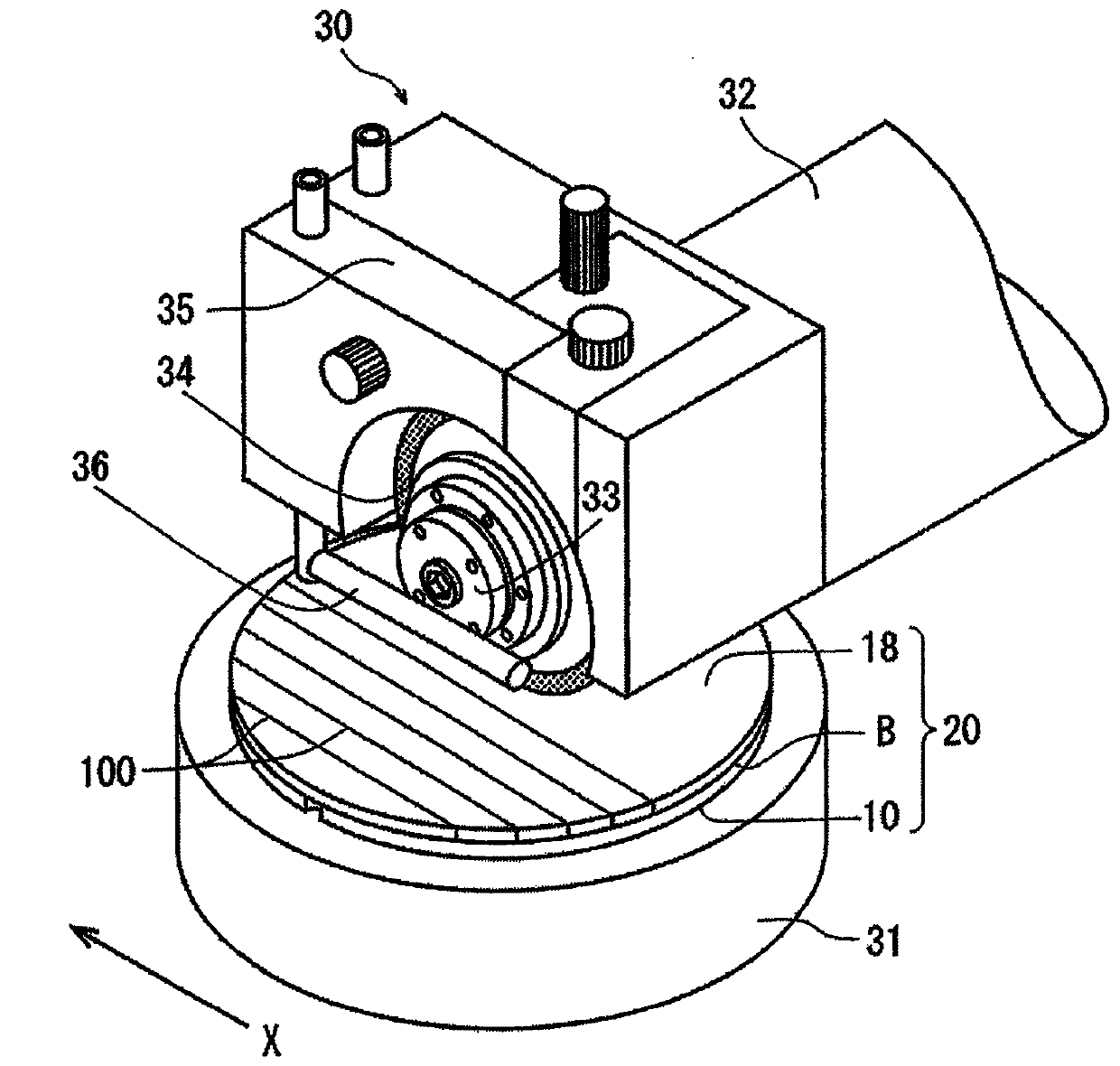

[0026] Once the laminated body 20 is formed as described above, the cutting groove forming step is perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com