Graphene battery structure

A graphene and graphene suspension technology, applied in secondary batteries, battery electrodes, structural parts, etc., can solve the problems of poor gas heat dissipation, inability to discharge batteries, etc., to achieve stable overall structure, high overall charge and discharge efficiency, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

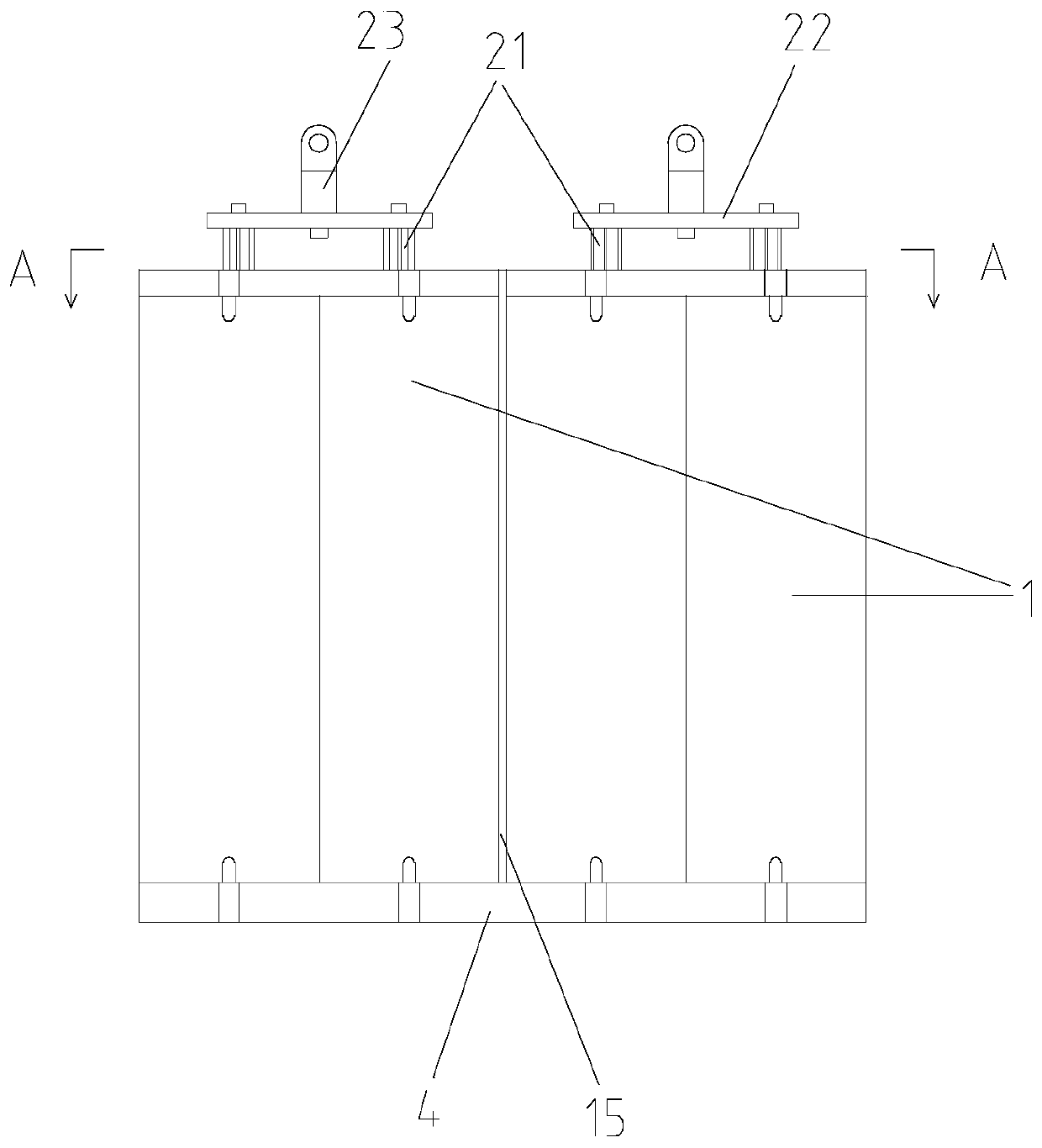

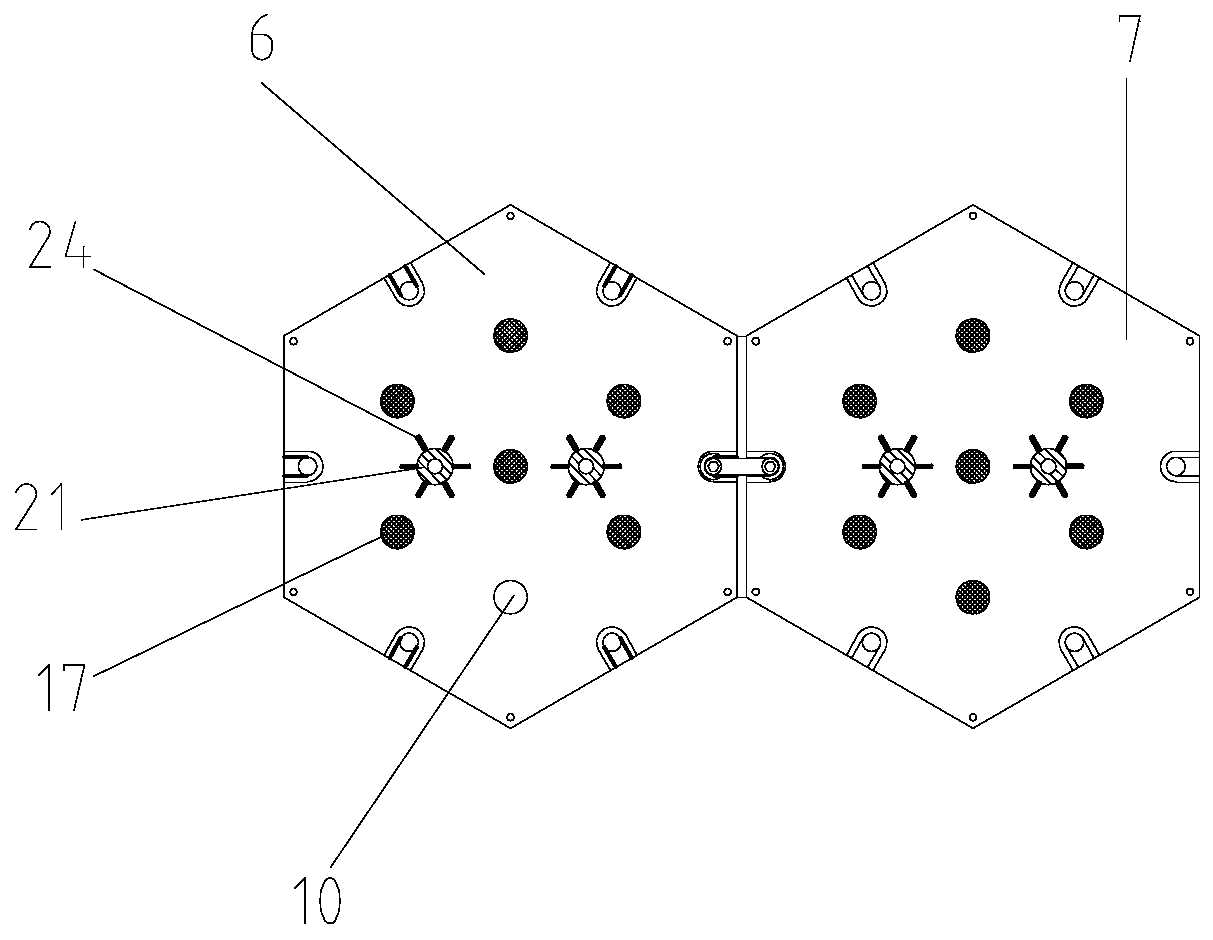

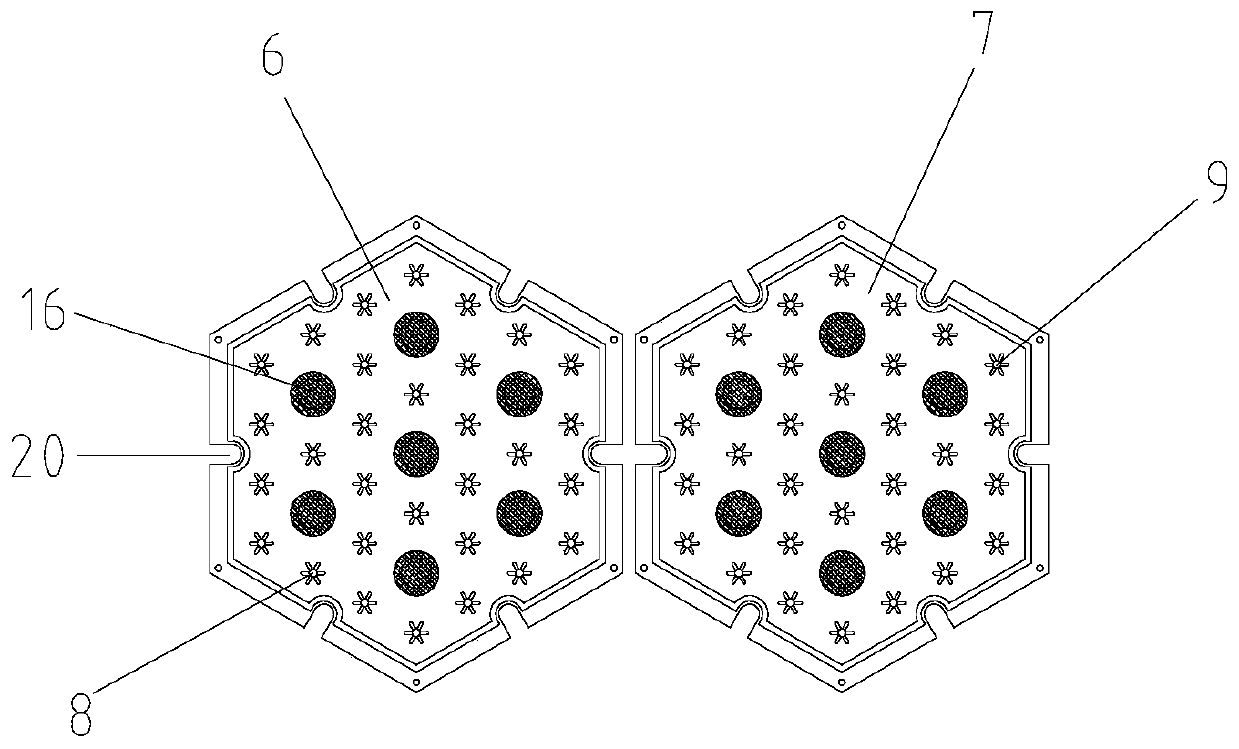

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 A graphene battery structure is shown, comprising two microporous ceramic substrates 1 distributed in a columnar shape, a number of electrolyte through holes 2, a number of exhaust holes 3 are arranged in the microporous ceramic substrate, microporous ceramic substrates in the microporous ceramic substrate 1 The holes are filled with graphene particles, the top surface, the bottom surface and the outer surface of the microporous ceramic substrate 1 are provided with an insulating layer, the lower ends of the two microporous ceramic substrates 1 are provided with a base 4, and two connection cavities 5 are provided on the base , the lower ends of the electrolyte through-holes in the two microporous ceramic substrates communicate with the two connection cavities r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com