Separation reagent for emulsified oily wastewater, preparation method and separation method

A separation method and medicament technology, applied in the field of separation medicaments for emulsified oily wastewater, can solve the problems of large power consumption, environmental secondary pollution, and affecting extraction efficiency, so as to reduce environmental hazards, avoid secondary pollution, and achieve good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a separation agent for emulsifying oily wastewater, comprising the steps of:

[0039] S1. After mixing the switching solvent with water, a liquid with an oil-water interface is obtained;

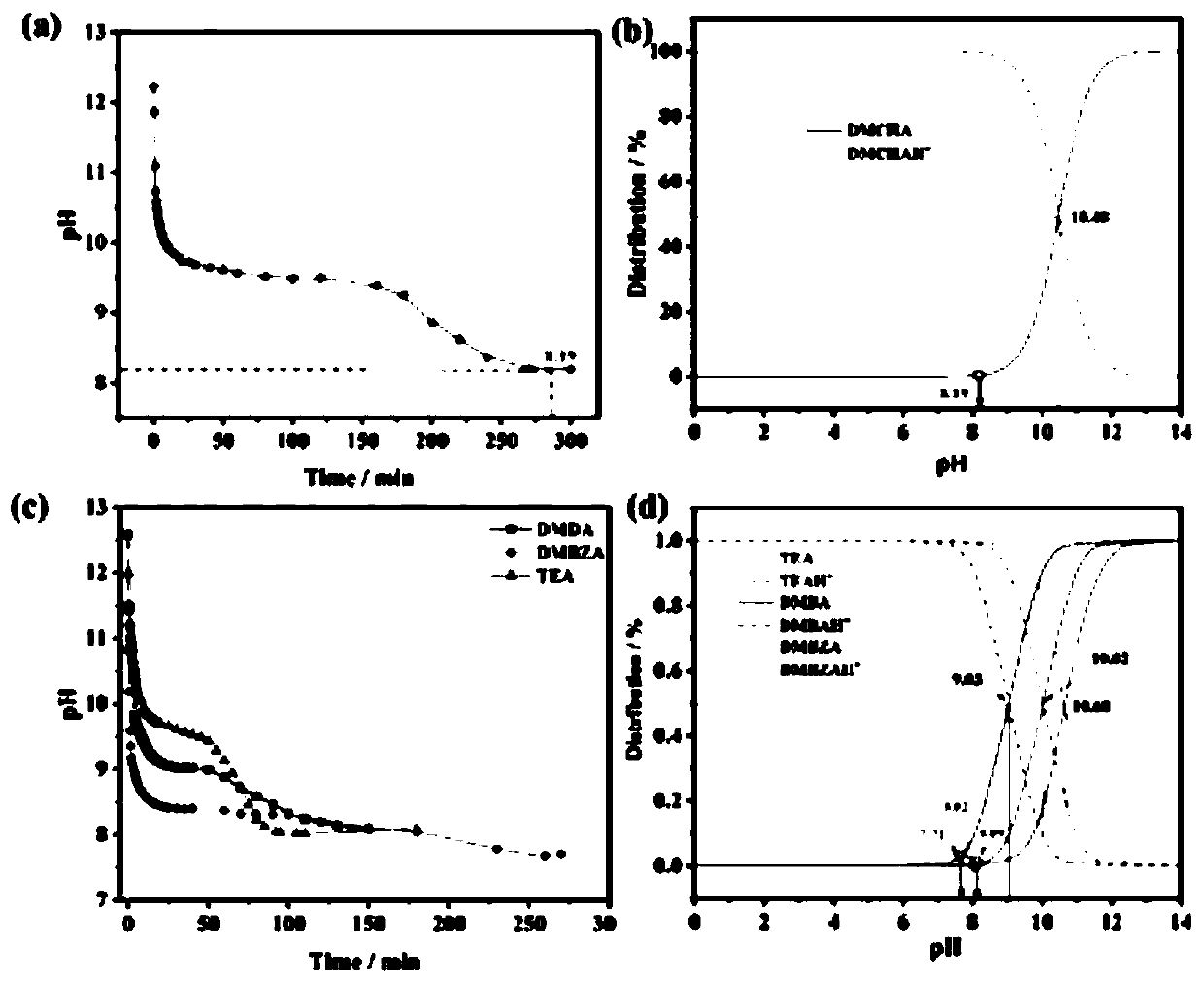

[0040] S2. Introduce carbon dioxide into the liquid with the oil-water interface until the pH value of the liquid is stable to obtain a bicarbonate solution containing a switch solvent.

[0041] Further, the step S2 also includes: injecting carbon dioxide into the liquid at a rate of 300 mL / min at 25°C.

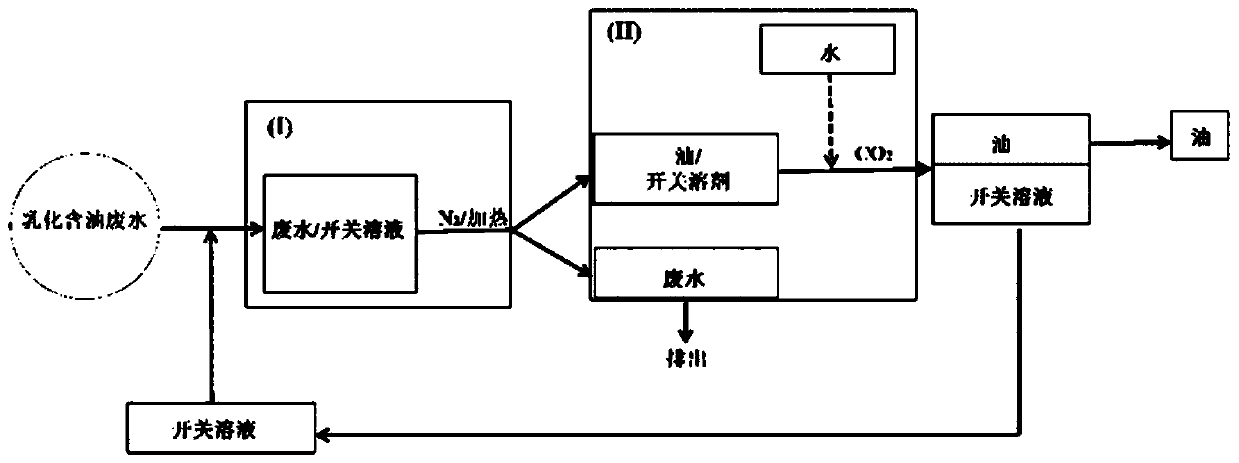

[0042] A separation method for emulsified oily wastewater, comprising the steps of:

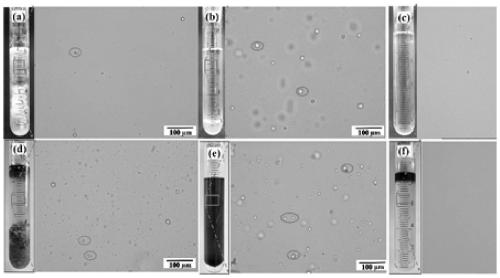

[0043] A. After mixing the emulsified oily waste water and the separation agent, feed nitrogen to obtain a clear aqueous solution phase and a mixed oil phase containing oil and switching solvent;

[0044] B. After mixing the mixed oil phase and water, carbon dioxide is introduced until the volume of the oil phase is stable to obtain a switch solution, and after purification,...

Embodiment 1

[0048] A separation agent for emulsifying oily wastewater, the separation agent is a bicarbonate solution of a switching solvent; the bicarbonate solution of a switching solvent is made by reacting a switching solvent, carbon dioxide and water.

[0049]The preparation method of the separation agent in this embodiment includes steps: S1. After mixing the switching solvent and water, a liquid with an oil-water interface is obtained; S2. Introducing carbon dioxide into the liquid with an oil-water interface until the pH value of the liquid Stable to give a bicarbonate solution containing the switch solvent.

Embodiment 2

[0051] A separation agent for emulsifying oily wastewater, the separation agent is a bicarbonate solution of a switching solvent; the bicarbonate solution of the switching solvent is made by reacting a switching solvent, carbon dioxide and water; the water is used for The amount of water with which the switch solvent produces an oil-water interface.

[0052] The preparation method of the separation agent of this embodiment includes steps: S1. After mixing the switching solvent and water, a liquid with an oil-water interface is obtained; S2. Introducing carbon dioxide into the liquid with an oil-water interface until the pH of the liquid is The value is stable, and a bicarbonate solution containing the switch solvent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com