Cleanable wide-width air filtering composite membrane as well as preparation method and application thereof

An air filtration and composite membrane technology, applied in the field of materials, can solve the problems of filter materials that cannot be washed with water, poor protection effect, and short service life, and achieve the effects of ensuring composite mechanical strength and air permeability, convenient cleaning, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

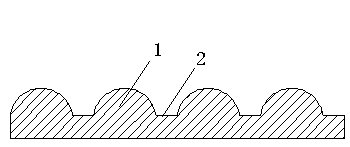

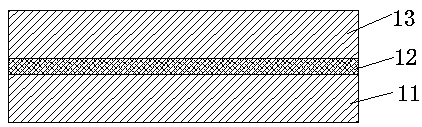

[0031] This embodiment provides a washable wide-width air filtration composite membrane, which includes a membrane body and corrugated or linear ultrasonic indentations evenly arranged on the membrane body. The thickness of the membrane body without ultrasonic indentations is greater than that with ultrasonic indentations. The thickness of the membrane material body with traces, the membrane material body consists of polyester (PET) cloth, PET heavy ion microporous membrane layer and polyester (PET) cloth from bottom to top, and polyester (PET) cloth is composited on PET heavy The upper surface and the lower surface of the ion microporous membrane layer.

[0032] The PET heavy ion microporous membrane layer is composed of two or more single pieces of PET heavy ion microporous membranes. The splicing method of the single PET heavy ion microporous membrane is ultrasonic composite. There is a 1-2 cm overlapping area at the splicing, and the width of the polyester (PET) cloth is c...

specific Embodiment 2

[0038] This embodiment provides a washable wide-width air filtration composite membrane, which includes a membrane body and corrugated or linear ultrasonic indentations evenly arranged on the membrane body. The thickness of the membrane body without ultrasonic indentations is greater than that with ultrasonic indentations. The thickness of the membrane material body of the mark, the membrane material body consists of PET non-woven fabric, PET heavy ion microporous film layer and PET non-woven fabric from bottom to top, and PET non-woven fabric is composited on PET heavy ion microporous membrane layer by ultrasonic wave respectively. top and bottom surfaces of the film.

[0039] The PET heavy ion microporous membrane layer is composed of two or more single pieces of PET heavy ion microporous membranes. The splicing method of the single PET heavy ion microporous membrane is ultrasonic composite. There is a 1-2 cm overlapping area at the splicing point, and the width of the PET n...

specific Embodiment 3

[0045] This embodiment provides a washable wide-width air filtration composite membrane, which includes a membrane body and corrugated or linear ultrasonic indentations evenly arranged on the membrane body. The thickness of the membrane body without ultrasonic indentations is greater than that with ultrasonic indentations. The thickness of the membrane material body, the membrane material body consists of polypropylene (PP) cloth, PP heavy ion microporous membrane layer and polypropylene (PP) cloth from bottom to top, respectively top and bottom surfaces of the layer.

[0046] The PP heavy ion microporous membrane layer is composed of two or more pieces of PP heavy ion microporous membrane spliced together. The splicing method of the single PP heavy ion microporous membrane is ultrasonic composite. There is a 1-2 cm overlapping area at the splicing point, and the width of the polypropylene (PP) cloth is consistent with the width of the spliced heavy ion microporous membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com