Eddy current sensor machine tool online calibration device and method

A technology of eddy current sensor and calibration device, which is applied in the direction of metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of complex structure and high precision requirements of parts, achieve simple installation and operation, and improve fitting optimization The effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0032] Taking the current-type eddy current sensor as an example, the process of the forward stroke is mainly explained, and the process of the reverse stroke is the same as that of the forward stroke.

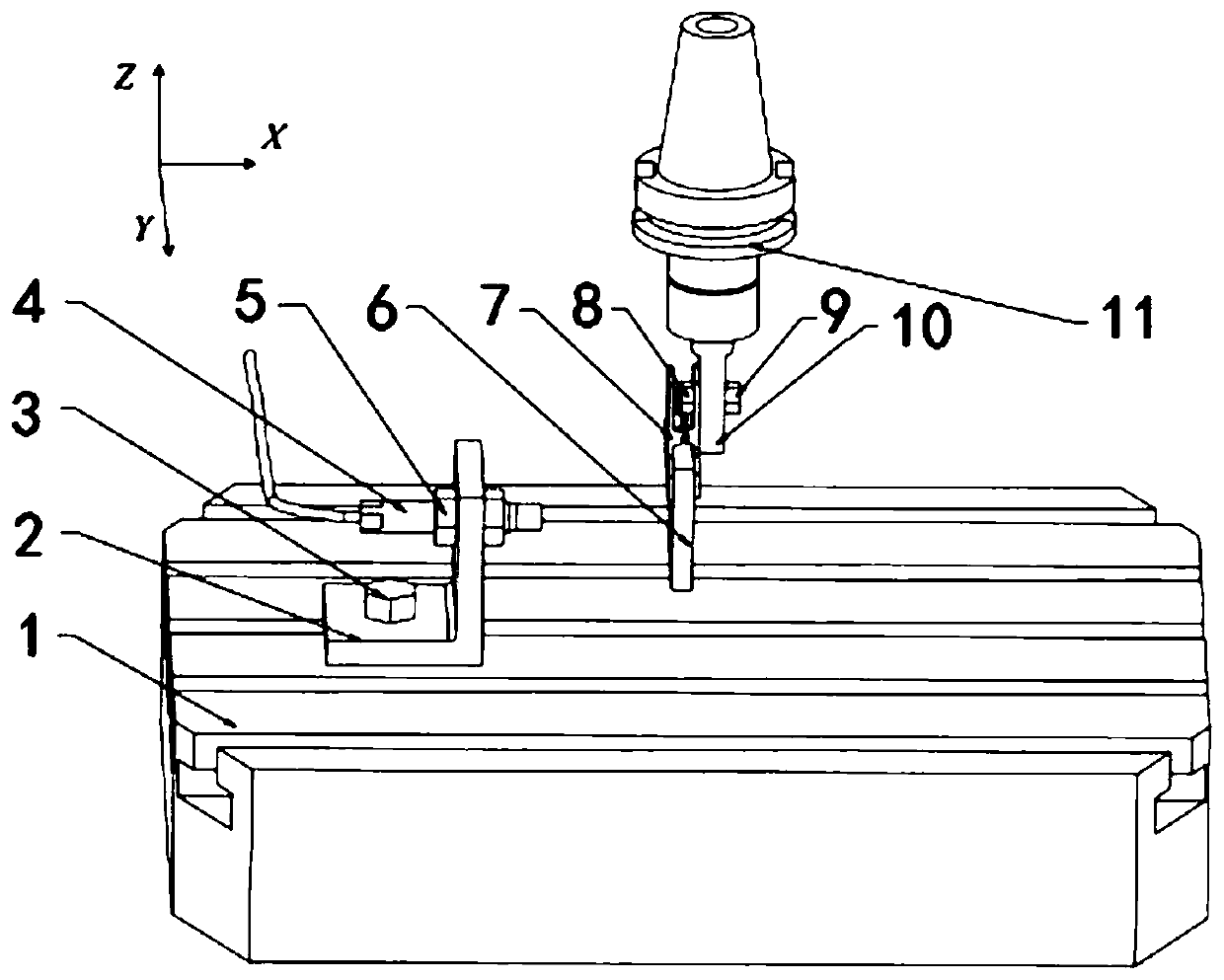

[0033] Such as figure 1, the invention discloses an eddy current sensor machine tool online calibration device installed on a machine tool, comprising an eddy current sensor 4, a sensor fixing device installed on a machine tool workbench 1 and a measured conductor fixing device installed on a machine tool spindle.

[0034] The sensor fixing device is composed of a machine tool table 1, a sensor bracket 2, a compression bolt 3, and a sensor probe fixing nut 5; the sensor bracket 2 is fixed on the machine tool table 1 through the compression bolt 3, and the eddy current sensor 4 is fixed through the sensor probe fixing nut 5 is fixed on the senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com