Bottom mud squeezing comprehensive treatment system

A comprehensive treatment and sludge treatment technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as high cost, improve treatment effect and reduce treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

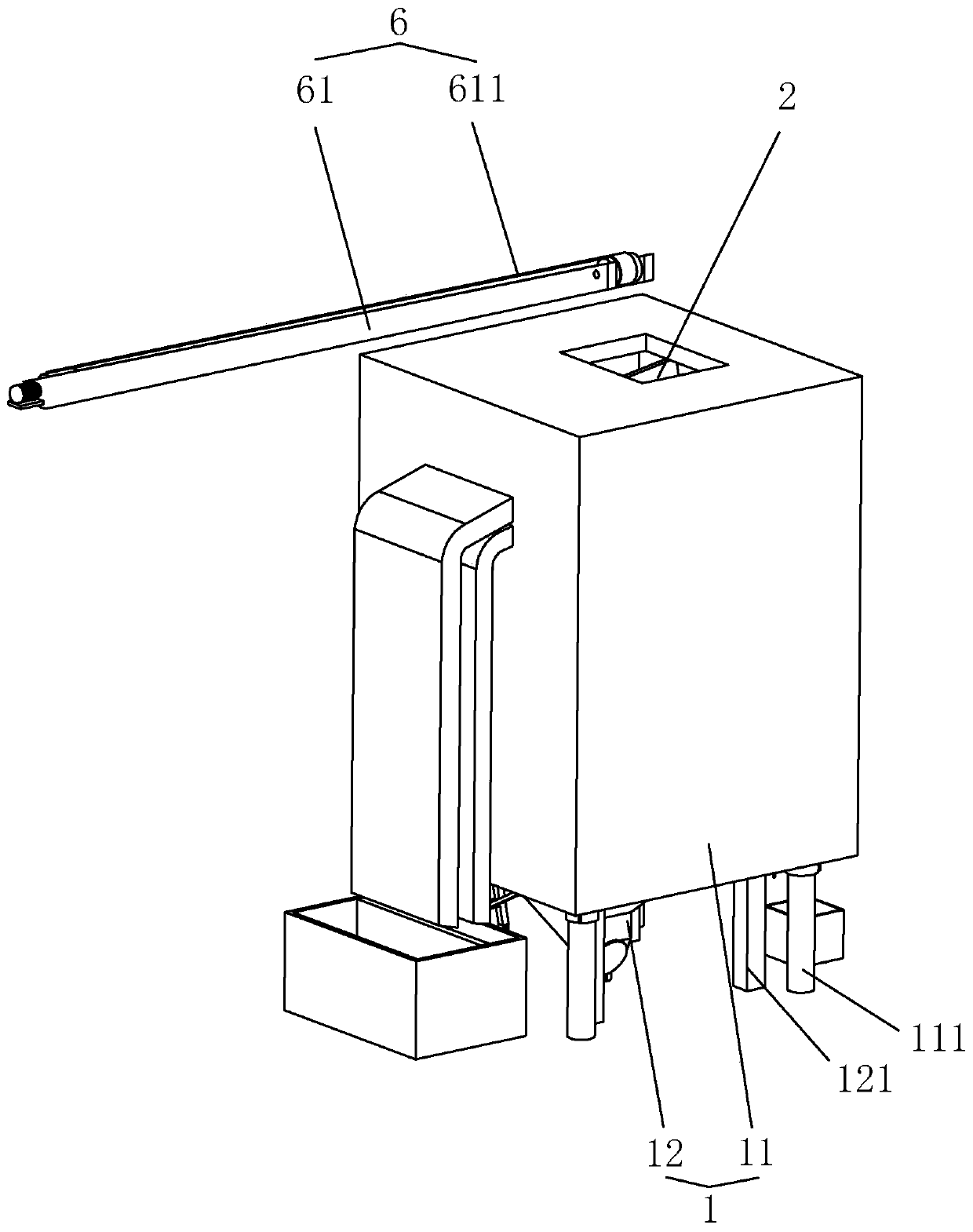

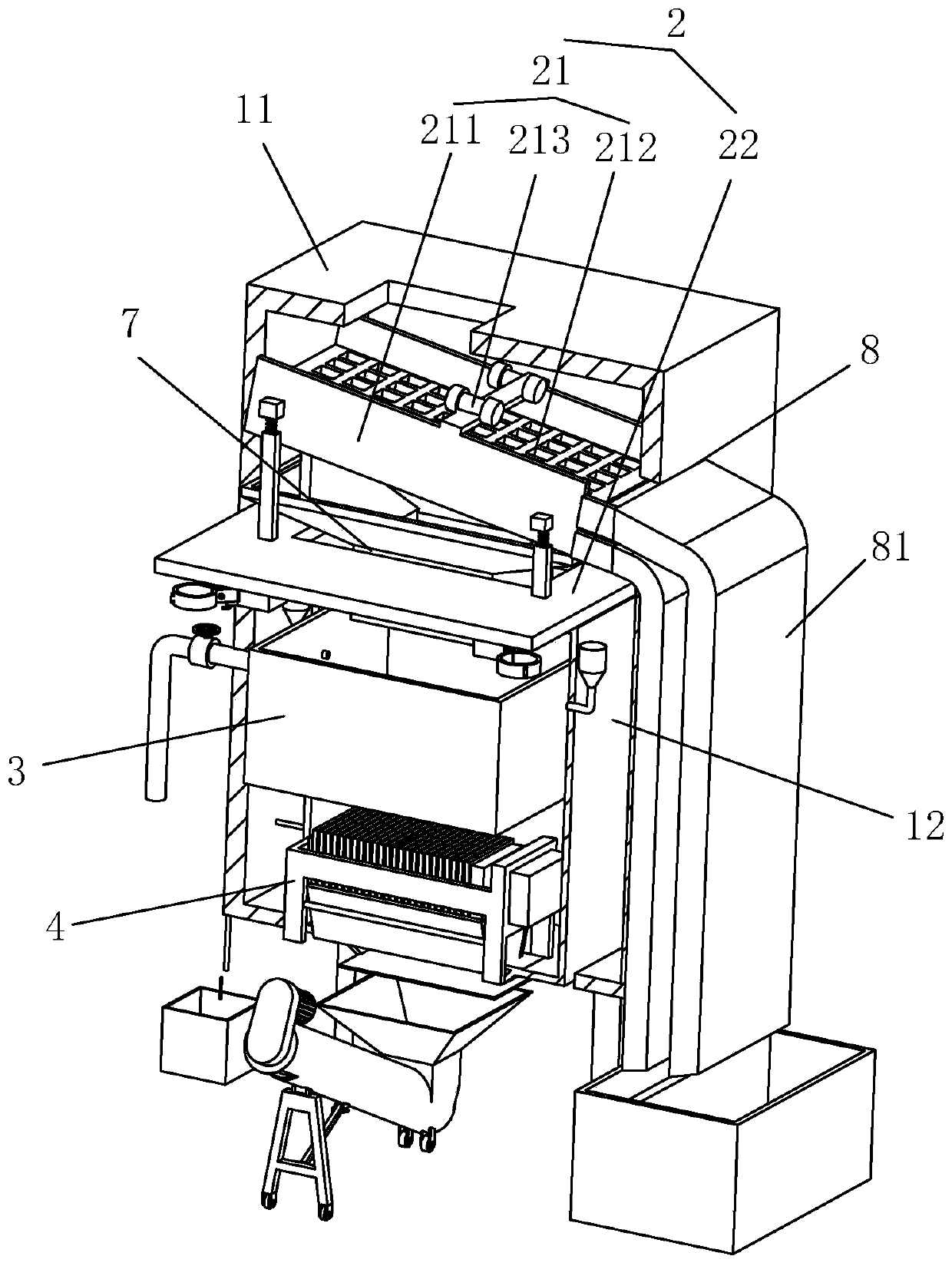

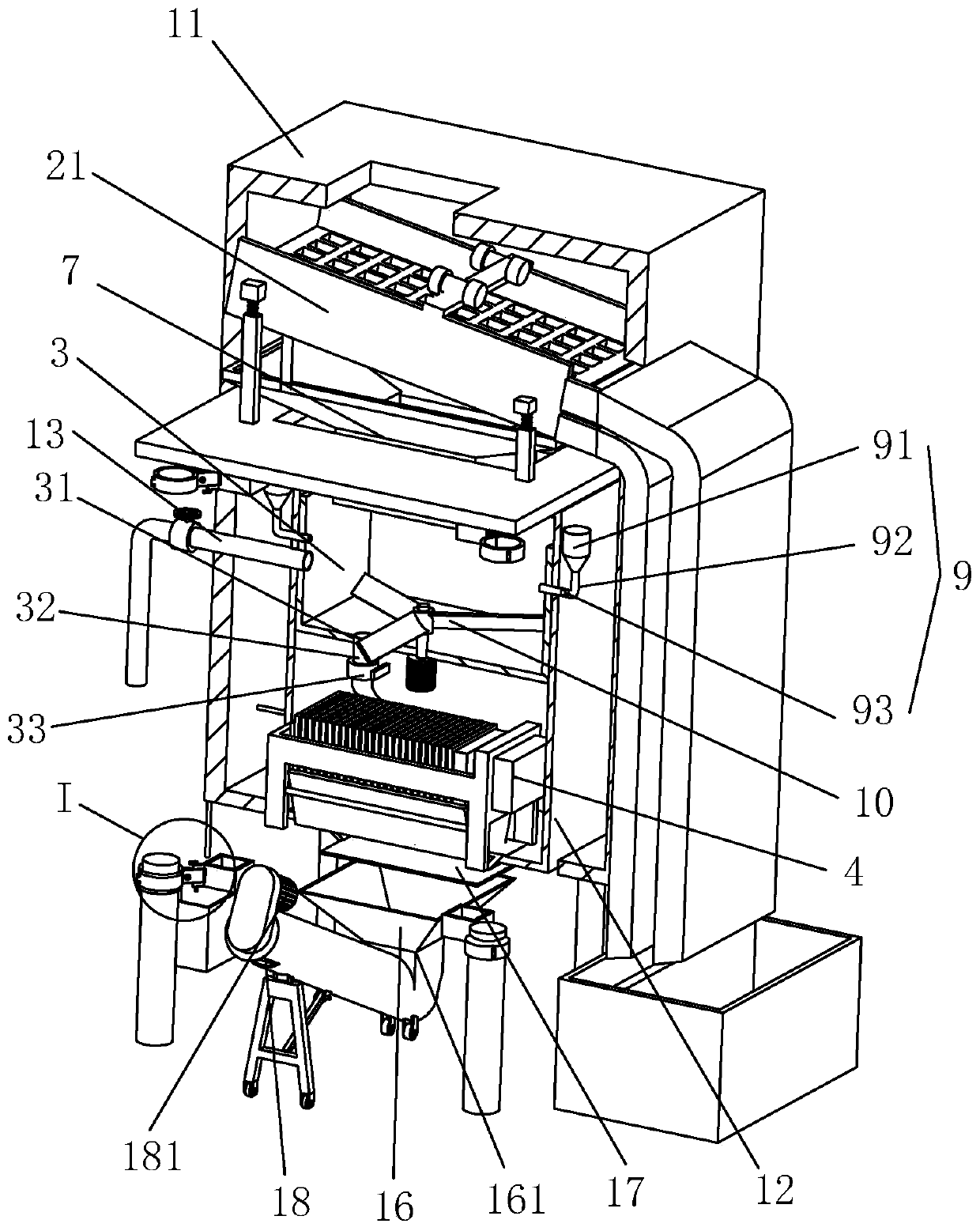

[0033] A comprehensive treatment system for bottom sludge pressing, referring to figure 1 As shown, the processing body 1 is included, the processing body 1 includes a vertical shell 11 with an upper opening, a sand and gravel separation device 2 is arranged on the upper end of the shell 11, and a vertical and independent base 12 is arranged inside the shell 11 , combined with figure 2 As shown, the base 12 is sequentially provided with a sludge treatment tank 3 connected to the sand and gravel separation device 2 and a plate and frame filter press 4 connected to the sludge treatment tank 3 from top to bottom, and a transmission device is provided on the outer wall of the shell 11 6. Relying on the conveying device 6, the sediment at the bottom of the river can be sent in from the upper opening of the casing 11, so as to process the sediment.

[0034] refer to figure 2As shown, the sand and gravel separation device 2 includes a placement plate 22 connected to the upper end...

Embodiment 2

[0041] A bottom sludge pressing comprehensive treatment system, the difference from Embodiment 1 is that in combination with Figure 5 and Figure 6 As shown, the processing main body 1 is provided with multiple groups side by side, and the conveying device 6 also includes a horizontal feeding conveyor 62, and a horizontal feeding belt 621 circulates on the feeding conveyor 62, and the upper end of the feeding conveyor 61 is located at the feeding conveyor 62. Above one end of the belt 621, a material distribution conveyor 63 is slidably connected to the feed conveyor 62 along its length direction. The material distribution conveyor 63 includes a material distribution frame 631 whose length direction is perpendicular to the length direction of the feed conveyor frame. The distribution frame 631 is horizontally mounted above the feeding conveyor 62 . Each of the two ends in the length direction of the distribution frame 631 is connected with a distribution transmission roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com