Environment-friendly biological stable cutting fluid and preparation method thereof

A bio-stabilized cutting fluid technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of semi-synthetic cutting fluid system instability, stratification, solidification, etc., achieve long operation and storage time, reduce production cost and storage time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

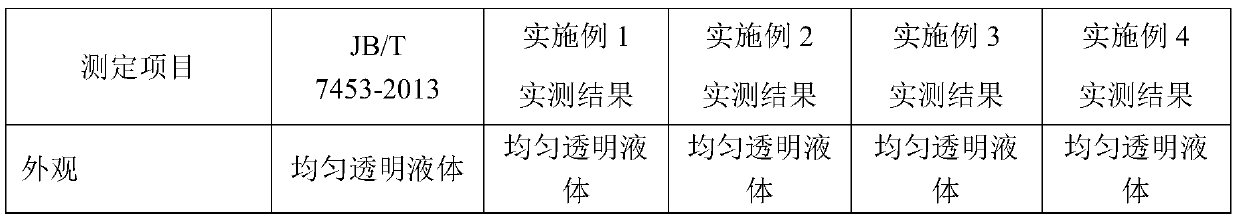

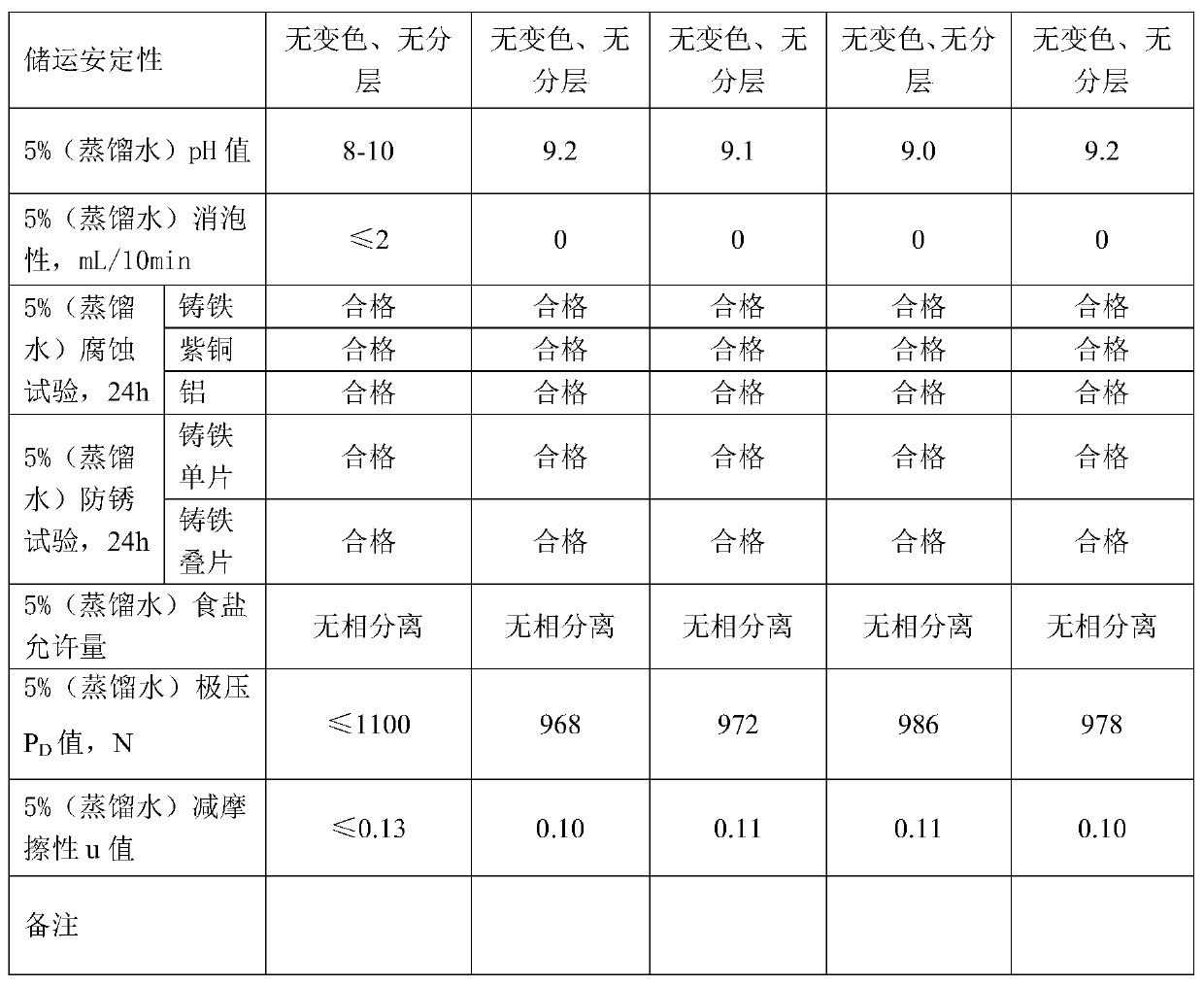

Embodiment 1

[0033] The invention provides an environment-friendly biostable cutting fluid, which consists of PAG base oil, lubricant, extreme pressure agent, emulsifier, coupling agent, anti-fogging agent, water, rust inhibitor, alkali reserve regulator, bactericide and Defoamer composition. First put the PAG base oil into the reaction kettle according to the weight ratio, then add lubricant A, lubricant B, lubricant C, extreme pressure agent A, extreme pressure agent B, and extreme pressure agent C in sequence under the condition of stirring at room temperature , emulsifier A, emulsifier B, couplant A, couplant B, anti-fogging agent, bactericide and defoamer, the order of addition cannot be changed, and the oily part can be obtained after stirring for 30 minutes; the PAG base oil mentioned in it The weight percentage in the cutting fluid is 42%, the weight percentage of the lubricant A in the cutting fluid is 2%, the weight percentage of the lubricant B in the cutting fluid is 2%, and th...

Embodiment 2

[0045] The invention provides an environment-friendly biostable cutting fluid, which consists of PAG base oil, lubricant, extreme pressure agent, emulsifier, coupling agent, anti-fogging agent, water, rust inhibitor, alkali reserve regulator, bactericide and Defoamer composition. First put the PAG base oil into the reaction kettle according to the weight ratio, then add lubricant A, lubricant B, extreme pressure agent A, extreme pressure agent B, emulsifier A, coupling agent A, Anti-fogging agent, bactericide and defoamer, the order of addition cannot be changed, and the oily part can be obtained after stirring for 30 minutes; wherein the weight percentage of the PAG base oil in the cutting fluid is 44%, and the lubricant A The weight percentage in the cutting fluid is 5%, the weight percentage of the lubricant B in the cutting fluid is 5%, the weight percentage of the extreme pressure agent A in the cutting fluid is 5%, and the extreme pressure agent A is 5% in the cutting fl...

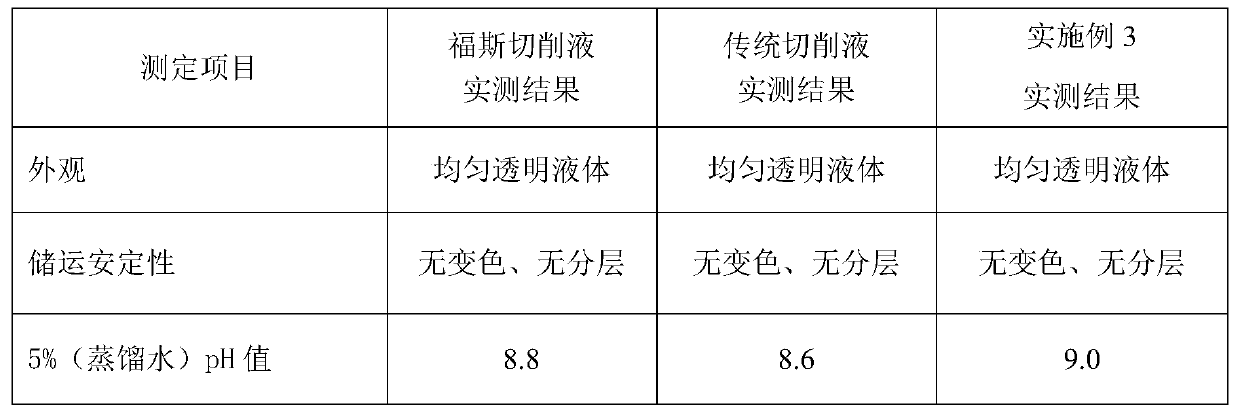

Embodiment 3

[0057] The invention provides an environment-friendly biostable cutting fluid, which consists of PAG base oil, lubricant, extreme pressure agent, emulsifier, coupling agent, anti-fogging agent, water, rust inhibitor, alkali reserve regulator, bactericide and Defoamer composition. First put the PAG base oil into the reaction kettle according to the weight ratio, and then add lubricant A, lubricant C, extreme pressure agent A, extreme pressure agent C, emulsifier B, and coupling agent B in sequence under the condition of stirring at room temperature, Anti-fogging agent, bactericide and defoamer, the order of addition cannot be changed, and the oily part can be obtained after stirring for 30 minutes; wherein the weight percentage of the PAG base oil in the cutting fluid is 50%, and the lubricant A The percentage by weight in the cutting fluid is 2%, the percentage by weight of the lubricant C in the cutting fluid is 3%, the percentage by weight of the extreme pressure agent A in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com