Heat exchanger structure having functions of dust removal and liquid separation

A heat exchanger, functional technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of many leakage points, increase the number of equipment and investment, long process, etc., and achieve strong practicability. , easy operation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

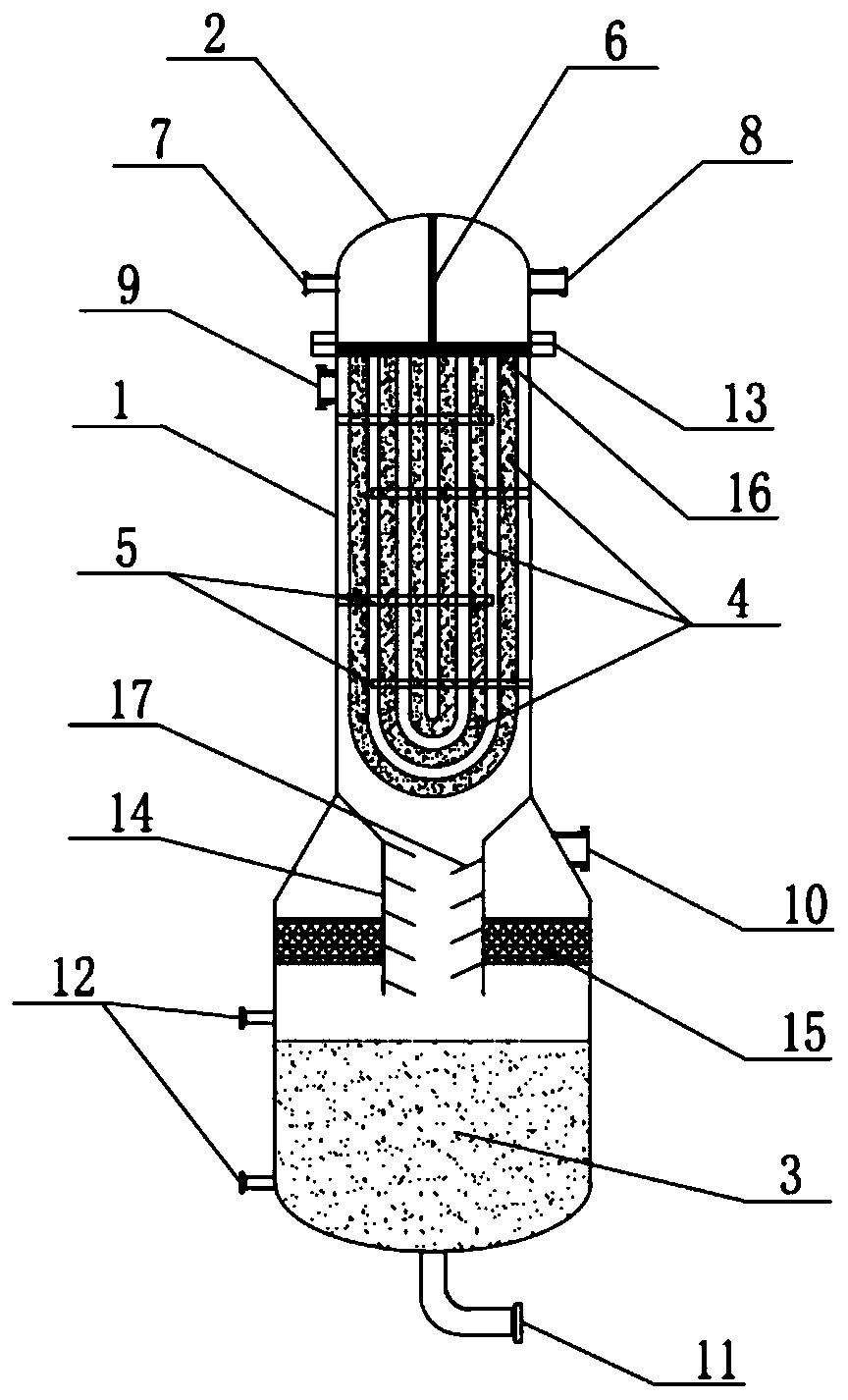

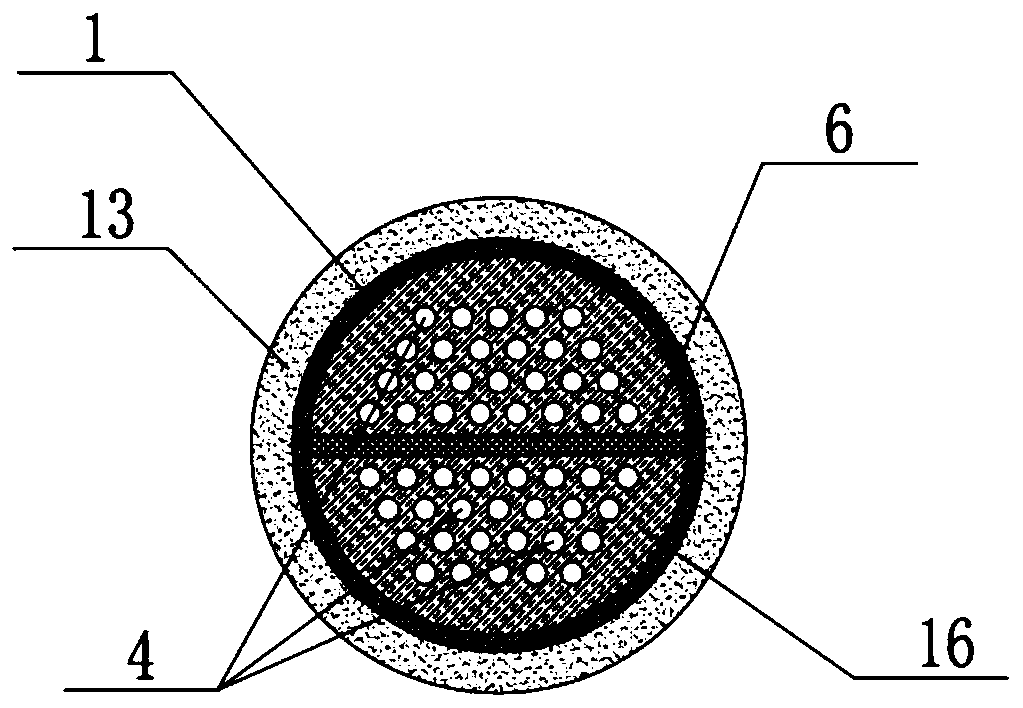

[0021] refer to figure 1 and figure 2 , the structure of the heat exchanger with dust removal and liquid separation functions according to the present invention includes a heat exchanger head 2, a heat exchanger shell 1, a partition plate 6, a Y-shaped diversion downcomer 14 and a liquid collection tank 3 ; The heat exchanger head 2 is fixed at the top opening of the heat exchanger shell 1, and the internal space of the heat exchanger head 2 is divided into a cold medium inlet space and a cold medium outlet space through a split partition plate 6, and the heat exchange A cold medium outlet 8 and a cold medium inlet 7 are arranged on the cover head 2, wherein the cold medium outlet 8 communicates with the cold medium outlet space, the cold medium inlet 7 communicates with the cold medium inlet space, and the inside of the heat exchanger shell 1 A U-shaped heat exchan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap