Air temperature vaporizer free from frosting and freezing

A vaporizer, air temperature technology, applied in indirect heat exchangers, tubular elements, heat exchange equipment, etc., can solve the problem that the output gas temperature cannot be guaranteed to meet the equipment requirements, the gas temperature at the outlet cannot be controlled in real time, and the space displacement design is used. Restrictions and other issues, to achieve the effect of being conducive to popularization and use, simple structure, and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

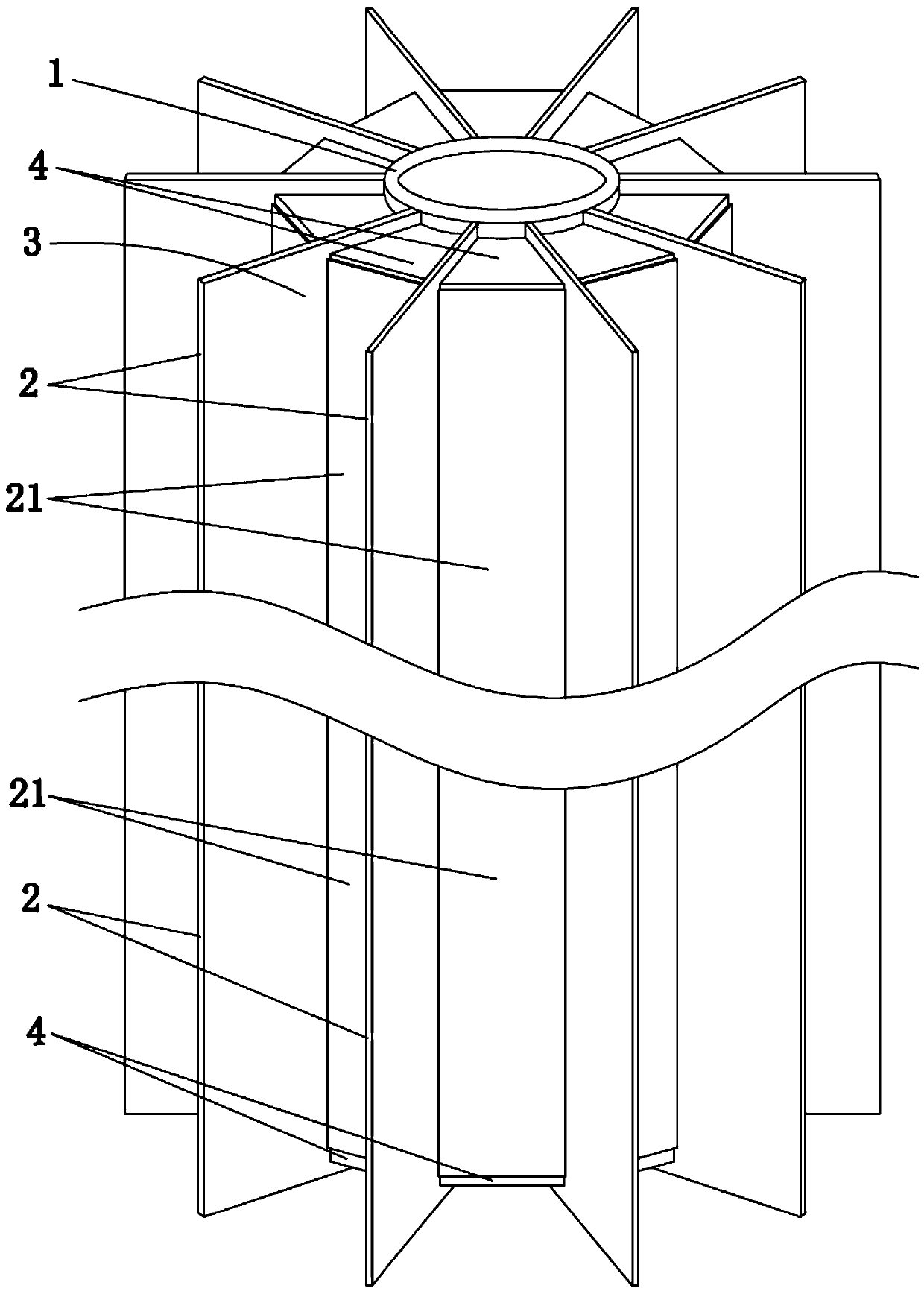

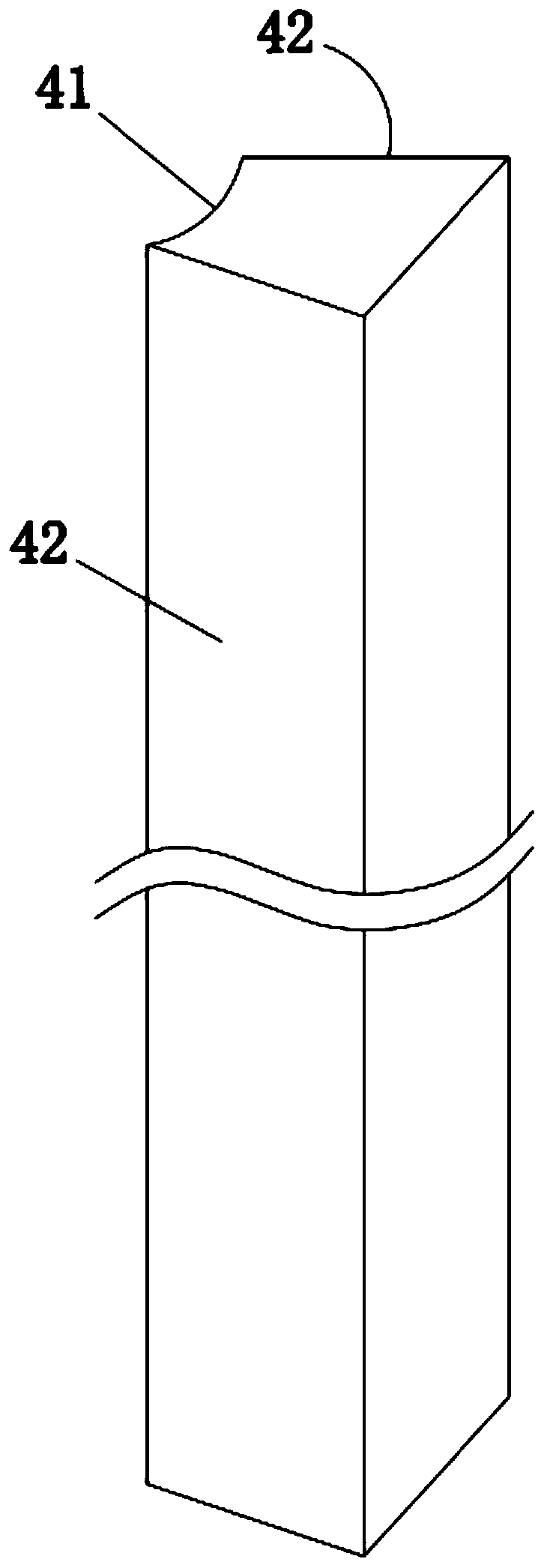

[0028] Such as Figure 1 to Figure 3 As shown in , the non-frosting and non-icing air-temperature evaporator described in Embodiment 1 of the present invention includes a heat exchange tube 1, and the peripheral surface of the heat exchange tube 1 is provided with several ring-shaped intervals axially arranged heat exchange fins 2, and a heat exchange channel 3 is formed between two adjacent heat exchange fins 2; the heat exchange channel 3 is provided with an electric heating assembly 4, and the electric heating assembly 4 is connected with the two heat exchange fins The surface of the sheet 2 and the heat exchange tube 1 is connected and fixed, and the specific structure can be: the electric heating element 4 is a Teflon heating element or a silicone rubber heating element, and the Teflon heating element or the silicon rubber heating element is columnar, Its inner surface 41 and left and right side surfaces 42 are respectively connected and fixed with the outer surface of th...

Embodiment 3

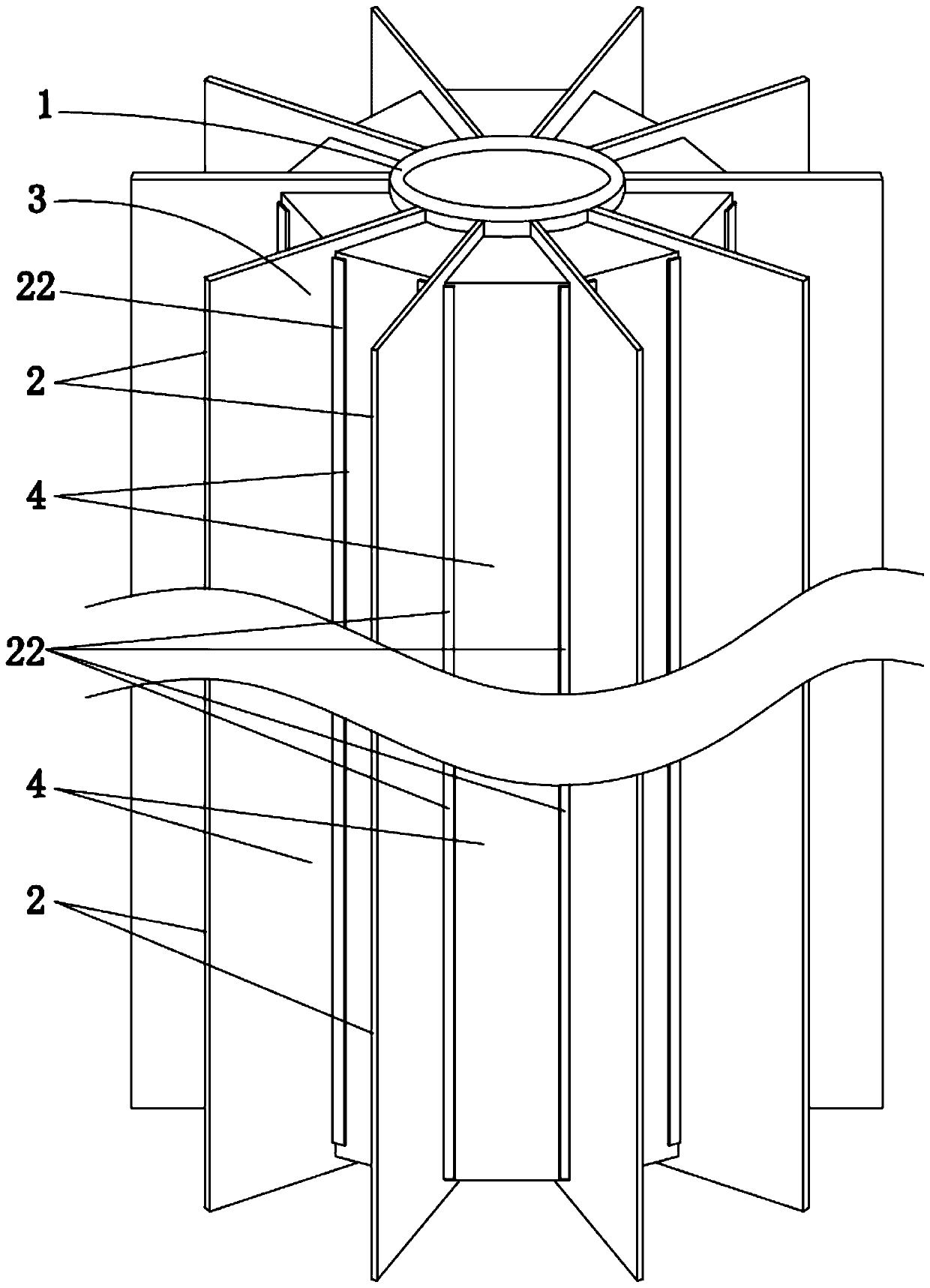

[0033] Such as Figure 4 and Figure 5 As shown in , the non-frosting and non-icing air-temperature evaporator described in the second embodiment of the present invention has basically the same structure as the first embodiment, including the heat exchange tube 1, and the peripheral surface of the heat exchange tube 1 A plurality of heat exchange fins 2 arranged axially at intervals in a ring are provided, and a heat exchange channel 3 is formed between two adjacent heat exchange fins 2 , and an electric heating assembly 4 is arranged in the heat exchange channel 3 . The only difference is that the electric heating assembly 4 includes an electric heating element 43 and an insulating and heat-conducting outer layer 44 covering the electric heating element 43 , and the insulating and heat-conducting outer layer 44 is closely attached to the side of the heat exchange fin 2 On the surface, each heat exchanging fin 2 is provided with an electric heating assembly 4; for example: an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com