Oil leakage defect detection method and system

A defect detection and oil leakage technology, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, image data processing, etc., can solve the problem of high requirements for image acquisition equipment, false alarms, detection The results lack stability and other problems, to achieve the effect of guaranteeing the test results and eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

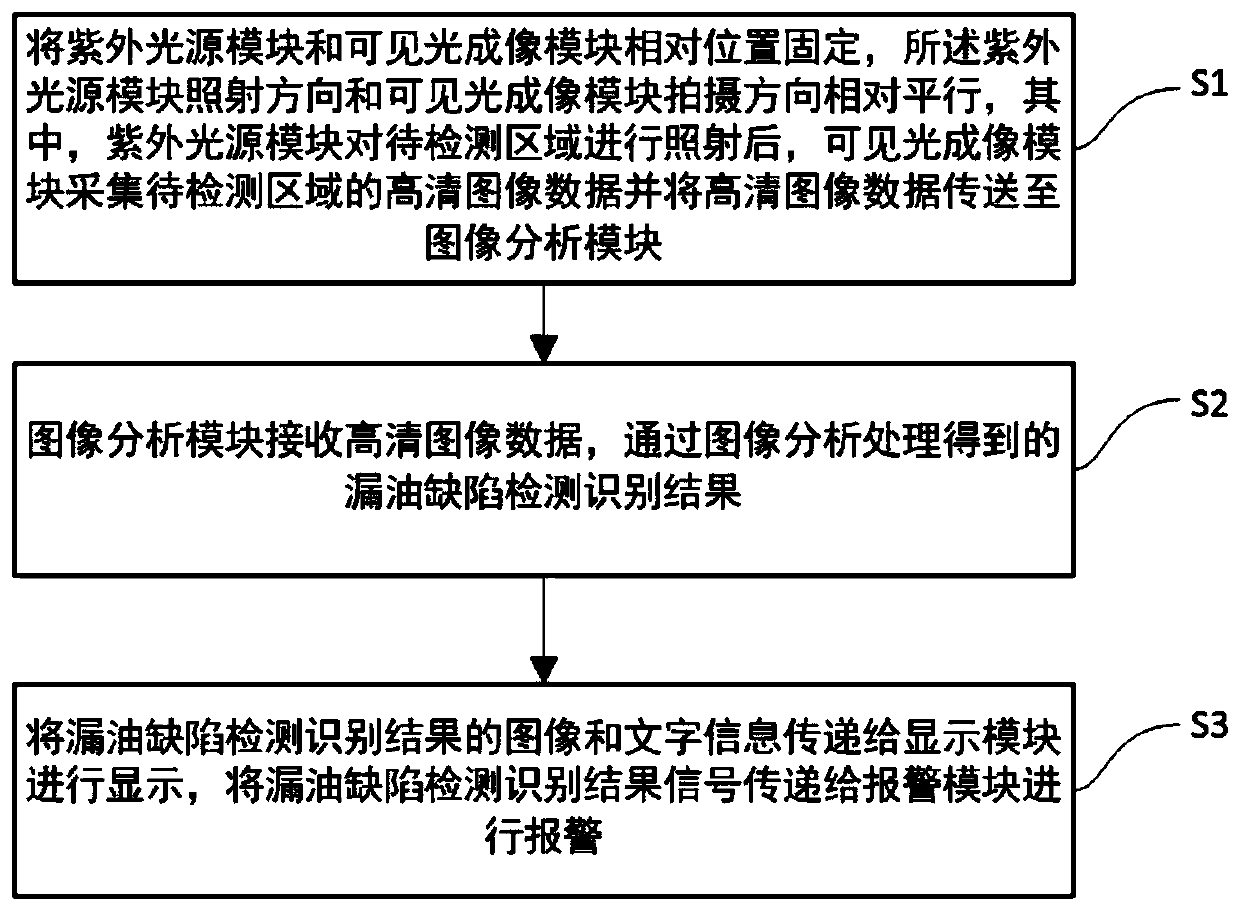

[0077] This embodiment provides a method for detecting oil leakage defects, such as figure 1 , including the following steps:

[0078] S1: Fix the relative position of the ultraviolet light source module and the visible light imaging module. The irradiation direction of the ultraviolet light source and the shooting direction of the high-definition camera are both facing the area to be detected, and the two directions are relatively parallel. Wherein, use the parameter setting module to set the parameters of the visible light imaging module After setting, after the ultraviolet light source module irradiates the area to be detected, the visible light imaging module collects high-definition image data of the area to be detected and transmits the high-definition image data to the image analysis module;

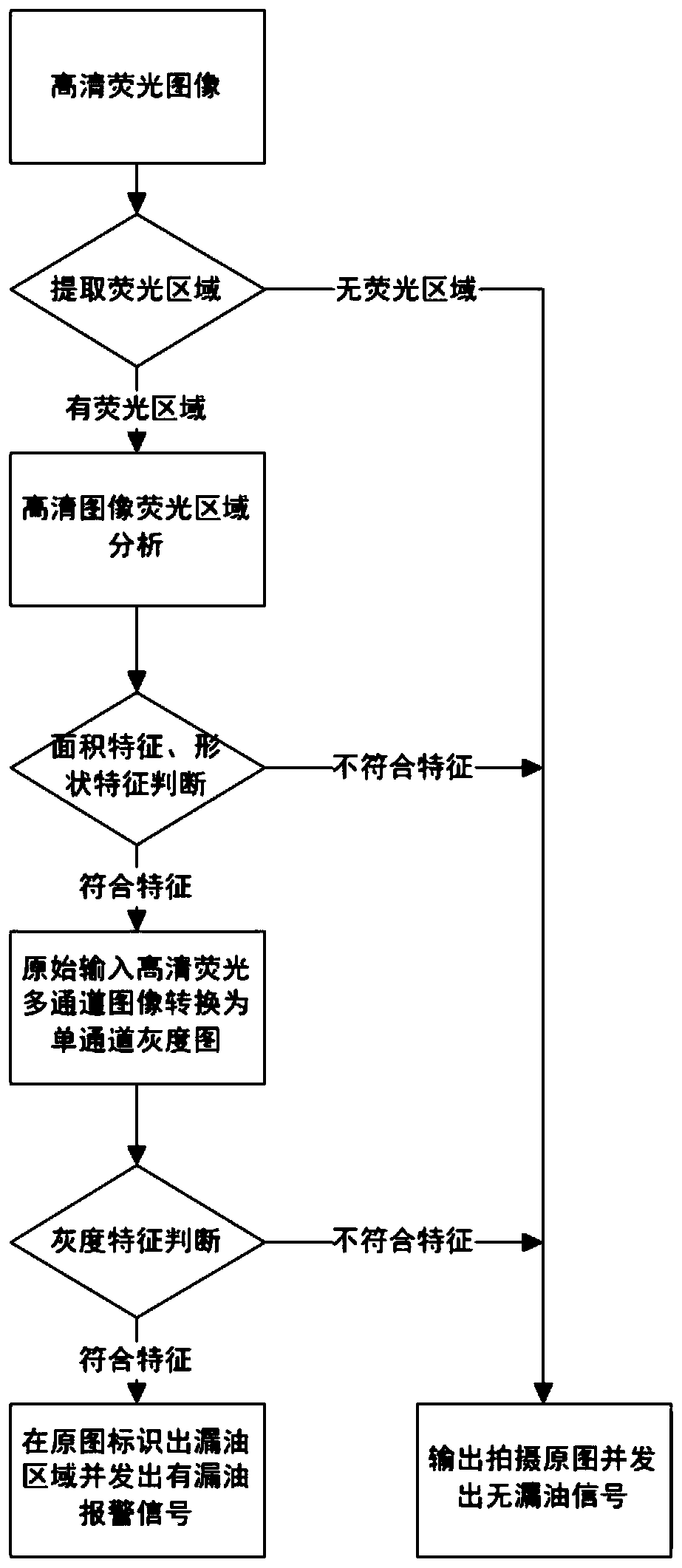

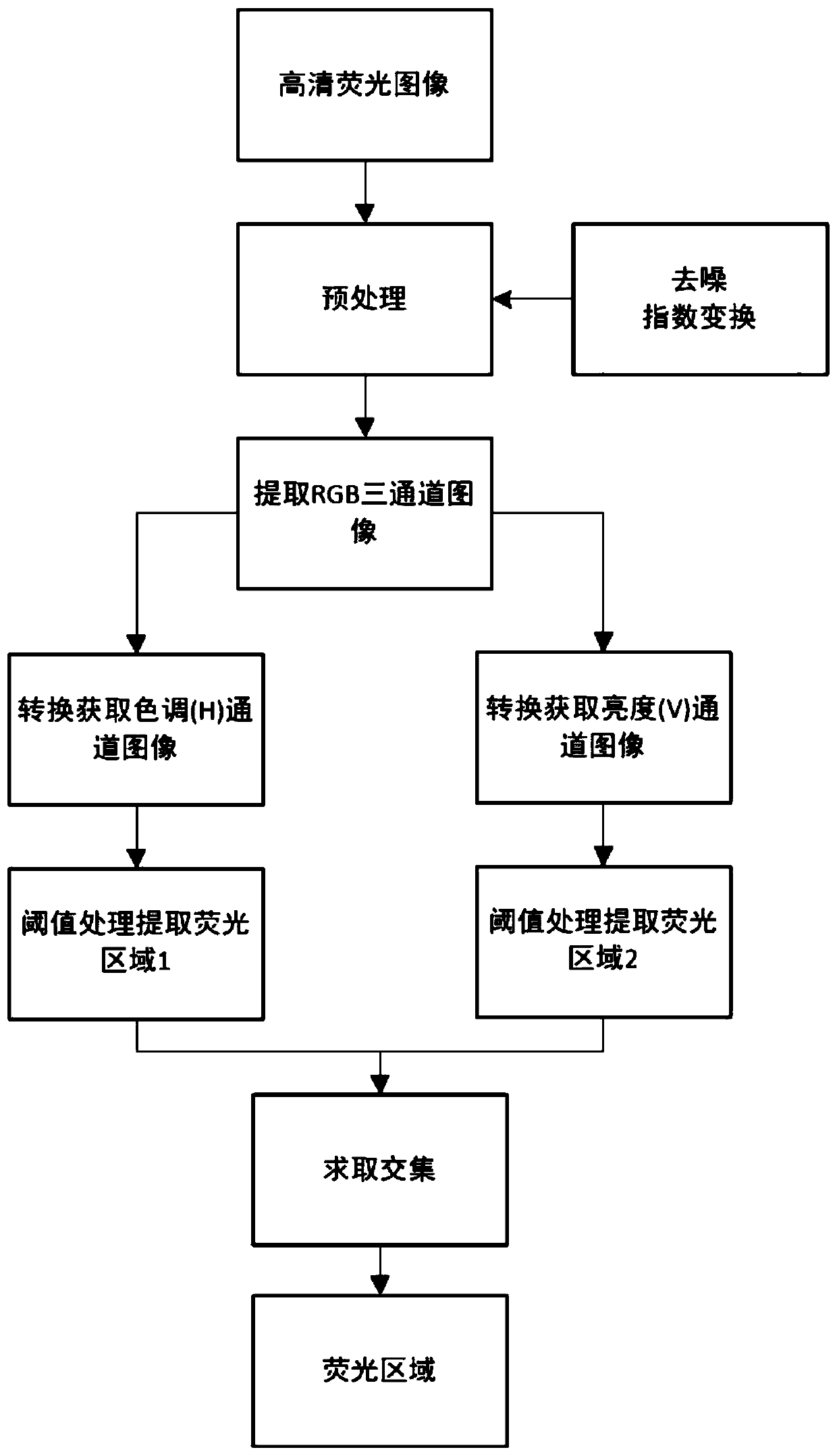

[0079] S2: The image analysis module receives high-definition image data, and obtains the detection and recognition results of oil leakage defects through image analysis and proce...

Embodiment 2

[0121] This embodiment provides an oil leakage defect detection and identification system, such as Figure 4 , including image acquisition subsystem and information interaction subsystem;

[0122] The image acquisition subsystem includes an ultraviolet light source module and a visible light imaging module;

[0123] The information interaction subsystem includes a parameter setting module, a display module, an alarm module, and an image analysis module;

[0124] The ultraviolet light source module emits ultraviolet light to irradiate the area to be detected;

[0125] The visible light imaging module collects high-definition visible light images of the area to be detected, and transmits the high-definition image data to the image analysis module;

[0126] The parameter setting module is used for the user to set the parameters of the visible light imaging module, the result display setting, and the alarm information setting;

[0127] The display module performs image display ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com