Tea processing system and process based on accurate moisture control

A technology of processing system and processing technology, applied in the direction of control/regulation system, humidity control, non-electric variable control, etc., can solve the problem of not achieving accurate moisture control, achieve stable quality, reduce failure probability, and ensure stable management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

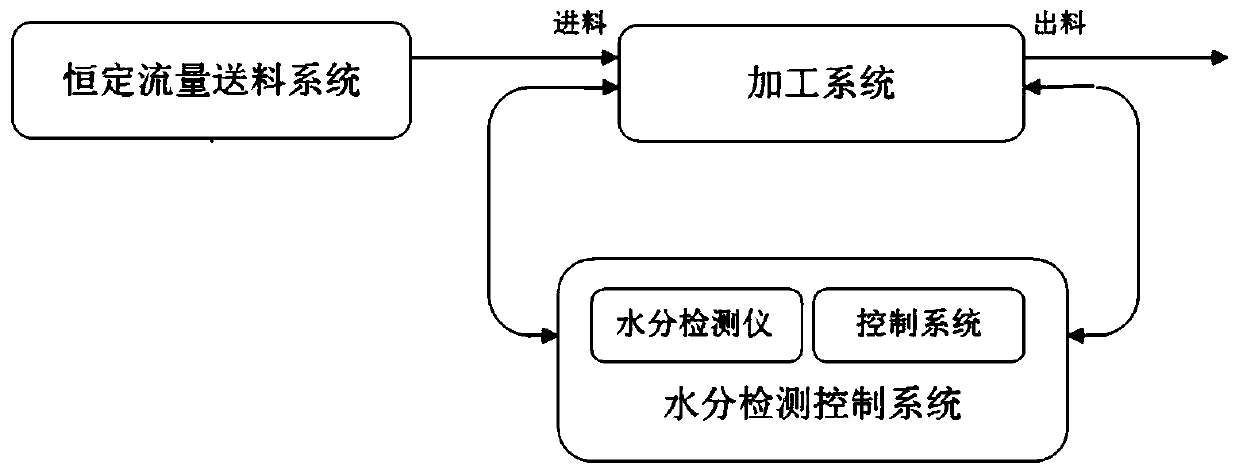

[0026] Embodiment 1: as figure 1As shown, a tea processing system based on precise moisture control includes a constant flow feeding system, a processing system, and a moisture detection and control system. The constant flow feeding system is used to adjust or control the feeding amount and transportation speed of materials and maintain the amount of incoming materials. Constant, the feeding amount can be achieved through the unified cooperation of temporary storage and lifting devices, metering tubes and dynamic electronic scales. The transportation speed is controlled by the conveying mechanism, such as the conveying drive motor of the conveyor belt. The processing conditions include the processing temperature value of the processing system, The processing parameters related to moisture control in the processing system, such as the heating power of the processing machine, etc., make the processing parameters tend to be stable. The moisture detection and control system can in...

Embodiment 2

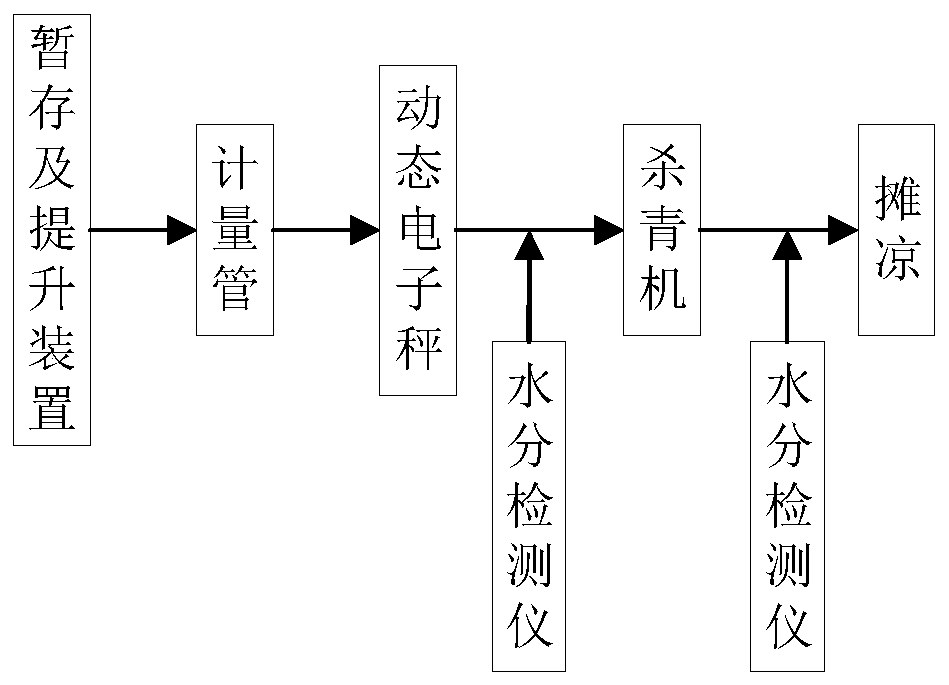

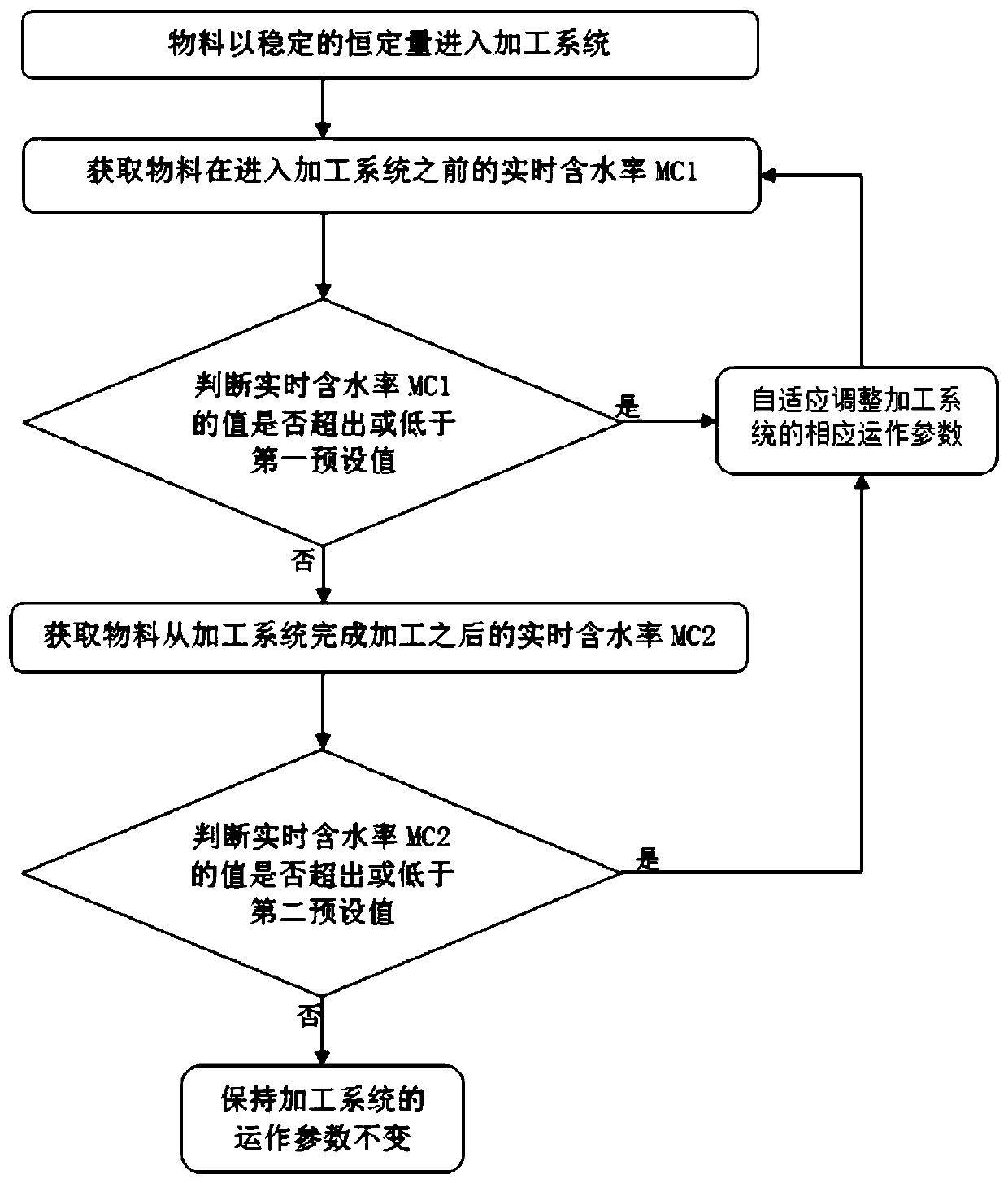

[0028] Embodiment 2: Take the finishing link as an example, such as figure 2 , image 3 As shown, a tea processing technology based on precise moisture control, when the material passes through the moisture detector on the conveyor belt before entering the greening system, the moisture detector obtains the real-time moisture content MC1 value of the material before entering the greening system and feeds it back to the controller ;When the material is discharged after finishing, when it passes through another group of moisture detectors, the moisture detector will obtain the real-time moisture content MC2 value of the material from the finishing system and feed it back to the controller; after the controller receives the MC1 value The intelligent algorithm judges whether the value of the real-time moisture content MC1 exceeds or is lower than the first preset value; after the controller receives the value of MC2, the intelligent algorithm judges whether the value of the real-t...

Embodiment 3

[0029] Embodiment 3: In actual use: a tea processing technology based on precise moisture control, which controls temporary storage and lifting devices, metering tubes, and belt conveyors by the controller to keep the incoming materials constant, and passes through the moisture detection signals before and after the processing machine. Then feed back to the processing machine and adjust the parameters of the processing equipment through the algorithm to ensure the stability and uniformity of moisture after processing. After the fresh leaves stand green, they pass through the temporary storage and lifting device, and are installed at the temporary storage and lifting device or at the exit of the conveyor. The photoelectric sensor sends out a signal to control the speed of the temporary storage and lifting device to lift the conveyor belt, and realize the automatic tea delivery flow. Control, there is a dynamic electronic scale under the metering tube, the material first falls fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com