Ultrasonic atomizing device

A technology of ultrasonic atomization and atomization chamber, which is applied in the field of medical equipment, can solve the problems of lack of reliable solutions and achieve the effects of maintaining efficient operation, controlling occurrence and development, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

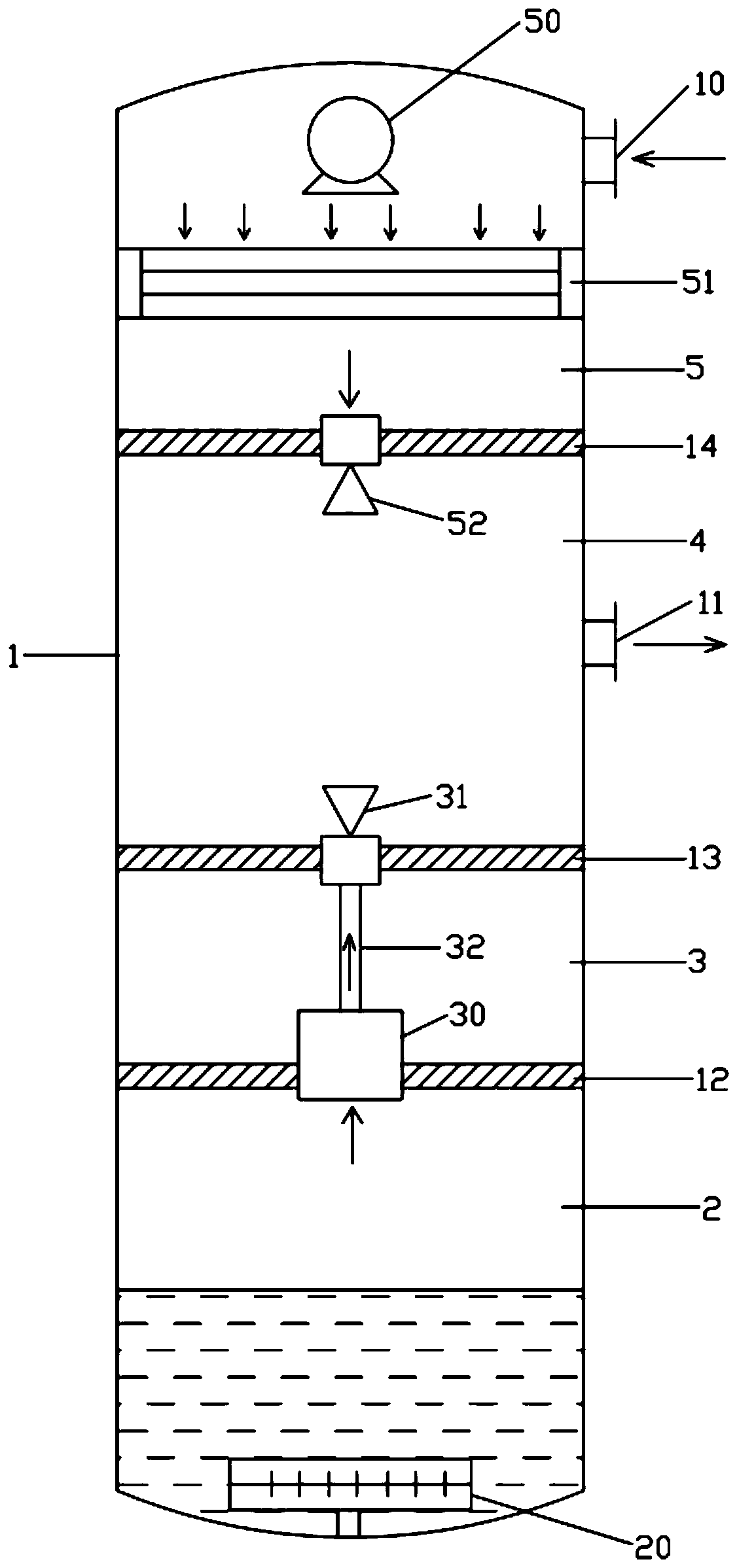

[0038] Such as figure 1 As shown, this embodiment provides an ultrasonic atomization device, including an atomization box 1, an atomization chamber 2, a mist removal chamber 3, a mixing chamber 4, and a heating chamber 5 arranged in the atomization box 1 in sequence from bottom to top, The ultrasonic transducer 20 arranged in the atomization chamber 2, the air pump 30 arranged in the mist removal chamber 3, the mist removal nozzle 31 connected with the air pump 30, the fan 50 and the heater 51 arranged in the heating chamber 5 and the The hot blast in the heating chamber 5 is discharged into the exhaust nozzle 52 in the mixing chamber 4;

[0039] The heating chamber 5 is provided with an air inlet 10, and the mixing chamber 4 is provided with an air outlet 11;

[0040] The atomizing chamber 2 communicates with the mixing chamber 4 through an air pump 30 and a mist discharge spray head 31 , so as to deliver the mist generated in the atomizing chamber 2 to the mixing chamber 4 ...

Embodiment 2

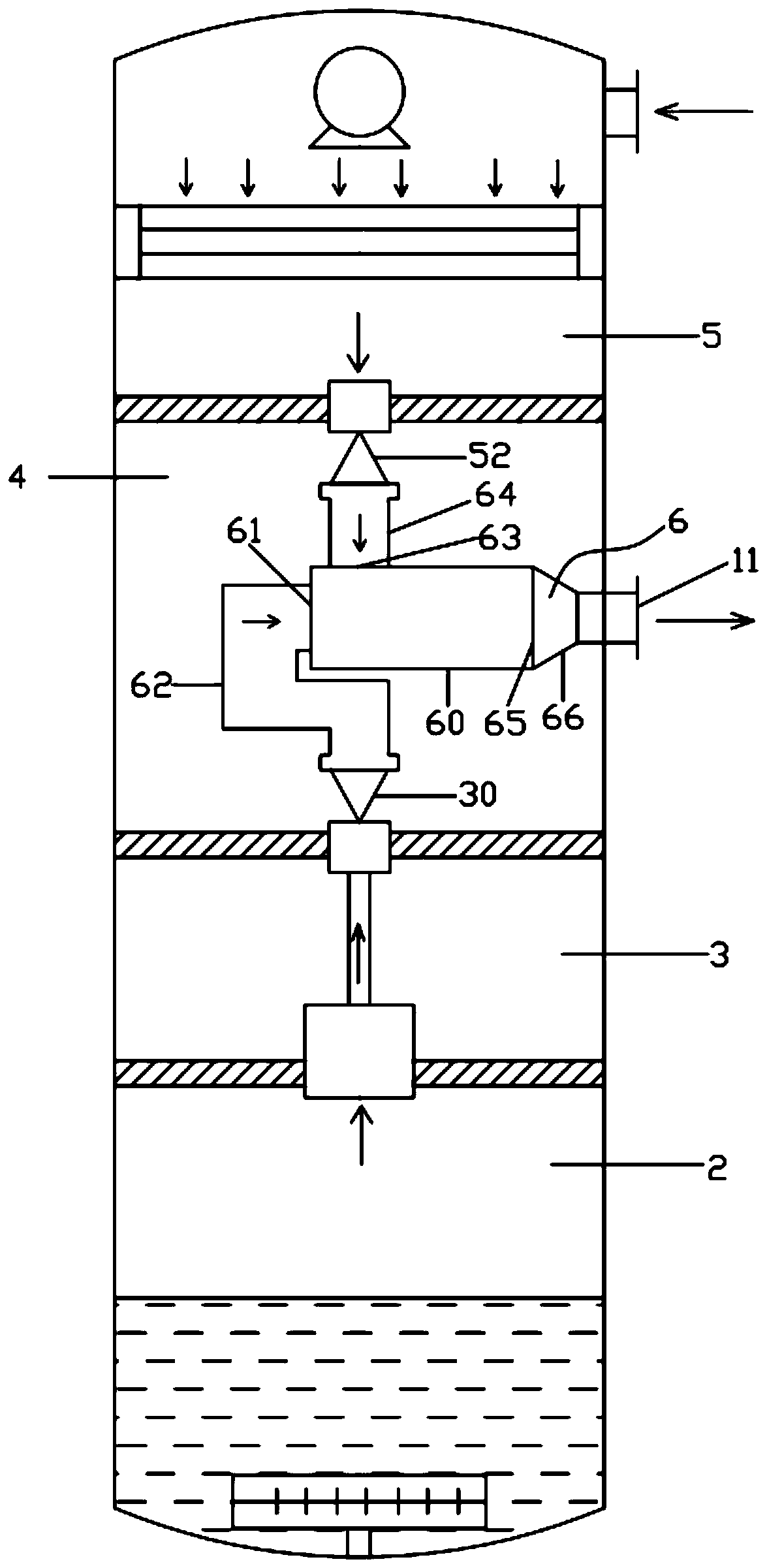

[0050] refer to figure 2 , On the basis of Embodiment 1, further, a diversion mixing assembly 6 is also provided in the mixing chamber 4, and the diversion mixing assembly 6 includes a column guide tube 60, which connects the mist discharge nozzle 31 to the column guide tube The first air inlet pipe 62 of the first air inlet 61 of 60, the second air inlet pipe 64 of the second air inlet 63 connecting the exhaust nozzle 52 to the column air guide pipe 60, and the second air inlet pipe 64 of the column air guide pipe 60 The air outlet 65 is connected to the exhaust pipe 66 of the air outlet 11; the first air inlet 61 is arranged along the axial direction of the column guide tube 60, and the second air inlet 63 is tangentially arranged along the outer peripheral wall of the column guide tube 60 It is provided that the second air inlet 63 is perpendicular to the air inlet direction of the first air inlet 61 .

[0051] The mist enters the column guide tube 60 axially through the ...

Embodiment 3

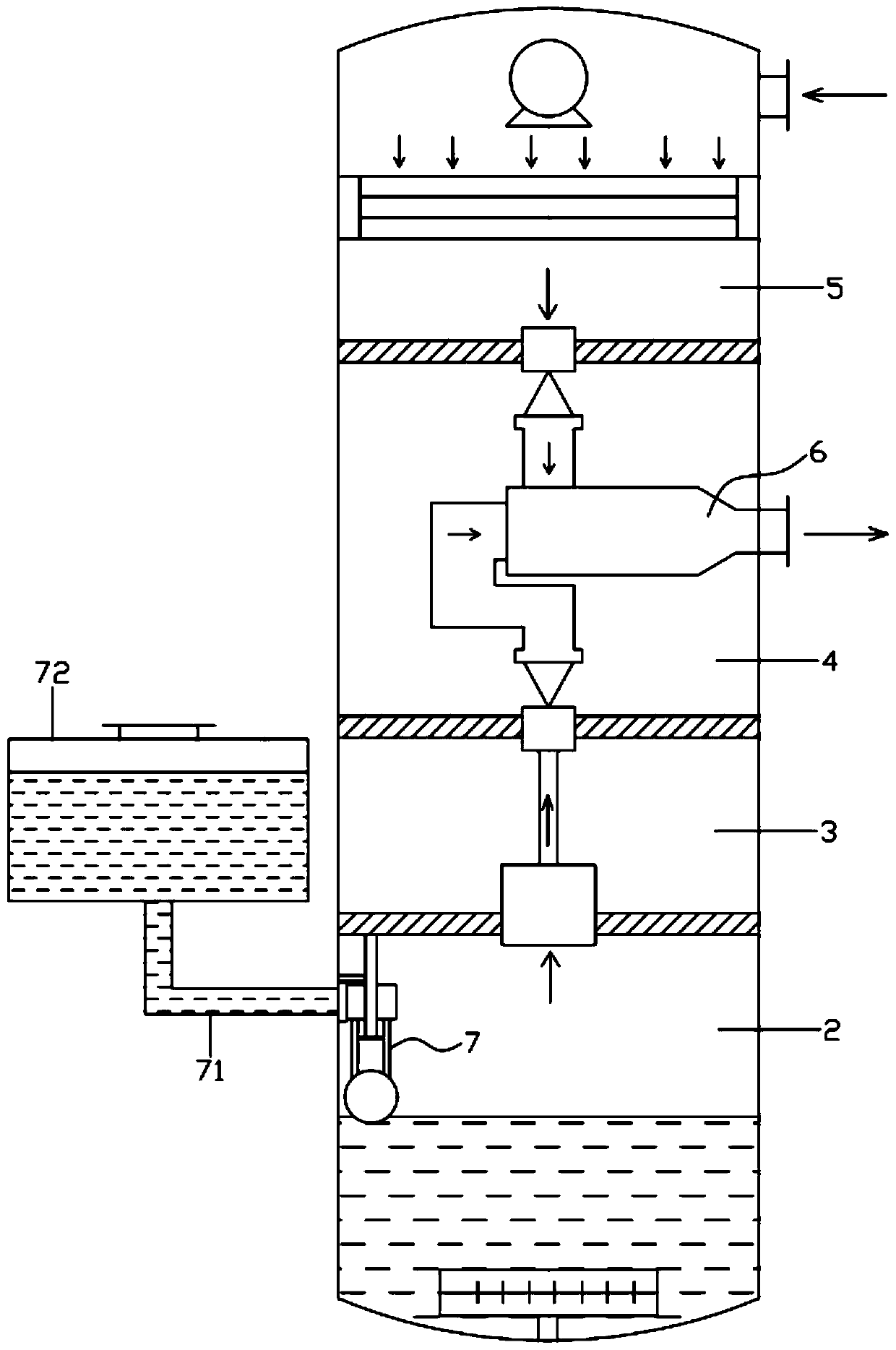

[0053] refer to Figure 3-5 , On the basis of Embodiment 1 or 2, further, the ultrasonic atomization device further includes an automatic liquid replenishment assembly 7, and the automatic liquid replenishment assembly 7 includes a liquid replenishment port 70 arranged on the side of the atomization chamber 2, through which the liquid replenishment pipe 71 and the liquid replenishment The liquid storage tank 72 connected to the port 70, the guide rod 73 fixed on the bottom of the first partition 12, the sealing plug 74 that can slide vertically on the guide rod 73, and the sealing plug 74 fixed on the side of the sealing plug 74 The sealing rubber sheet 75 used to seal the liquid replenishing port 70 and the floating ball 76 fixed to the lower part of the sealing plug 74 through a connecting rod.

[0054] A limit rod 77 is connected between the inner wall of the atomization chamber 2 above the liquid replenishment port 70 and the guide rod 73;

[0055] The middle part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com