Fused magnesite melting lump cleaning unshelling device and use method

A technology for fused magnesia and fused lumps, applied in cleaning methods and utensils, chemical instruments and methods, and smoke removal, etc., can solve the problems of unsatisfactory dust control effect, pollution of external ecological environment, and failure to meet environmental protection requirements, etc. To achieve the effect of easy implementation, good dust removal efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

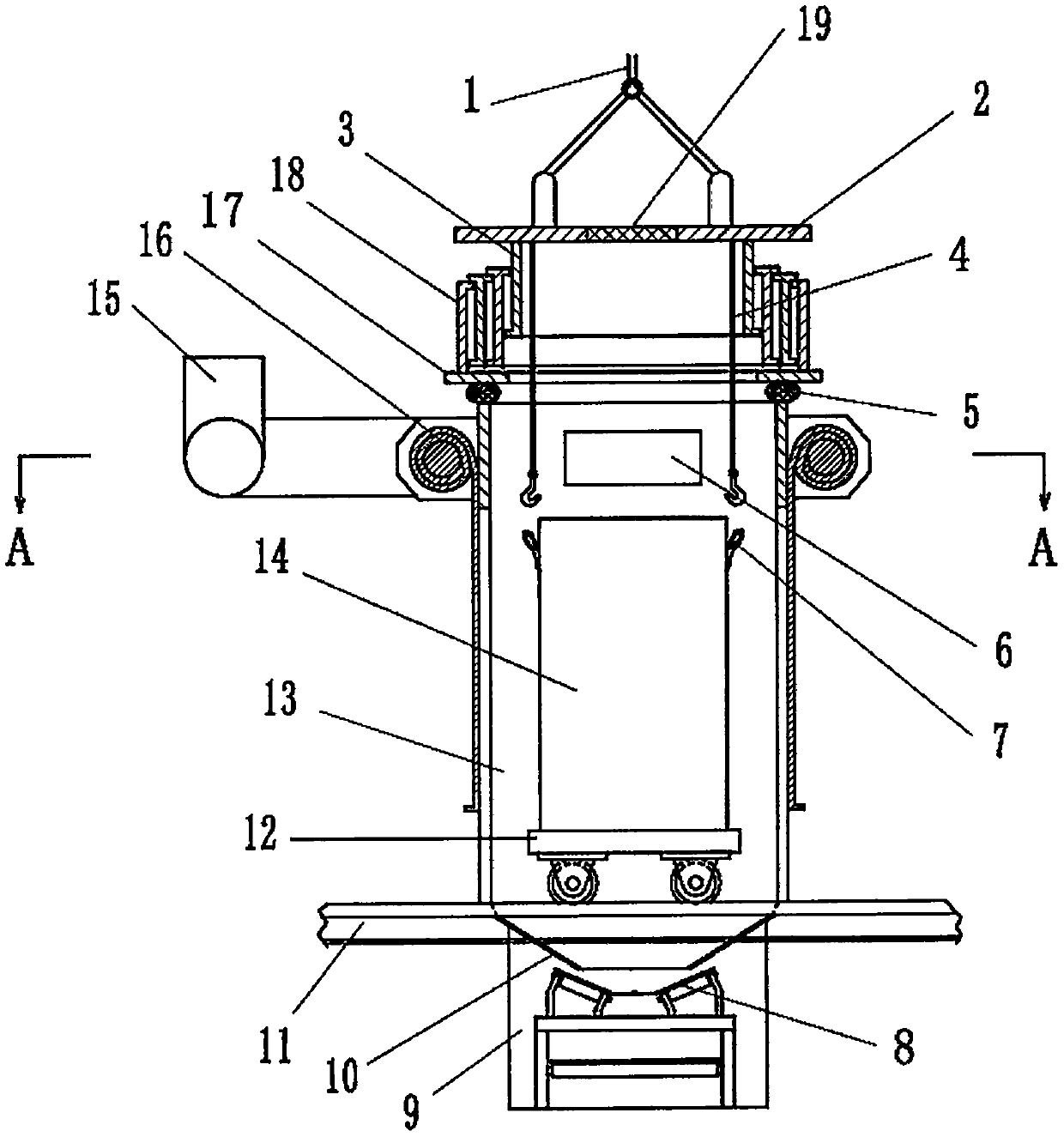

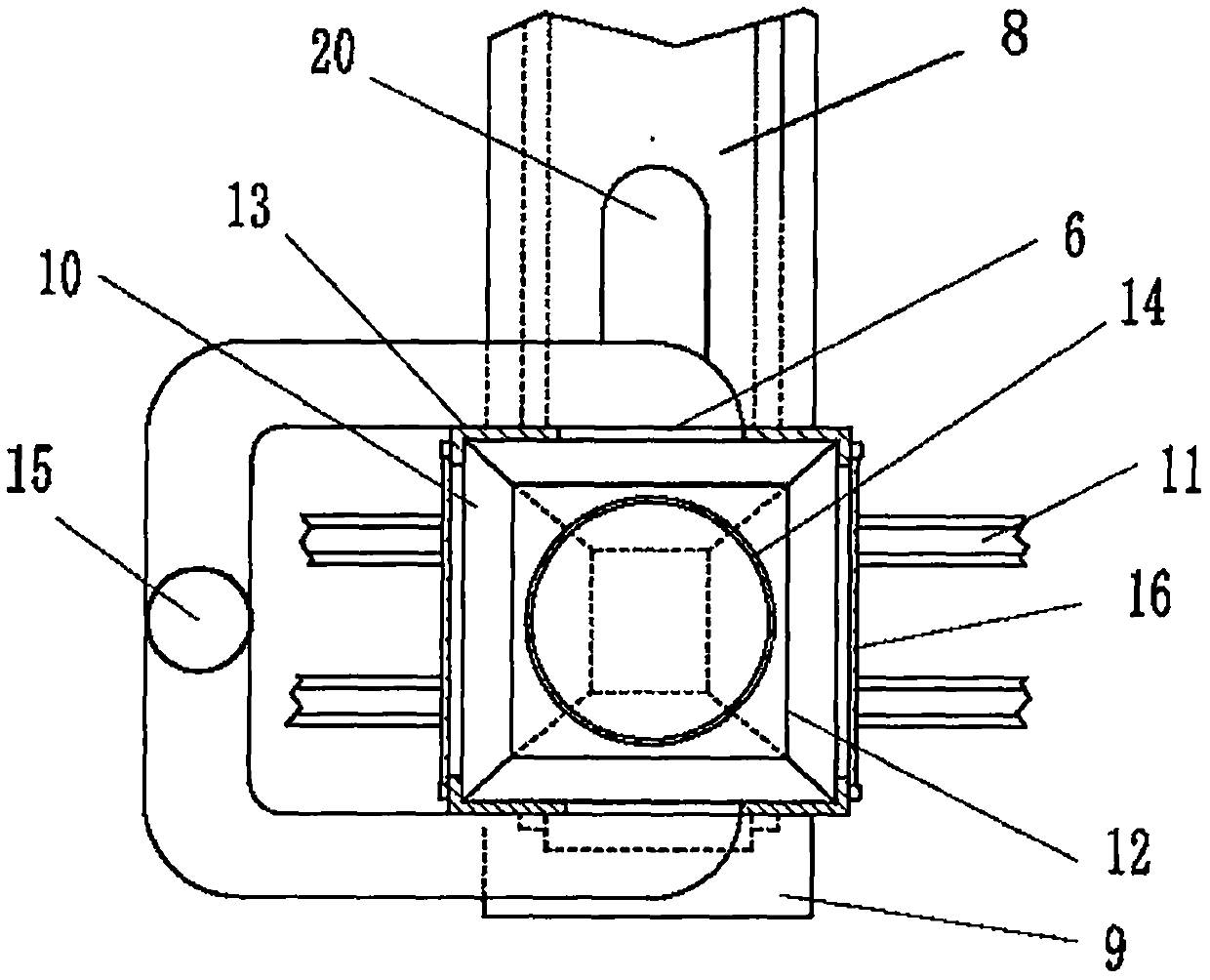

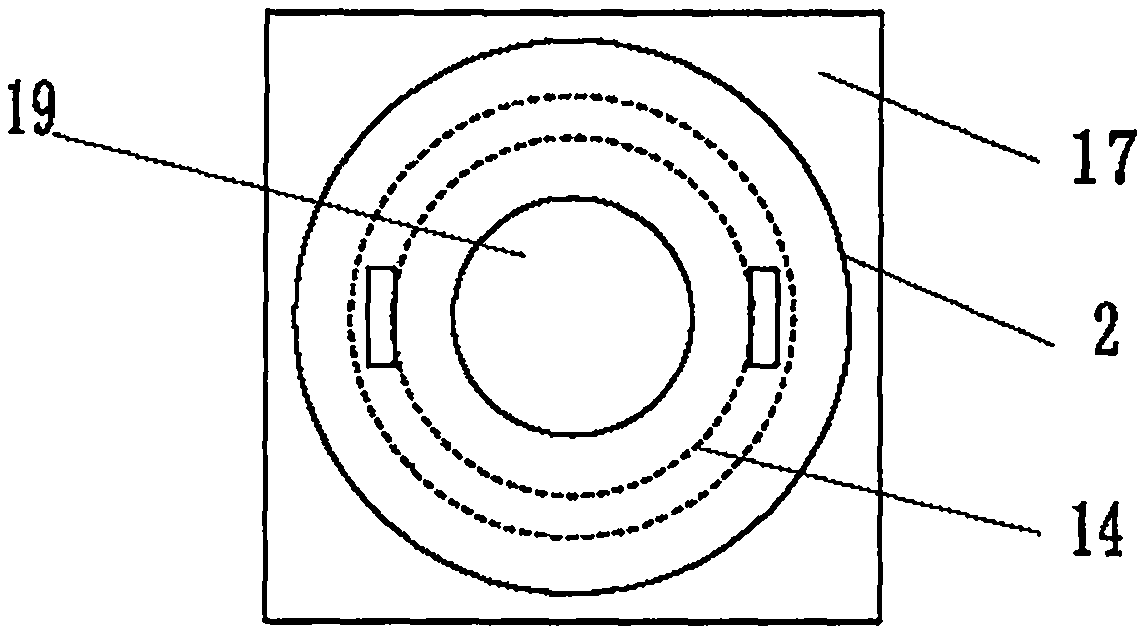

[0032] A device for cleaning the fused magnesia fused lump, such as figure 1 , figure 2 , image 3 As shown, it includes sealed dust removal room, underburned material output system and drum lifting system.

[0033] The sealed dust removal room includes a trolley track 11, a dust removal room 13, a sealed door 16, a dust removal port 6, a trolley 12 and a furnace shell 14. The dust removal room 13 is a square structure, the height is higher than the furnace shell 14 height, the dust removal room 13 is fixed on the ground, the trolley track 11 is laid on the ground in the dust removal room 13, the trolley 12 is on the track 11, and the trolley 12 is the installation Furnace shell 14 with frit, said furnace shell 14 has hanging lugs 7, on the wall surface of the dust removal room 13 perpendicular to the track direction, there are respectively sealed doors 16, and in the dust removal room along the wall surface of the track direction The upper part is provided with dust remov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap