A kind of preparation method of cobalt blue/clay mineral hybrid pigment prepared by solid phase method

A technology of clay minerals and solid-phase method, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., to achieve the effects of high yield, simple production process, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

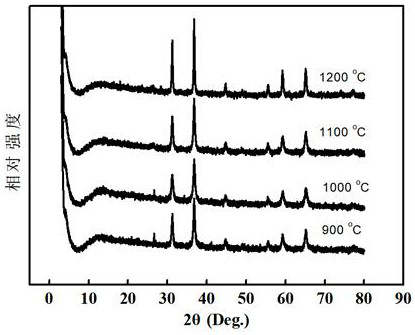

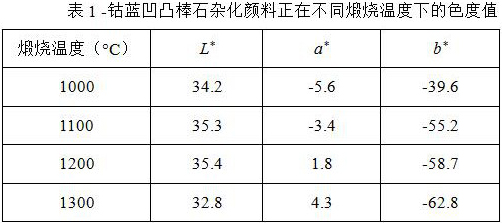

[0019] Preparation of cobalt blue hybrid pigments: Accurately weigh 109 g of attapulgite, 83 g of dicobalt trioxide, and 102 g of alumina and mix evenly. The resulting mixture is placed in a calciner and crystallized at 1000 °C for 2 h to obtain a bright Blue cobalt blue hybrid pigment, the sample number is S0, and the yield is 97.28%.

Embodiment 2

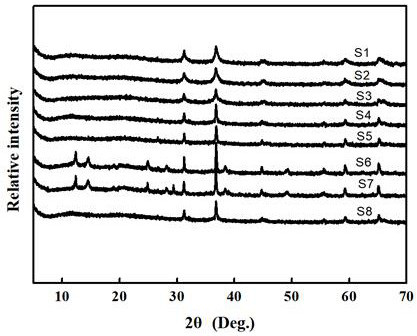

[0021] Preparation of cobalt blue hybrid pigment: Accurately weigh 219.95 g of halloysite, 83 g of dicobalt trioxide, and 204 g of alumina and mix evenly. The resulting mixture is placed in a calciner and crystallized at 1100 °C for 2 h to obtain a bright Blue cobalt blue hybrid pigment, the sample number is S1, and the yield is 98.42%.

Embodiment 3

[0023] Preparation of cobalt blue hybrid pigment: Accurately weigh 218 g of kaolinite, 83.13 g of tricobalt tetroxide, and 51 g of alumina and mix evenly. The resulting mixture is placed in a calciner and crystallized at 1200 °C for 2 h to obtain a bright blue color. Cobalt blue hybrid pigment, the sample number is S2, and the yield is 98.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com