Heavy-load soft-start speed reducer

A technology of reducer and soft start, which is applied in the direction of mechanical equipment, transmission devices, brake types, etc., can solve the problems of small reduction ratio range, large space occupied by the reducer, and low transmission efficiency, so as to reduce the space occupied by installation and solve the problem of The effect of poor shaft alignment and wide reduction ratio range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

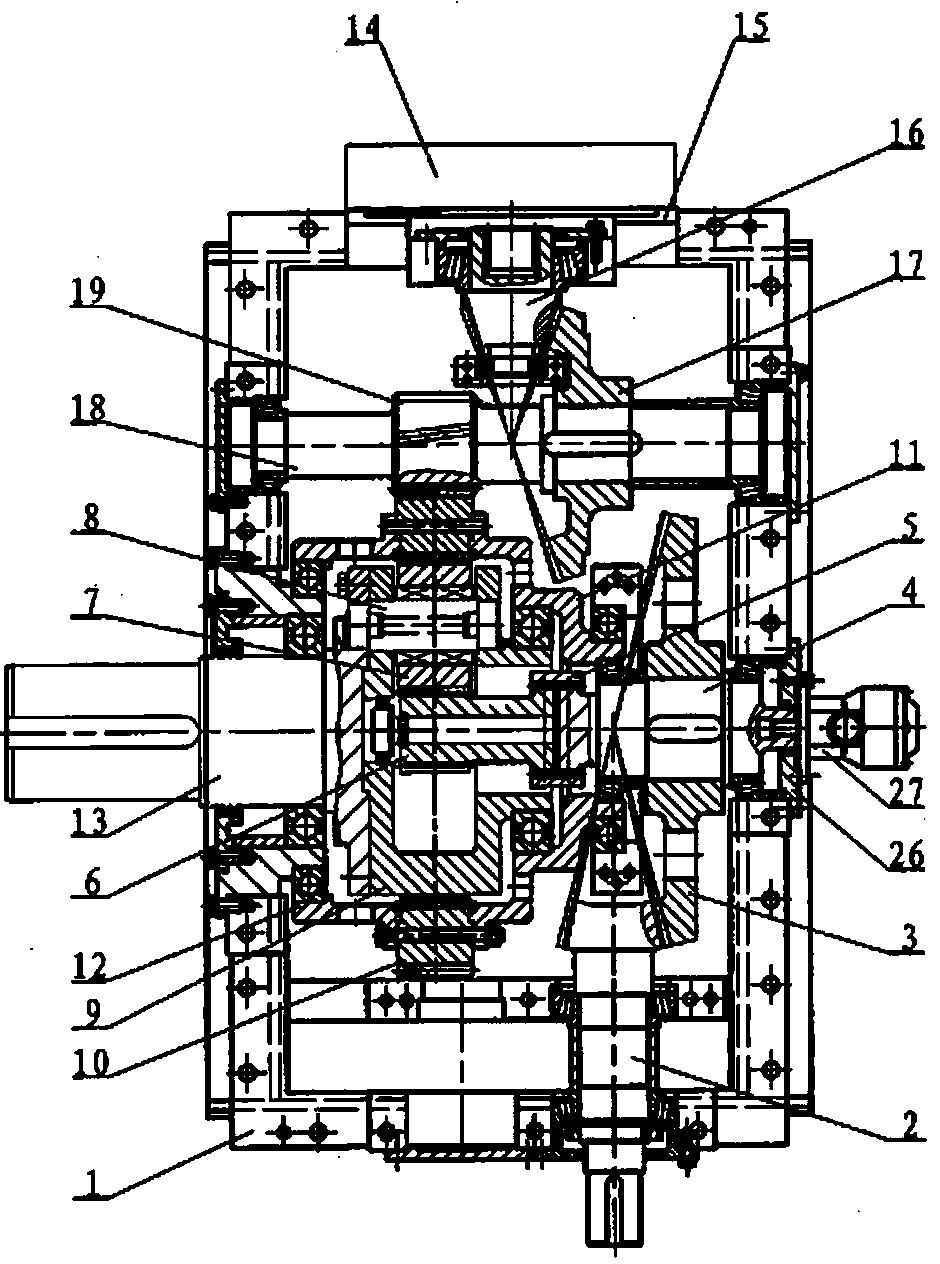

[0021] figure 1Embodiment 1 shown, a heavy-duty soft-start reducer mainly includes a box body 1, a deceleration bevel gear shaft 2, a deceleration bevel gear 3, a transition shaft 4, a floating gear sleeve 5, a sun gear 6, a planetary gear 7, and a planetary shaft 8. Planet carrier 9, inner and outer ring gears 10, ring gear front support 11, ring gear rear support 12, output shaft 13, hydraulic brake 14, speed-up bevel gear shaft 16, speed-up bevel gear 17, speed-up gear shaft 18 , Speed-up gear 19 and two-way lubricating oil pump 27. One end of the box body 1 supports the deceleration bevel gear shaft 2 through bearings. The transition shaft 4, the speed-increase gear shaft 18 and the ring gear front and rear supports 11 and 12 are supported in the box body 1 through bearings. The transition shaft 4 is connected with the deceleration bevel gear. 3. The deceleration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com