Tea leaf drying device

A drying device and tea technology, applied in tea drying, drying gas arrangement, drying solid materials, etc., can solve the problems of loss of essential oils, unsuitable for sweet-scented osmanthus, no recycling of essential oils, etc., and achieve pollution reduction, simple structure, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

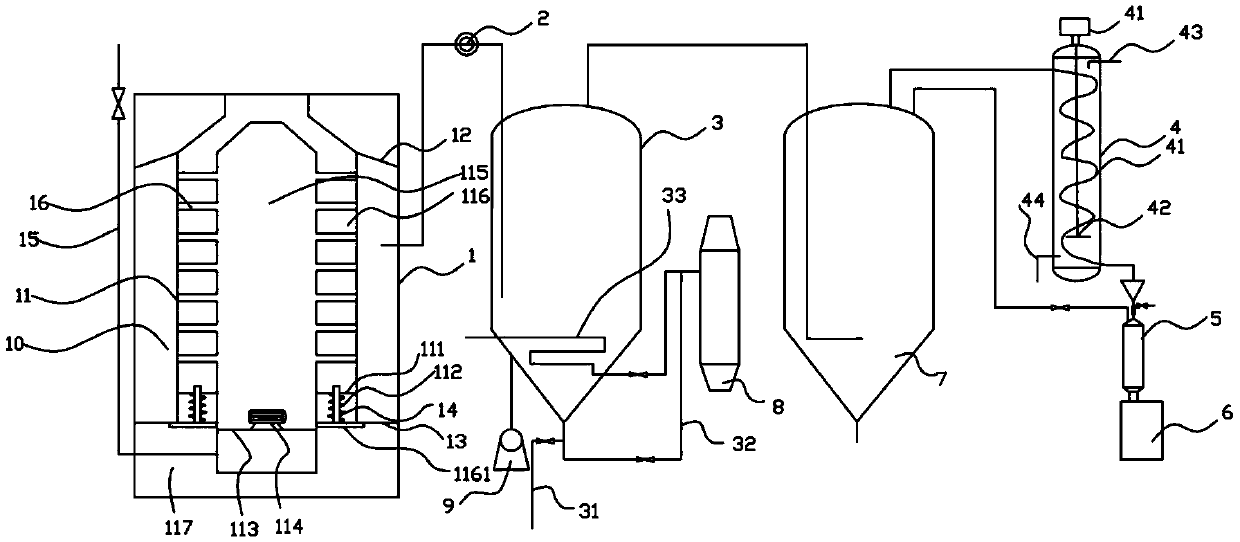

[0021] The tea drying device includes a drying box 1, the gas recovery chamber 10 passes through the pipeline and the fan 2, the first distillation kettle 3, the second distillation kettle 7, the condenser 4, the essential oil separation device 5, and the warm water storage tank 6 pass through the pipeline in sequence connection, the inside of the drying box 1 is provided with a hollow inner box 11, the gas recovery cavity 10 is between the outside of the inner box 11 and the inner wall of the drying box 1, and the inner box 11 includes an inner cavity 115 from the inside to the outside Four drying chambers 116 extending outward from the outer facade of the inner cavity 115;

[0022] The outside of the first still 3 is provided with a steam provider 8, the steam provider 8 communicates with the bottom of the first still 3 through a first steam pipe 32, and the steam provider 8 passes through a second steam pipe 33. Inside the first still 3 , the second steam pipeline 33 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com