Reciprocating type rock fracture friction-seepage characteristic test device and test method

A technology for testing rock cracks and properties, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength and strength properties of materials, etc. It can solve the problem that the measurement results are not accurate enough, the upper and lower crack surfaces cannot be fully contacted, and rock cracks cannot be measured at the same time Friction characteristics and fracture permeability evolution law, to achieve the effects of avoiding earthquake slip, stable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

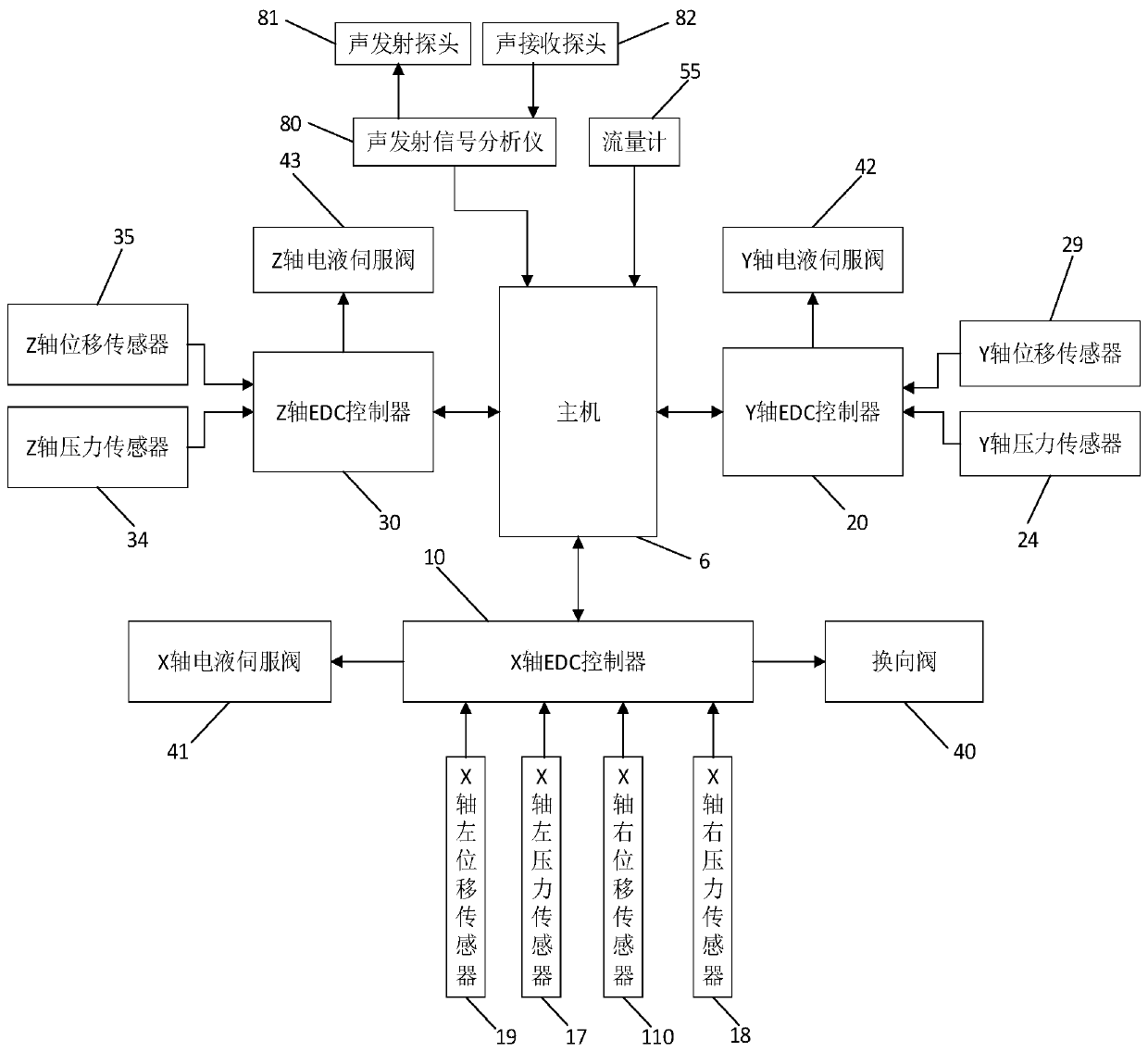

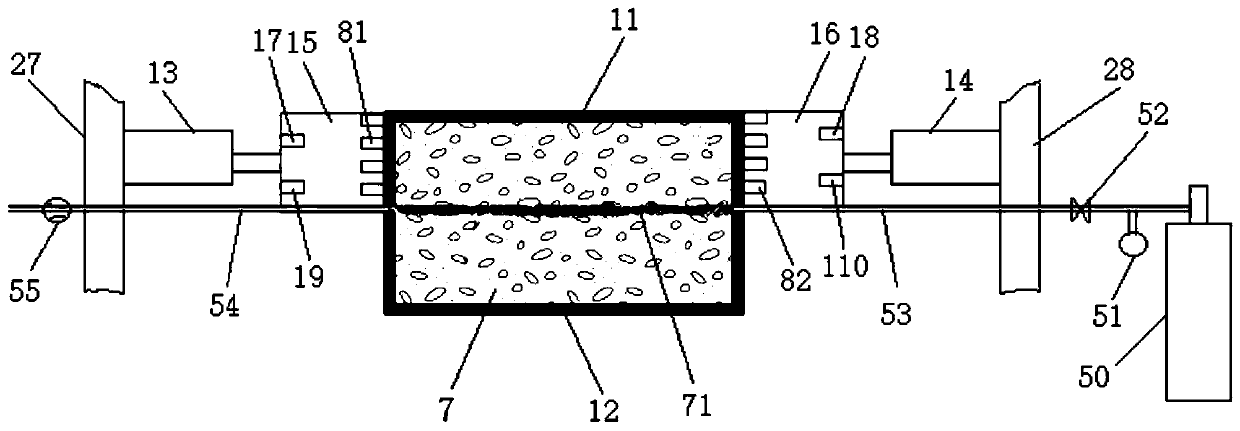

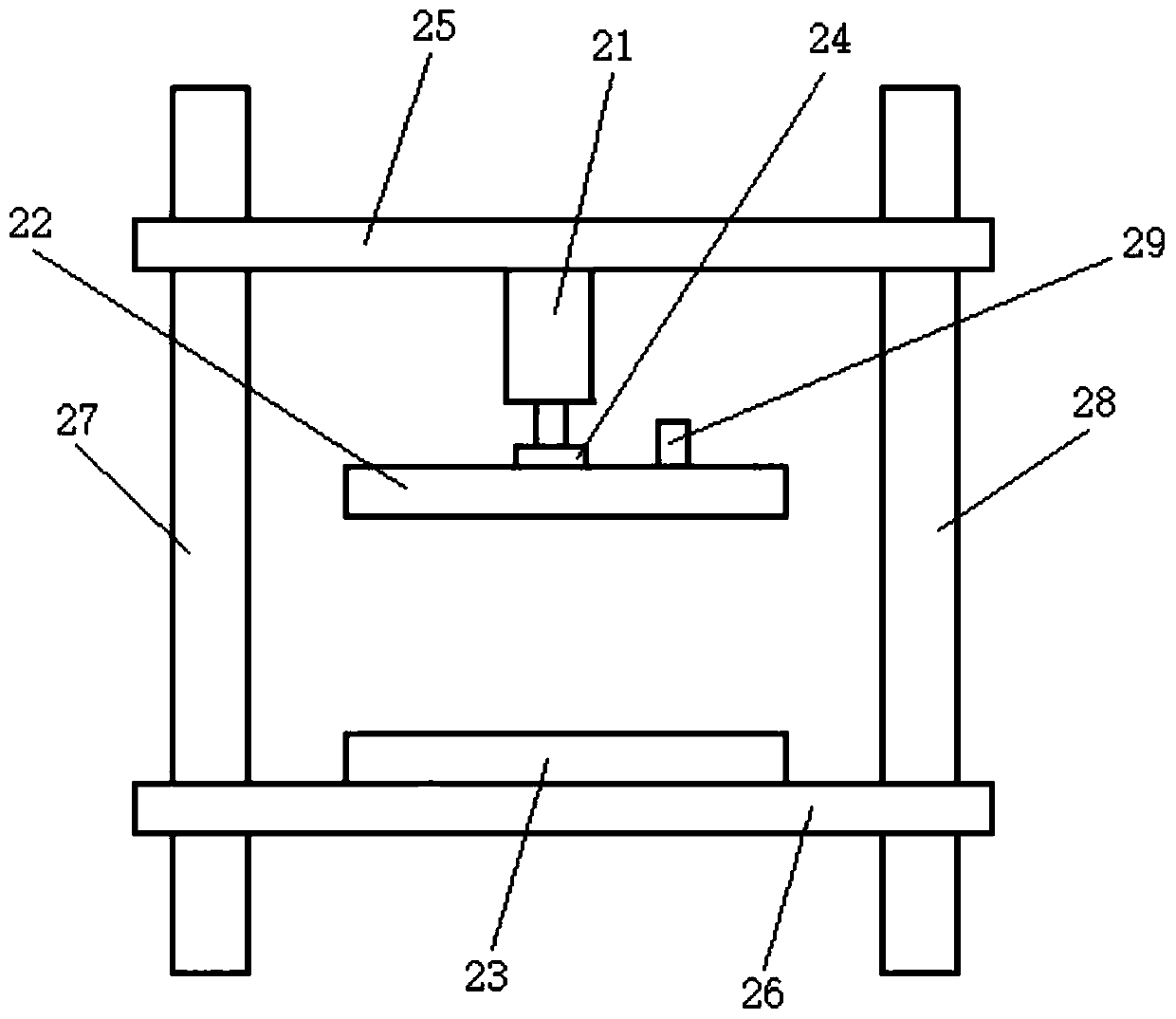

[0035] Such as Figure 1 to Figure 4 The shown reciprocating rock fracture friction-seepage characteristics testing device includes X-axis shear system, Y-axis stress loading system, Z-axis stress loading system, servo oil source system, pore pressure loading system, acoustic emission detection system and host 6 .

[0036] The servo oil source system (being the prior art) is the power source of the X-axis shearing force, the Y-axis stress loading, and the Z-axis stress loading. Valve, pressure gauge, air filter, transducer, reversing valve 40 (electromagnetic reversing valve), X-axis electro-hydraulic servo valve 41, Y-axis electro-hydraulic servo valve 42, Z-axis electro-hydraulic servo valve 43, etc. Composition, in order to achieve precision servo, the X-axis electro-hydraulic servo valve 41, the Y-axis electro-hydraulic servo valve 42, and the Z-axis electro-hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com