LED epitaxial growth method for reducing dislocation density of quantum well

A technology of epitaxial growth and quantum well, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of quantum well dislocation defects, low luminous efficiency, and high leakage of LED devices, so as to reduce the growth rate of GaN and improve the crystal quality , The effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0044] Example 1:

Example Embodiment

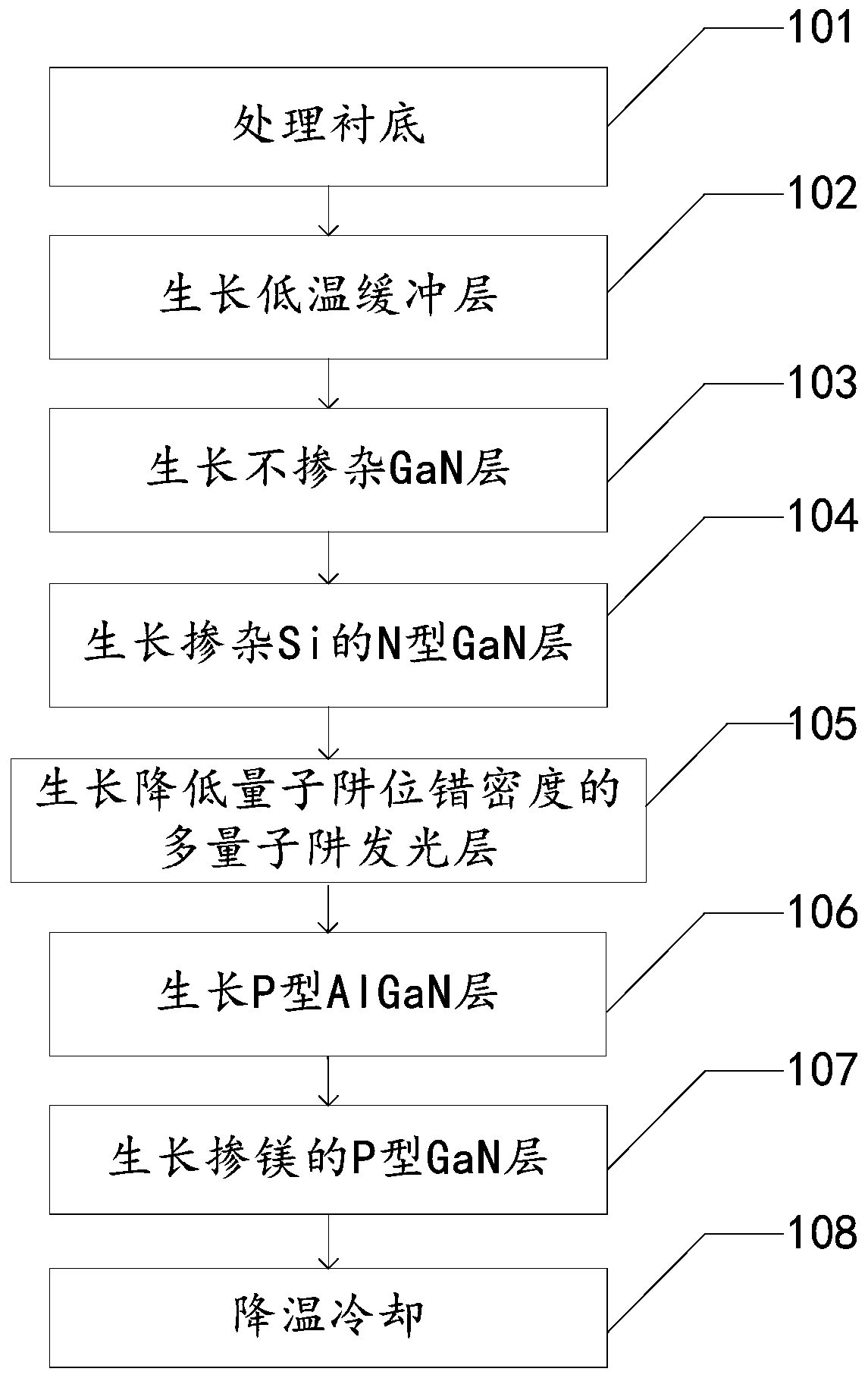

[0045] In this embodiment, MOCVD is used to grow high-brightness GaN-based LED epitaxial wafers, and high-purity H 2 Or high purity N 2 Or high purity H 2 And high purity N 2 Mixed gas as carrier gas, high purity NH 3 As the N source, trimethylgallium (TMGa) as the gallium source, trimethylindium (TMIn) as the indium source, silane (SiH 4 ) As the N-type dopant, trimethyl aluminum (TMAl) as the aluminum source, and magnesium cerene (CP 2 Mg) is used as the P-type dopant, the substrate is faceted sapphire, and the pressure of the reaction chamber is between 150 mbar and 600 mbar. See figure 1 Shown is a specific embodiment of the LED epitaxial growth method for reducing the dislocation density of quantum wells according to the application, and the method includes:

[0046] Step 101: processing the sapphire substrate, specifically, processing the sapphire substrate for 5-10 minutes under a hydrogen atmosphere at a temperature of 1000-1020°C and a pressure controlled at 100-150mbar.

...

Example Embodiment

[0058] Example 2:

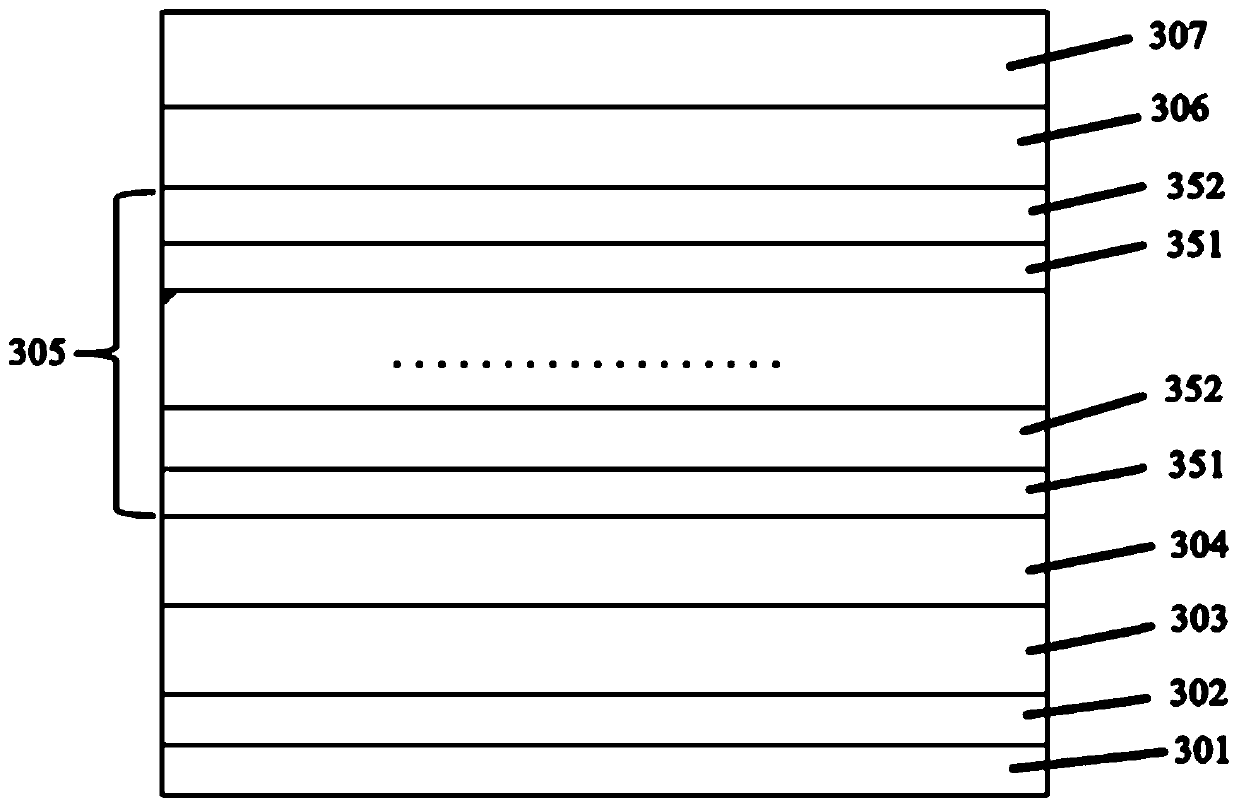

[0059] Such as Figure 4 As shown, the schematic flow chart of the LED epitaxial growth method for reducing the dislocation density of the quantum well in this embodiment, the method includes:

[0060] In step 401, the sapphire substrate is processed, specifically, the sapphire substrate is processed for 5-10 minutes in a hydrogen atmosphere at a temperature of 1000-1020°C and a pressure controlled at 100-150mbar.

[0061] Step 402: Growing a low-temperature buffer GaN layer on a quantum well sapphire substrate: cooling down to 520-550°C, controlling the pressure at 500-1000 mbar, using TMGa as the MO source, and TMGa dosage of 40-100 sccm, in the quantum well sapphire A low-temperature buffer GaN layer with a thickness of 20-30 nm is grown on the substrate.

[0062] Step 403: Growing an undoped GaN layer on a quantum well sapphire substrate: heating to 1030-1080°C, keeping the temperature constant, controlling the pressure at 150-500mbar, using TMGa as the MO sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com