Shoe with antibacterial sole and preparation process thereof

A technology for shoes and soles, applied in the field of shoes, can solve the problems of causing athlete's foot, foot odor, breeding of bacteria, etc., and achieve the effect of lasting antibacterial effect, enhancing antibacterial effect, and improving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

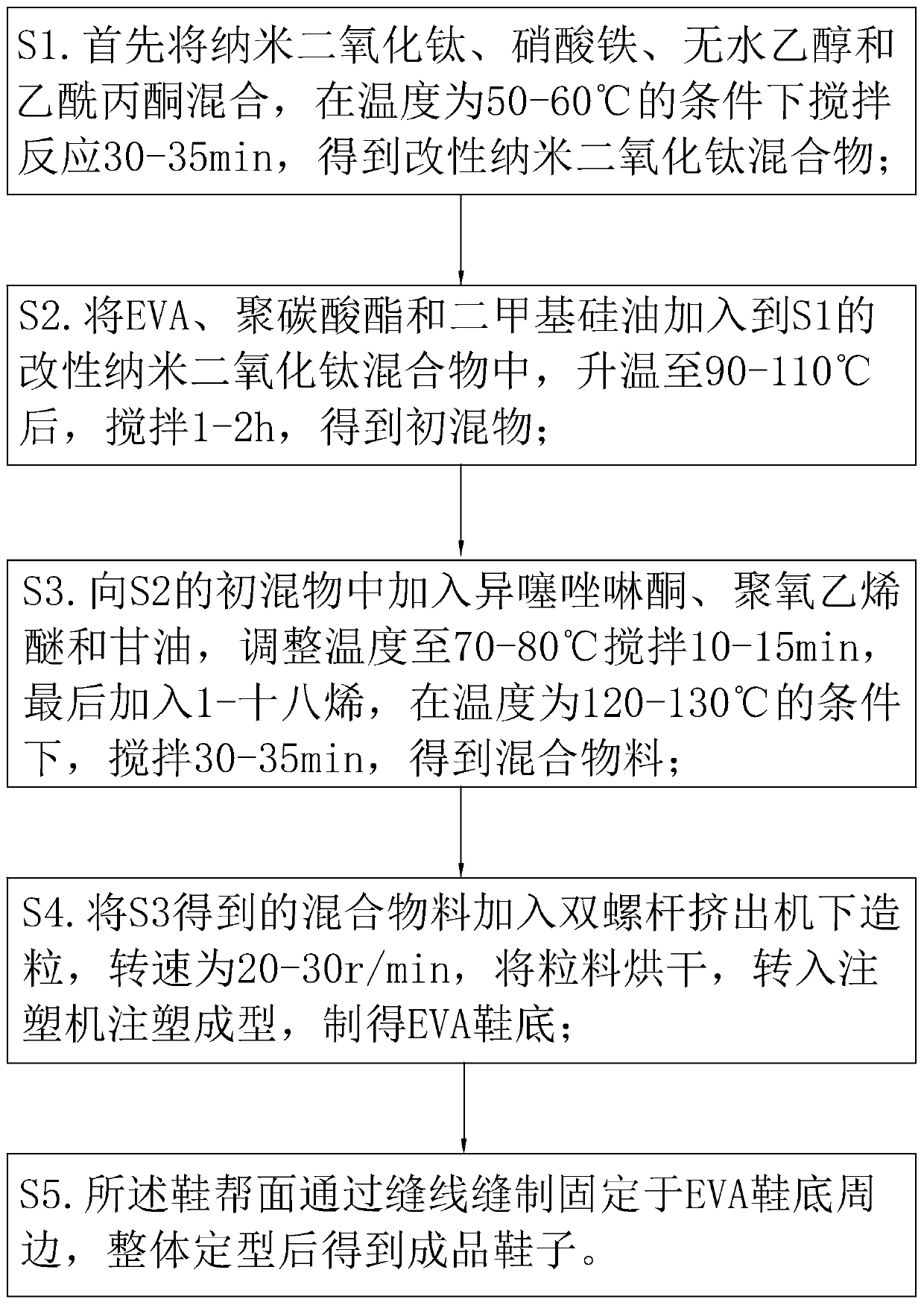

[0046] refer to figure 1 , is the preparation technology of a kind of sole antibacterial shoe disclosed by the present invention, comprises the following steps:

[0047] S1. First mix nano-titanium dioxide, ferric nitrate, absolute ethanol and acetylacetone, and stir and react for 30 minutes at a temperature of 50° C. to obtain a modified nano-titanium dioxide mixture;

[0048] S2. Add EVA, polycarbonate and simethicone to the modified nano-titanium dioxide mixture of S1, heat up to 90° C., and stir for 1 hour to obtain the primary mixture;

[0049] S3. Add isothiazolinone, polyoxyethylene ether and glycerin to the initial mixture of S2, adjust the temperature to 70°C and stir for 10 minutes, finally add 1-octadecene, and stir for 30 minutes at a temperature of 120°C. get mixed material;

[0050] S4. Add the mixed material obtained in S3 to granulate under the twin-screw extruder, the rotating speed is 10r / min, the pellets are dried, and then transferred to the injection mol...

Embodiment 2

[0054] refer to figure 1 , is the preparation technology of a kind of sole antibacterial shoe disclosed by the present invention, comprises the following steps:

[0055] S1. First mix nano-titanium dioxide, ferric nitrate, absolute ethanol and acetylacetone, and stir and react for 35 minutes at a temperature of 60° C. to obtain a modified nano-titanium dioxide mixture;

[0056] S2. Add EVA, polycarbonate and simethicone to the modified nano-titanium dioxide mixture of S1, heat up to 110° C., and stir for 2 hours to obtain the primary mixture;

[0057] S3. Add isothiazolinone, polyoxyethylene ether and glycerin to the initial mixture of S2, adjust the temperature to 80°C and stir for 15 minutes, and finally add 1-octadecene, and stir for 35 minutes at a temperature of 130°C. get mixed material;

[0058] S4. Add the mixed material obtained in S3 to granulate under the twin-screw extruder, the rotating speed is 20r / min, the pellets are dried, and then transferred to the injecti...

Embodiment 3

[0062] refer to figure 1 , is the preparation technology of a kind of sole antibacterial shoe disclosed by the present invention, comprises the following steps:

[0063] S1. First mix nano-titanium dioxide, ferric nitrate, absolute ethanol and acetylacetone, and stir and react for 33 minutes at a temperature of 56° C. to obtain a modified nano-titanium dioxide mixture;

[0064] S2. Add EVA, polycarbonate and simethicone to the modified nano-titanium dioxide mixture of S1, heat up to 98°C, and stir for 1-2 hours to obtain the primary mixture;

[0065] S3. Add isothiazolinone, polyoxyethylene ether and glycerin to the initial mixture of S2, adjust the temperature to 75°C and stir for 12 minutes, finally add 1-octadecene, and stir for 35 minutes at a temperature of 124°C. get mixed material;

[0066] S4. Add the mixed material obtained in S3 to granulate under the twin-screw extruder, the rotating speed is 20r / min, the pellets are dried, and then transferred to the injection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com