Woodworking tenoning machine

A tenoning machine and woodworking technology, applied in the direction of wood processing equipment, manufacturing tools, dovetail tenon processing, etc., can solve the problems of low precision, low efficiency, low precision and low bearing capacity of the punched holes, so as to improve work efficiency, The effect of simple adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

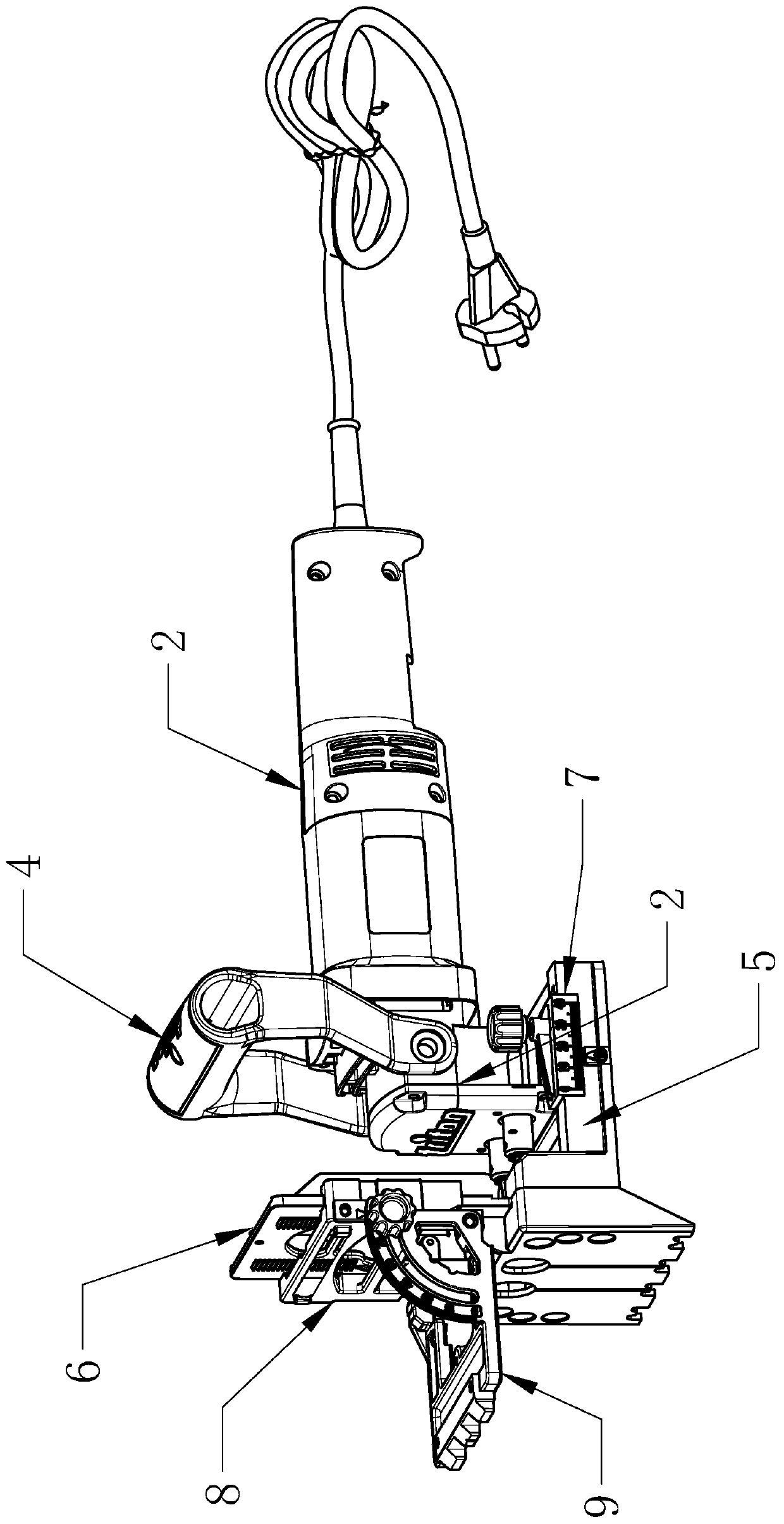

[0031] Such as figure 1 As shown, a woodworking tenoning machine includes a housing 1, a gear box 2 and a power motor 3, the housing 1 is fixedly connected to the gear box 2, the power motor 3 is fixedly arranged in the housing 1, and the gear box 2 It includes a box body 201 and a gear transmission assembly arranged in the box body 201. The box body 201 is provided with an outer cover 202. The outer cover 202 is installed on one side of the box body 201 and forms a seal. The outer cover 202 It is detachably connected with the box body 201, and a handle 4 is fixedly arranged on the box body 201, which is convenient for handling and carrying of the tenoning machine.

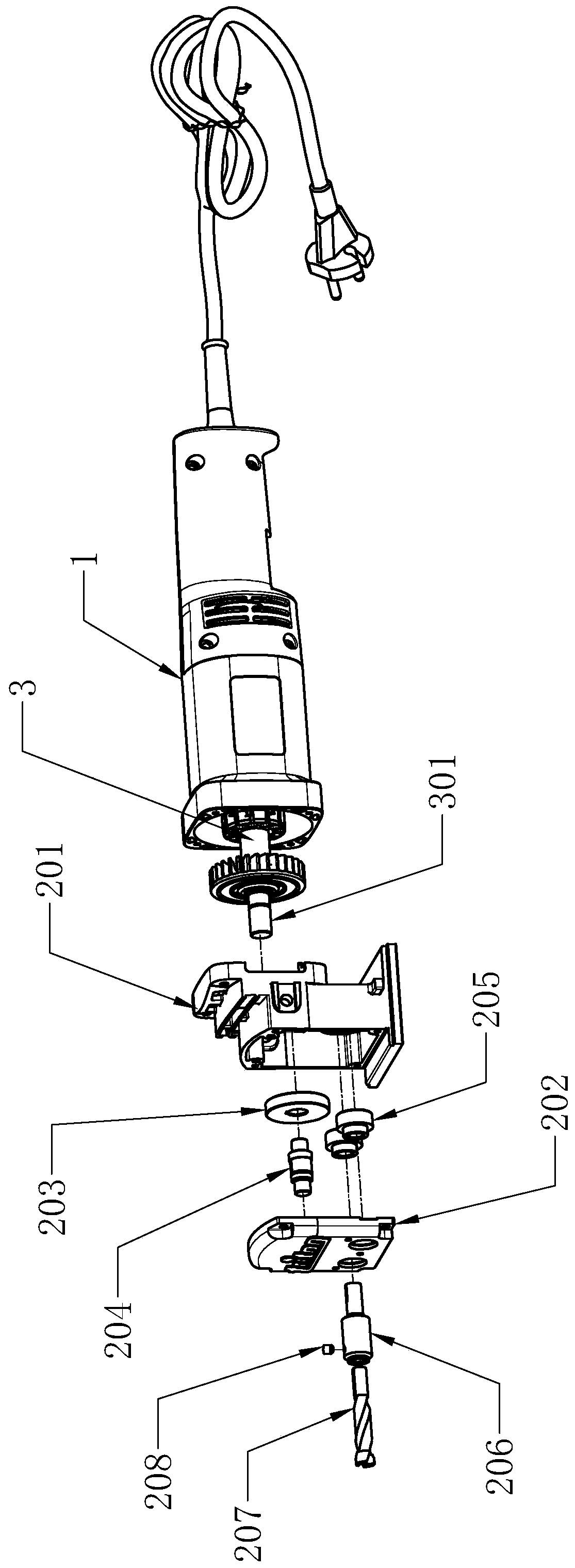

[0032] Such as figure 2 As shown, the gear transmissi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap