Flying dust treatment device for building construction site

A processing device and building construction technology, applied in combined devices, vehicle exterior cleaning devices, dispersed particle separation, etc., can solve the problems of inconvenient flushing, time-consuming and labor-intensive sludge cleaning, etc., and achieve reasonable design, avoid dust, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical features of the solution can be clearly described, and the solution will be described through specific implementation modes below.

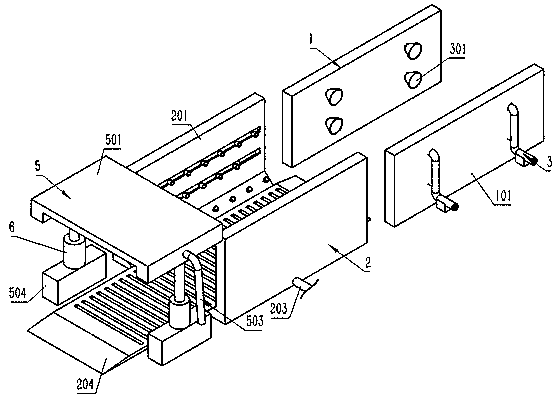

[0039] see Figure 1 to Figure 12 As shown, this embodiment is a reasonable design, simple structure, safe and reliable dust treatment device for construction site dust removal for vehicles entering and leaving the construction site.

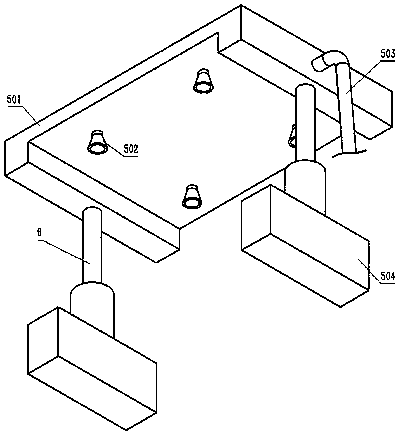

[0040] The technical solution adopted by the present invention to solve the technical problems is: the present invention provides a dust treatment device for construction site, including dust removal system 1, flushing system 2 and spraying system 5, dust removal system 1, flushing system 2 and spraying system 5 Straight line settings in turn.

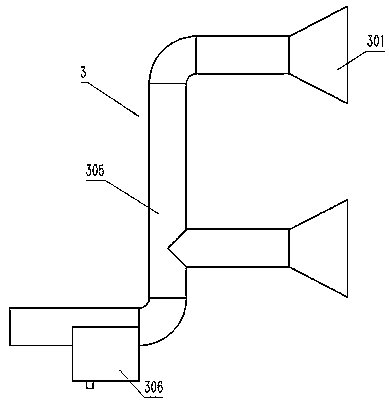

[0041] The dust removal system 1 includes two opposite dust removal walls 101, on which a number of dust removal assemblies 3 are arranged, and each dust removal assembly 3 includes a dust collection cover 301, a suction fan 302, a filter plate 303 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com