Anaerobic-aerobic sewage treatment method based on three-phase separation

A sewage treatment method, three-phase separation technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. problems such as low efficiency and heavy equipment maintenance, to achieve the effect of reducing equipment footprint, high sewage treatment efficiency, and improving functional integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

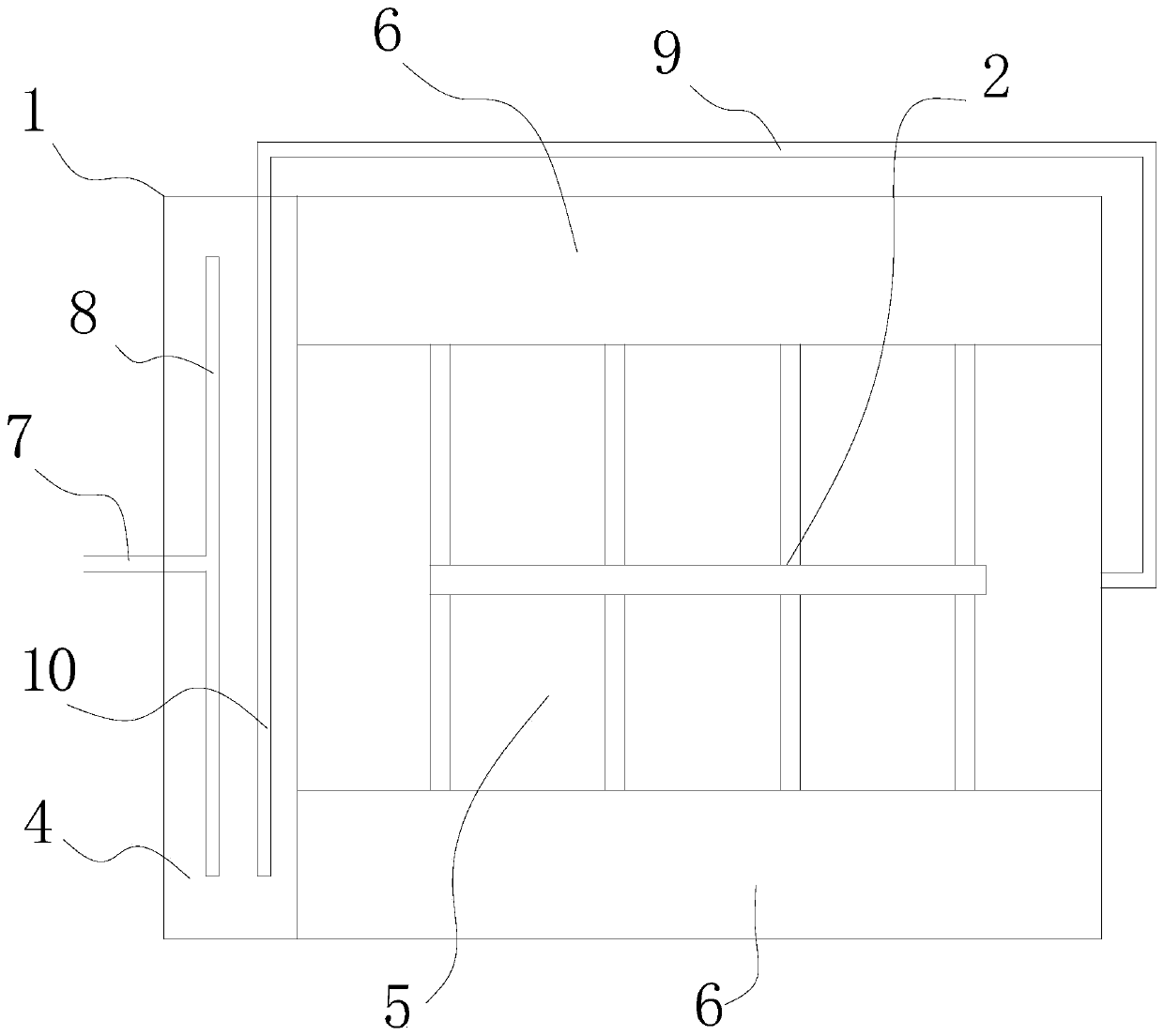

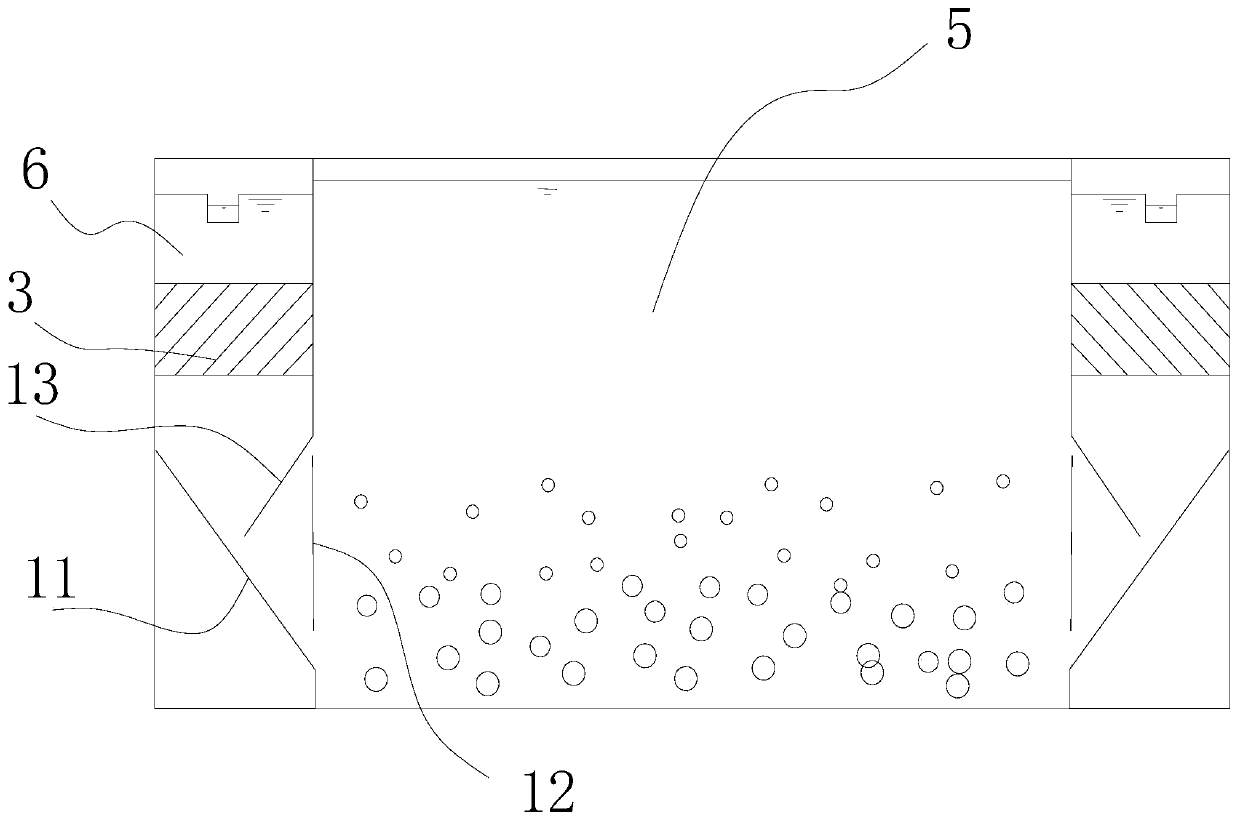

[0025] The first embodiment, such as figure 1 , 2 As shown, the sewage treatment system includes a housing 1, a water inlet component, a digestive fluid return component, an aeration tube 2, an inclined tube packing 3, and a combined packing.

[0026] The shell 1 is formed by welding plates. The overall shape of the shell 1 is a cuboid. The inside of the shell 1 is divided to form an anaerobic zone 4, an aerobic zone 5 and two three-phase separation precipitation zones 6; because the top of the shell 1 There is no cover structure, so the anaerobic zone 4, the aerobic zone 5, and the three-phase separation and precipitation zone 6 are all open. Both the anaerobic zone 4 and the three-phase separation precipitation zone 6 are flat cuboid structures; The side where the side is located, so that the anaerobic zone 4 is just distributed on the side where the broad side of the two three-phase separation sedimentation zones 6 is located, and the four areas are combined to form a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com