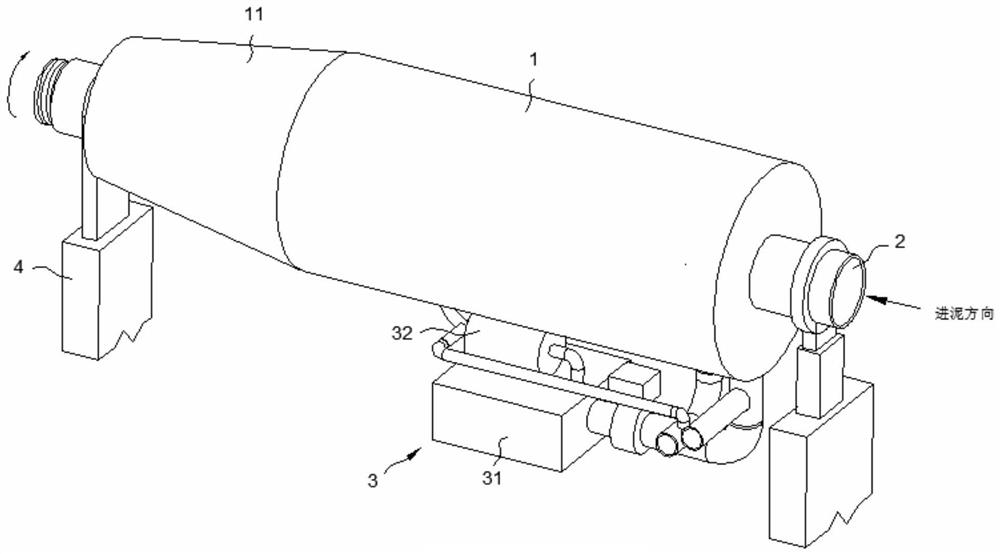

A centrifugal separation device for river sludge treatment process

A technology for sludge treatment and centrifugal separation, applied in sludge treatment, water/sludge/sewage treatment, centrifuges with rotating drums, etc. and other problems, to achieve the effect of improving service life, sufficient dehydration, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

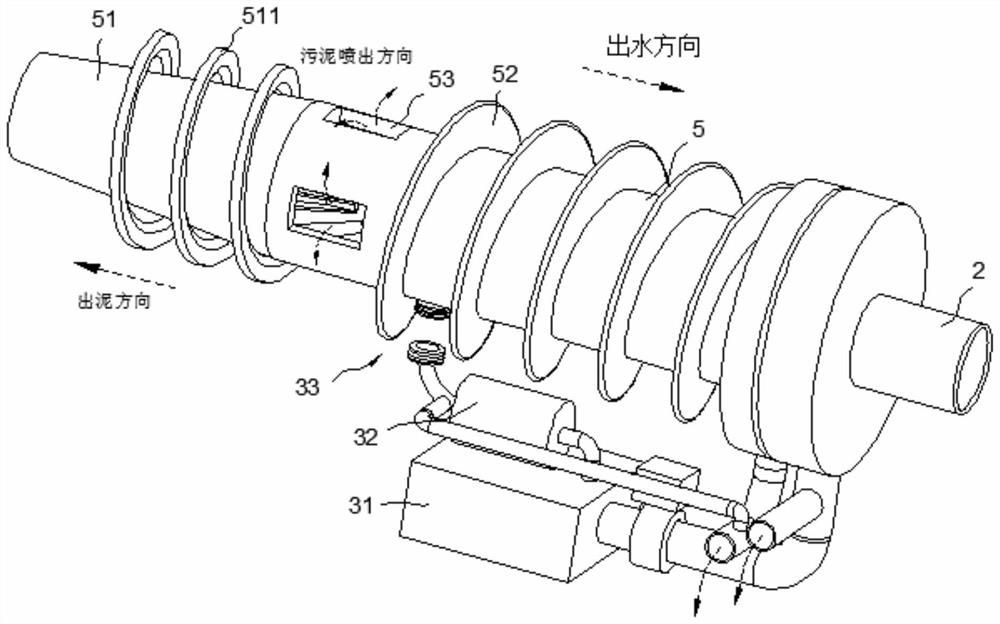

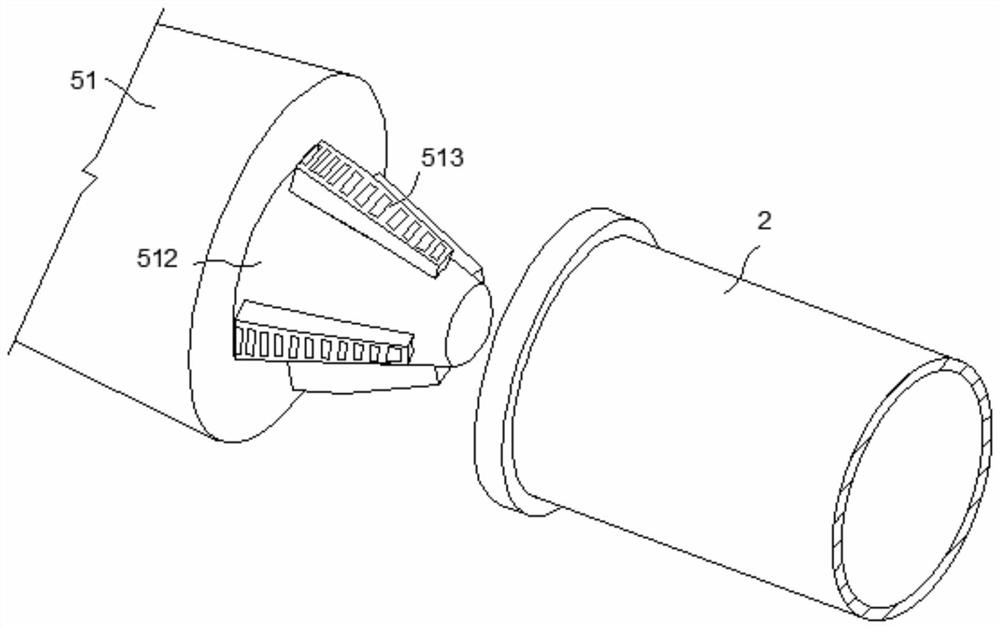

[0034] Embodiment: When using the centrifugal separation device, when working, the external torque drives the mud inlet pipe 2 and the drum 5 to rotate, and due to the centrifugal force, the sludge discharged from the mud inlet pipe 2 is sent into the drum 5 , the differential clutch is used to make the mud inlet pipe 2 and the drum 5 have a speed difference, increase the exit speed of the mud in the mud inlet pipe 2, so that the mud can be thrown into the shell 1; when the rectifier cone 512 works normally, it is fixed at the second On the second tapered part 51, the mud coming in from the mud inlet pipe 2 is dispersed by the rectifying cone 512 and then rotated by the scraper 513 and thrown out of the mud hole 53 to spread out to better separate the mud and water. During normal operation, the rectifying cone is used to The sludge is diverted to make it convenient to switch between the two functions; when cleaning the mud, first start the first motor 55, and its output shaft d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com