Preparation method of organic fertilizer

An organic fertilizer and composting technology, which is applied in the preparation of organic fertilizers, organic fertilizer equipment, organic fertilizers, etc., can solve the problems of heat loss in compost heaps, reduced fermentation efficiency, failure of organic fertilizer preparation, etc., to improve oxygen-containing capacity , the effect of particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

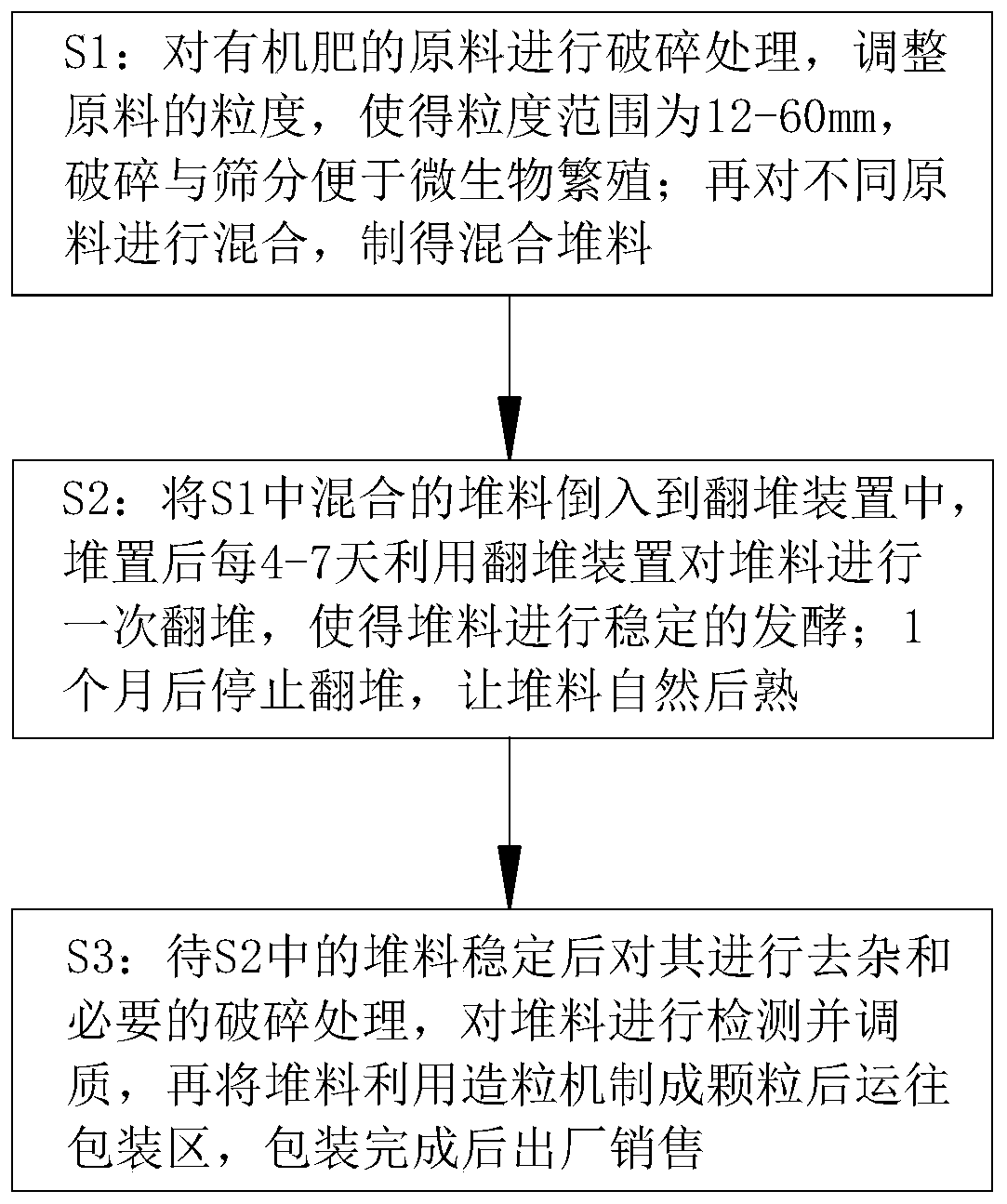

[0027] Such as Figure 1 to Figure 6 Shown, the preparation method of a kind of organic fertilizer of the present invention comprises the following steps:

[0028] S1: Crushing the raw materials of organic fertilizers, adjusting the particle size of the raw materials, so that the particle size range is 12-60mm, and then mixing different raw materials to make a mixed pile. Crushing and screening can increase the surface area of the raw materials, which is convenient Microbial reproduction, increase fermentation speed;

[0029] S2: Pour the stacking material mixed in S1 into the stacking device, and use the stacking device to turn the stacking material, so that the stacking material can be fermented stably; after stacking, it can be turned once every 4-7 days, After 1 month, you can stop turning the pile and let it mature naturally; blowing air into the pile increases the amount of oxygen required by the pile and improves the fermentation efficiency;

[0030]S3: After the st...

Embodiment approach

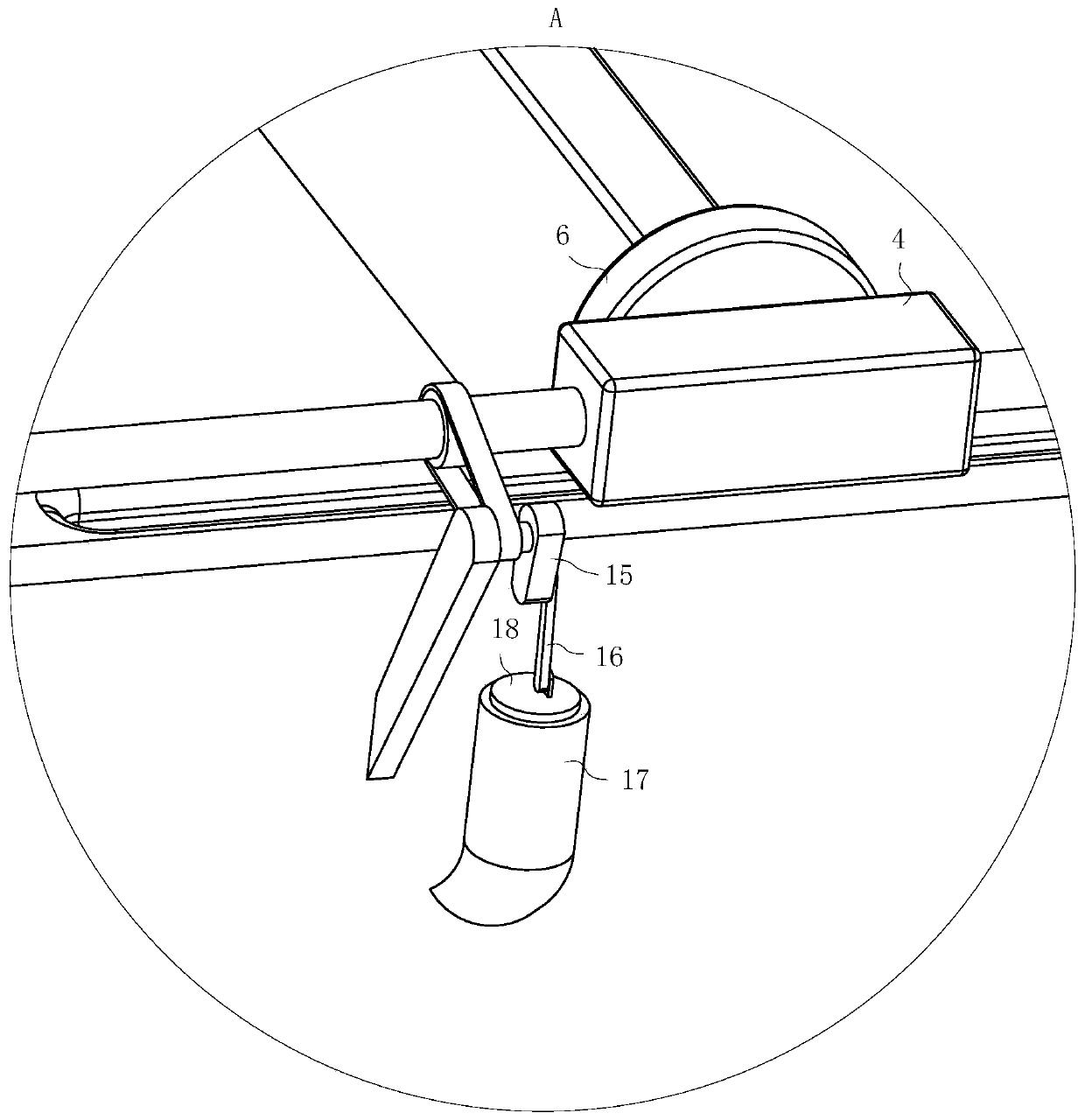

[0033] As a specific embodiment of the present invention, the air duct 19 is located on the side wall at the end of the fermentation tank 1, the angle between the air duct 19 and the bottom surface of the fermentation tank 1 is an acute angle, and the air duct 19 is located at Below the temperature-insulating cloth 13, during use, the air duct 19 is arranged at the end of the fermentation tank 1 so that the gas blown out from the air duct 19 flows from one end of the fermentation tank 1 to the other end of the fermentation tank 1, and the gas moves during the gas movement. It is gradually heated, so that the gas temperature gradually rises; the gas temperature is kept consistent with the temperature in the fermentation tank 1, so that the influence of the gas on the fermentation is reduced, and the temperature change of the microbial production environment is avoided; the gas flows from one end of the fermentation tank 1 to the fermentation tank 1 The other end overflows the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com