Galanthamine dihydroxy naphthoate and preparation method thereof

A technology of galantamine pamoate compound and galantamine pamoate compound, which is applied in the field of amorphous galantamine pamoate and its preparation, can solve the problems of low solubility, light resistance, Problems such as solubility characteristics, poor stability, low solubility characteristics, stability and safety, etc., to achieve the effects of excellent solubility characteristics and stability, easy process, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

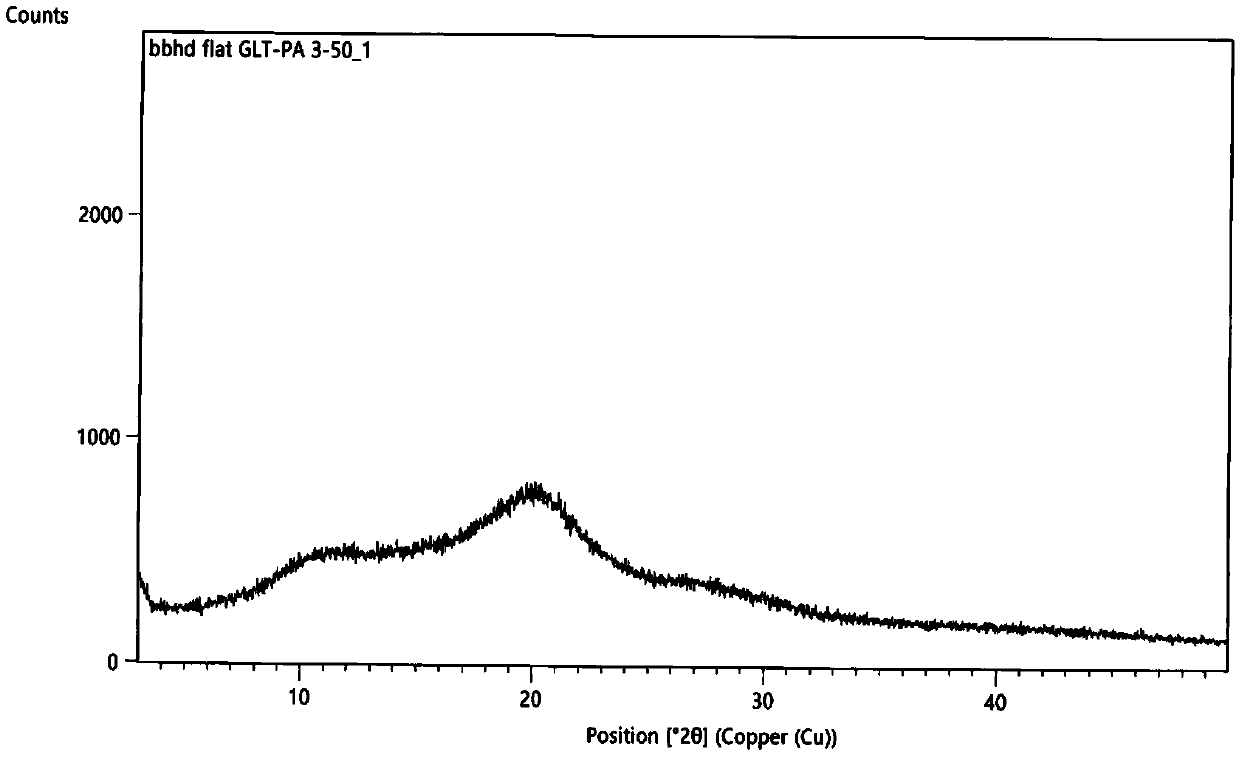

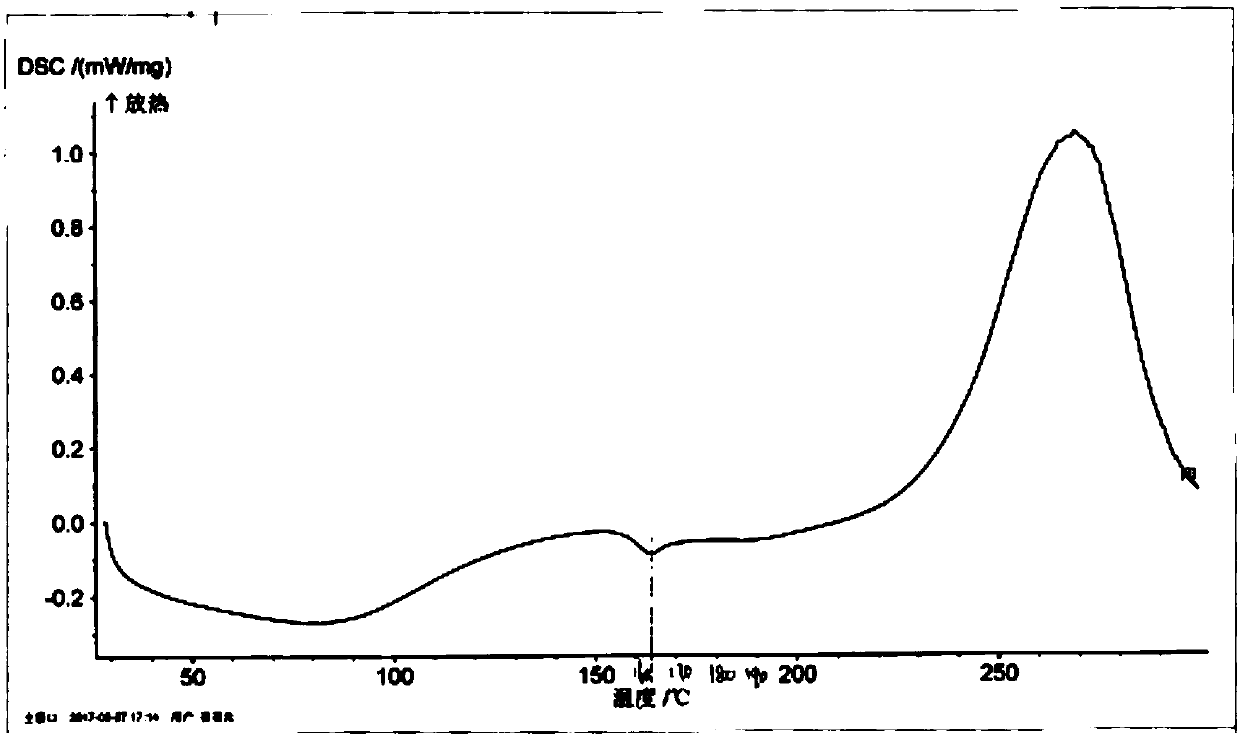

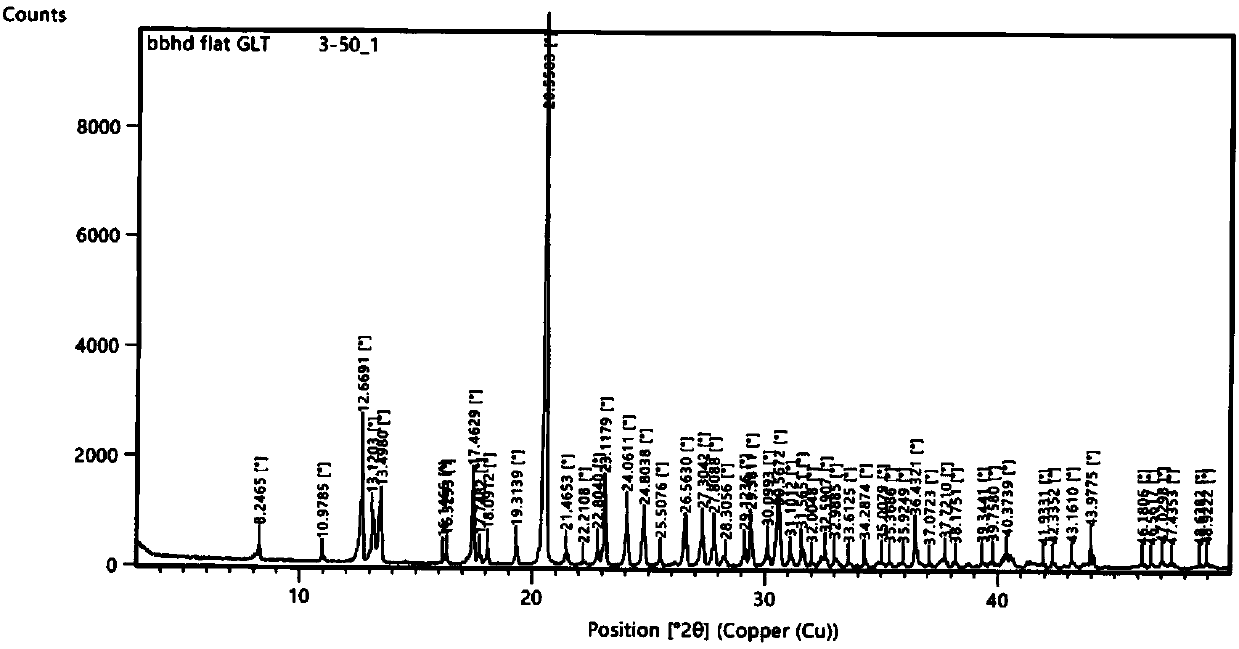

Image

Examples

Embodiment 1

[0037] Dissolve 2g of galantamine hydrobromide in ethanol solution (30mg / mL) of 20mL sodium hydroxide, after stirring for 30min, suction filter the insoluble matter, and concentrate the filtrate to obtain galantamine free base; Dissolve 1.0 g of base in 20 mL of dimethyl sulfoxide, add 100 mL of dimethyl sulfoxide solution containing 1.29 g of pamoic acid dropwise, and stir and react at 20°C for 6 hours; after the reaction, place the reaction solution in a 5°C Stand in the environment for 24 hours, filter with suction, and dry in vacuum at 50° C. for 2 hours to obtain a light yellow powder with a yield of 88.23% and a purity of 99.92%.

Embodiment 2

[0039] Dissolve 2g of galantamine hydrobromide in ethanol solution (20mg / mL) of 20mL sodium hydroxide, after stirring for 30min, suction filter the insoluble matter, and concentrate the filtrate to obtain galantamine free base; Dissolve 1.0g of base in 30mL of N,N-dimethylformamide, add dropwise 200mL of N,N-dimethylformamide solution containing 3.51g of pamoic acid, after the dropwise completion, stir and react at 40°C for 3 hours; After completion, the reaction solution was placed in an environment at 5° C. for 24 hours, filtered with suction, and vacuum-dried at 50° C. for 2 hours to obtain a light yellow powder with a yield of 79.22% and a purity of 99.91%.

Embodiment 3

[0041]Dissolve 2g of galantamine hydrobromide in ethanol solution (50mg / mL) of 20mL sodium hydroxide, after stirring for 30min, suction filter the insoluble matter, and concentrate the filtrate to obtain galantamine free base; Dissolve 1.0 g of base in 20 mL of 1,3-dimethyl-2-imidazolidinone, add dropwise 150 mL of 1,3-dimethyl-2-imidazolidinone solution containing 2.34 g of pamoic acid, and dropwise, Stir and react at 60°C for 2 hours; place the reaction solution in an environment at 5°C for 24 hours, filter it with suction, and dry it in vacuum at 50°C for 2 hours to obtain a light yellow powder with a yield of 76.35% and a purity of 99.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com