Acid-base dual-response hollow mesoporous silica composite nano container, self-repairing anticorrosive coating and preparation method thereof

A technology of mesoporous silica and nano-containers, which is applied in anti-corrosion coatings, epoxy resin coatings, dyed polymer organic compound treatment, etc., can solve problems such as easy collapse, improve compatibility and prevent corrosion inhibitors leaked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of ZIF-8 self-sacrificing template:

[0037] Dissolve zinc nitrate hexahydrate in 100mL methanol to form solution A, the concentration of zinc nitrate is 42mM; weigh 2-methylimidazole and dissolve it in 100mL methanol to form solution B, the concentration of 2-methylimidazole is 0.65M. Pour solution B into solution A, and stir the mixed solution vigorously for 3h at a stirring speed of 3000rpm / min. Wash by centrifugation, wash with methanol three times, and dry overnight at 60° C. to obtain ZIF-8 nanoparticles.

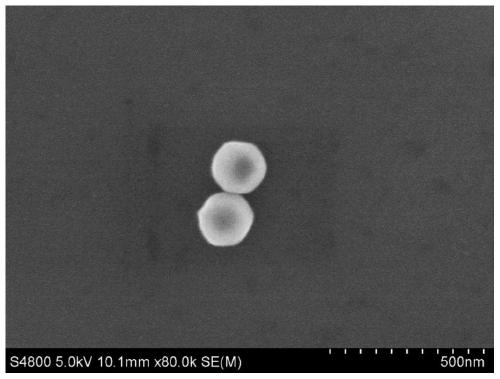

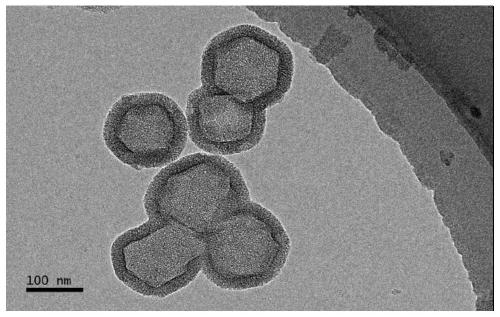

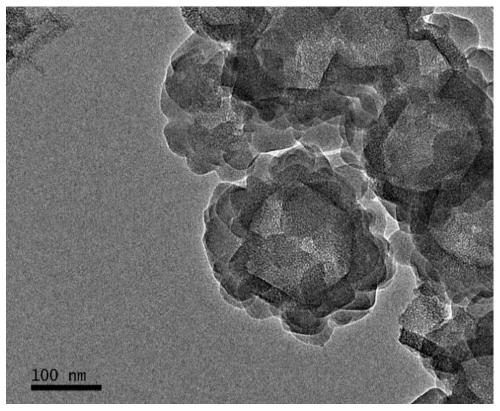

[0038] 2. Preparation of hollow mesoporous silica spherical core:

[0039] Prepare 400mL of a mixed solution of water and absolute ethanol, the volume ratio of water and absolute ethanol is 5:4, add 2-methylimidazole, and control the concentration of 2-methylimidazole to 62mM. The ZIF-8 nanoparticles obtained through the above steps were ultrasonically dispersed in a mixed solution composed of water, absolute ethanol and 2-methylimidazole for 3...

Embodiment 2

[0045] 1. Preparation of ZIF-8 self-sacrificing template:

[0046] Dissolve zinc nitrate hexahydrate in 100mL methanol to form solution A, the concentration of zinc nitrate is 50mM; weigh 2-methylimidazole and dissolve it in 100mL methanol to form solution B, the concentration of 2-methylimidazole is 0.75M. Pour solution B into solution A, and stir the mixed solution vigorously for 3 h at a stirring speed of 3000 rpm / min. Wash by centrifugation, wash with methanol three times, and dry overnight at 60° C. to obtain ZIF-8 nanoparticles.

[0047] 2. Preparation of hollow mesoporous silica spherical core:

[0048] Prepare 400mL of a mixed solution of water and absolute ethanol, the volume ratio of water and absolute ethanol is 5:4, add 2-methylimidazole, and control the concentration of 2-methylimidazole to 70mM. The ZIF-8 nanoparticles obtained through the above steps were ultrasonically dispersed in a mixed solution composed of water, absolute ethanol and 2-methylimidazole for...

Embodiment 3

[0054] 1. Preparation of ZIF-8 self-sacrificing template:

[0055] Dissolve zinc nitrate hexahydrate in 100mL methanol to form solution A, the concentration of zinc nitrate is 42mM; weigh 2-methylimidazole and dissolve it in 100mL methanol to form solution B, the concentration of 2-methylimidazole is 0.65M. Pour solution B into solution A, and stir the mixed solution vigorously for 3 h at a stirring speed of 3000 rpm / min. Wash by centrifugation, wash with methanol three times, and dry overnight at 60° C. to obtain ZIF-8 nanoparticles.

[0056] 2. Preparation of hollow mesoporous silica spherical core:

[0057] Prepare 600mL of a mixed solution of water and absolute ethanol, the volume ratio of water and absolute ethanol is 5:4, add 2-methylimidazole, and control the concentration of 2-methylimidazole to 62mM. The ZIF-8 nanoparticles obtained through the above steps were ultrasonically dispersed in a mixed solution composed of water, absolute ethanol and 2-methylimidazole for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com