Antibacterial and mildew-proof barrier coating

An antibacterial, antifungal, and coating technology, which is applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of high cost and difficult promotion, and achieve low cost, reduce environmental pollution and public nuisance, Density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An antibacterial and antifungal barrier coating, its raw materials include by weight percentage: 35% of water-based acrylic emulsion, 8% of nanocellulose, 2% of water-based wax paste, 7% of tourmaline, 5% of activated carbon, 3% of nano-silver powder, six 5% of cyclolith powder, the remaining proportion is 35% of water and alcohol, and the nanocellulose is a composition of microfibrillated cellulose, coniferous wood nanocellulose, cotton nanocellulose and seaweed nanocellulose.

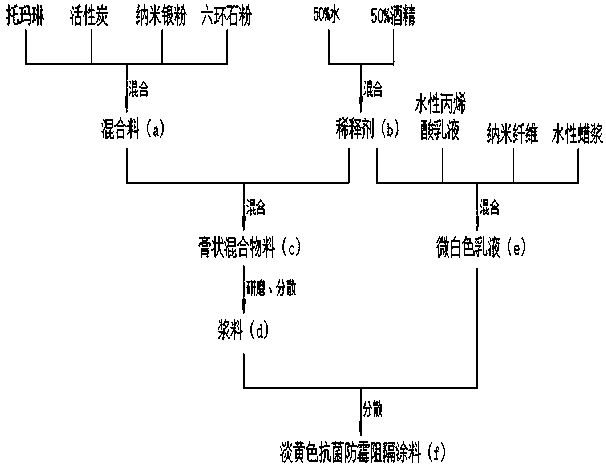

[0028] A preparation method of an antibacterial and antifungal barrier coating, specifically comprising the following steps:

[0029] S1. Put tourmaline, activated carbon, nano-silver powder and hexacyclic stone powder into the mixing equipment according to the proportion and mix them thoroughly to obtain the mixture (a). The working temperature of the mixing equipment is 50°C, and the working speed is 550r / min;

[0030] S2. Mix 50% water and 50% alcohol homogeneously as diluent (b);

[0031...

Embodiment 2

[0036] An antibacterial and antifungal barrier coating, its raw materials include by weight percentage: 34% of water-based acrylic emulsion, 7% of nanocellulose, 1% of water-based wax paste, 6% of tourmaline, 6% of activated carbon, 4% of nano-silver powder, six 6% of cyclolith powder, the remaining proportion is 36% of water and alcohol, and the nanocellulose is a composition of microfibrillated cellulose and softwood nanocellulose.

[0037] A preparation method of an antibacterial and antifungal barrier coating, specifically comprising the following steps:

[0038] S1. Add tourmaline, activated carbon, nano-silver powder and hexacyclic stone powder into the mixing equipment according to the proportion and mix them thoroughly to obtain the mixture (a). The working temperature of the mixing equipment is 45°C, and the working speed is 500r / min;

[0039] S2. Mix 50% water and 50% alcohol homogeneously as diluent (b);

[0040] S3. Add equal weight diluent (b) in step S2 to the...

Embodiment 3

[0045] An antibacterial and antifungal barrier coating, its raw materials include by weight percentage: 36% of water-based acrylic emulsion, 9% of nano-cellulose, 3% of water-based wax paste, 8% of tourmaline, 4% of activated carbon, 2% of nano-silver powder, six The cyclolith powder is 4%, the remaining proportion is 34% of water and alcohol, and the nanocellulose is a composition of cotton nanocellulose and seaweed nanocellulose.

[0046] A preparation method of an antibacterial and antifungal barrier coating, specifically comprising the following steps:

[0047] S1. Put tourmaline, activated carbon, nano-silver powder and hexacyclic stone powder into the mixing equipment according to the proportion and mix them thoroughly to obtain the mixture (a). The working temperature of the mixing equipment is 55°C, and the working speed is 600r / min;

[0048] S2. Mix 50% water and 50% alcohol homogeneously as diluent (b);

[0049] S3. Add equal weight diluent (b) in step S2 to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com