Porous preform, preparation method thereof, foam metal and preparation method thereof

A metal foam and prefabricated technology, applied in the field of metal foam, can solve the problems of poor opening degree, limited contact area, large flow resistance, etc., achieve the effect of simple production method and equipment, increase the size of the connecting hole, and improve the connecting structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

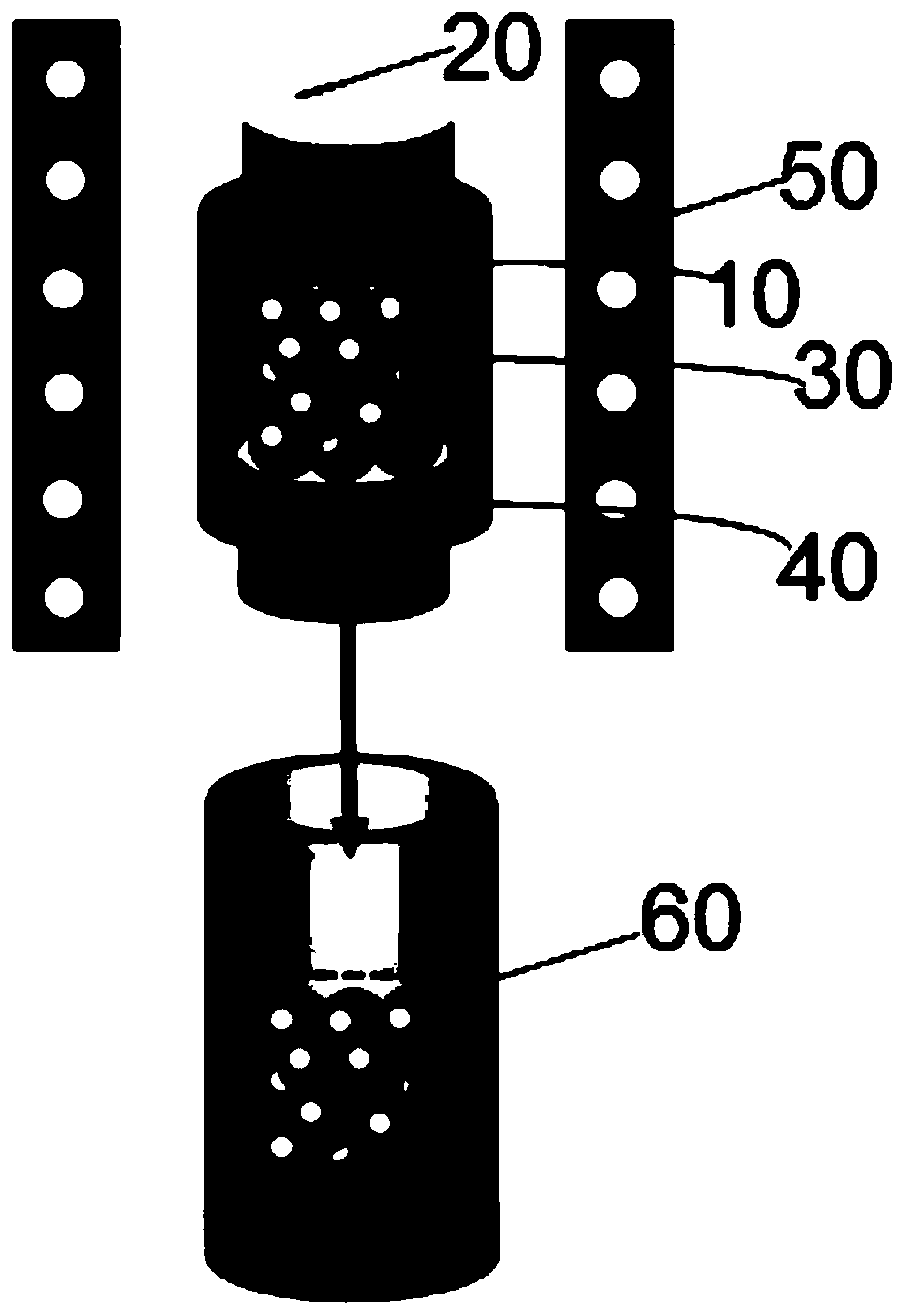

[0034] An embodiment of the present invention provides a method for preparing a porous preform, comprising the following steps:

[0035]S100, stacking the inorganic salt particles in a container with a closed bottom to form an accumulation of inorganic salt particles;

[0036] S200, using a compaction method to make the inorganic salt particle accumulation body have a preliminary compactness in the container;

[0037] S300, apply a downward constant pressure of 1 MPa to 10 MPa above the accumulation of inorganic salt particles, and raise the temperature of the container containing the accumulation of inorganic salt particles to 0.2Tm to 0.2Tm at a heating rate of 5°C to 20°C. 0.8Tm and heat preservation;

[0038] S400, keeping the temperature for 1 hour to 8 hours, causing the inorganic salt particles to creep and deform.

[0039] The preparation method of the porous prefabricated body in the embodiment of the present invention controls the pressure, temperature, and time. B...

Embodiment 1

[0067] Step 1, preparation of porous preform.

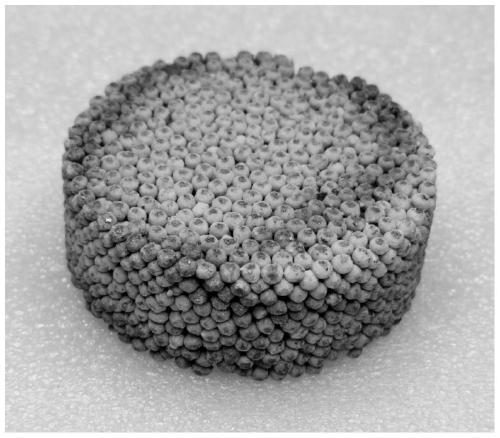

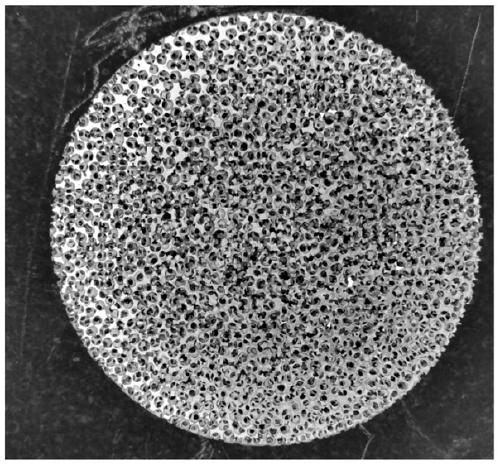

[0068] In this example, industrial pure aluminum is selected as the metal raw material, and CaCl 2 As inorganic salt particles. After particle sieving, CaCl 2 The particle diameter of the particles was 3.5 mm. see figure 1 , assemble the lower pressure head to the bottom of the hollow cylindrical cylinder as a container for standby, and put the sieved CaCl 2 The particles are piled into the container to form an accumulation of inorganic salt particles, and manual vibration and pressure compaction are used to make the inorganic salt particles have a preliminary degree of compaction. The quality of the upper pressure head is 5Kg, which is pressed on the upper surface of the inorganic salt particle accumulation body, and the CaCl 2 The particle container was placed in a heating furnace, and the heating furnace was heated to 550° C. at a heating rate of 10° C. and kept for 2 hours. Take out the container, and take out the porou...

Embodiment 2

[0075] Step 1, preparation of porous preform.

[0076] In this example, industrial pure tin is selected as the metal raw material, and KCl is selected as the inorganic salt particles. After particle sieving, the particle size of the KCl particles was 2.5 mm. Assemble the lower pressure head to the bottom of the hollow cylindrical cylinder as a container for standby, accumulate the sieved KCl particles into the container to form an accumulation of inorganic salt particles, and use manual vibration and pressure compaction to make the inorganic salt particles have a preliminary tightness. Solidity. The mass of the upper pressure head is 10Kg, which is pressed on the upper surface of the inorganic salt particle accumulation body, the container containing the KCl particles is placed in the heating furnace, and the heating furnace is heated to 500°C at a heating rate of 15°C and kept for 1h. Take out the container, and take out the porous prefabricated body after cooling for later...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com