High-elastic yarn preparation method and shell fabric manufactured using same

A technology for stretching yarn and fabrics, applied in yarn, dyeing, textiles and papermaking, etc. It can solve the problems of high bulkiness and insufficient elasticity, and achieve the effect of good anti-pilling and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, network processing. The network fastness is required to be high, and the tightness is moderate and uniform. The key component of the network is the network device. In this case, the improved closed single-hole network device is used for the network screening. The installation position of the added network nozzle is consistent with the running direction of the yarn. In order to make the yarn enter the nozzle yarn path smoothly and not be easy to blow out, the nozzle must have a certain directionality, and it is usually installed at an inclination angle. In this example, the process parameters used for network processing are: air pressure 0.35Mpa, running speed of network wire is 220m / min.

[0024] Step 2, texturing. Texturing is actually a heat treatment for shaping. By adjusting and selecting the shaping tension (ie: positive overfeed, negative overfeed), setting temperature, and processing time, the elasticity of the network yarn is adjusted. In this embodim...

Embodiment 2

[0033] (1) Network processing. The process parameters are: air pressure 0.3Mpa, processing speed 200m / min.

[0034] (2) Textile processing. Temperature: 210°C, time: 60s, overfeed tension control: 5CN.

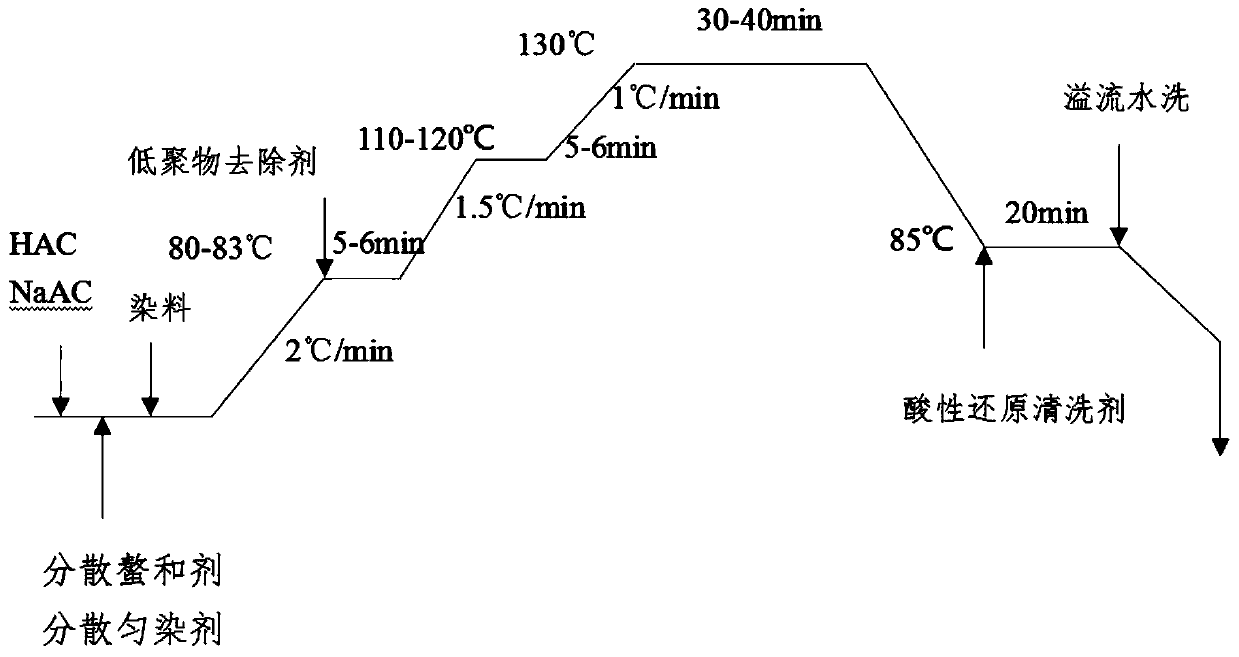

[0035] (3) Dyeing. High temperature and high pressure skein dyed black. Specifically, the dyeing process adopts a gradient constant temperature process, and the dyeing bath is prepared at room temperature. The dyeing bath is mixed with water, HAC, NaAC, dispersing chelating agent, dispersing leveling agent, and dyes. Polymer remover and keep the temperature constant for 5min, the heating rate is 2°C / min, then raise the temperature to 120°C and keep the temperature for 10min, the heating rate is 1.5°C / min, then raise the temperature to 130°C and keep the temperature for 35min, the heating rate is 1°C / min, and finally cool down To 85 ℃ and add acid reduction cleaning agent, constant temperature for 20min and overflow water washing.

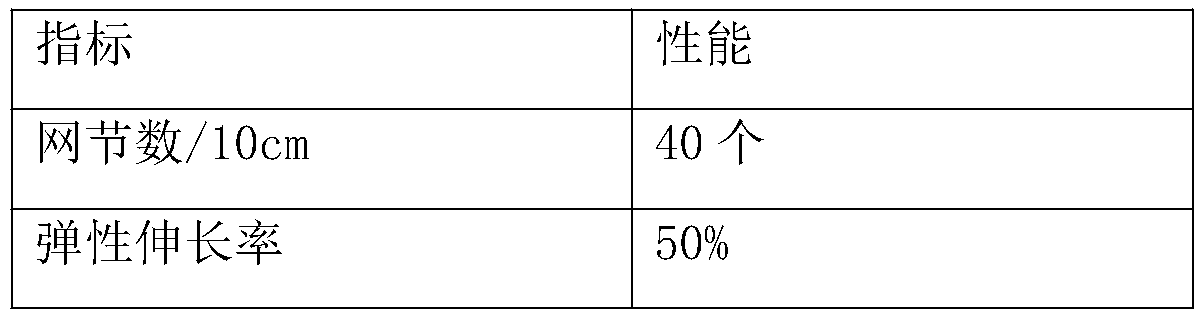

[0036] Step 4, wherein the initial netwo...

Embodiment 3

[0042] (1) Network processing. The process parameters are: air pressure 0.25Mpa, processing speed 180m / min.

[0043] (2) Textile processing. Temperature: 230°C, time: 100s, overfeed tension control: 12CN.

[0044] (3) Dyeing. High temperature and high pressure skein dyed blue. Specifically, the dyeing process adopts a gradient constant temperature process,

[0045] Prepare the dyeing bath solution at room temperature. The dyeing bath solution is to mix water, HAC, NaAC, dispersing chelating agent, dispersing leveling agent, and dyes and raise the temperature to 85°C, add oligomer remover and keep the temperature constant for 6 minutes. The heating rate is 2°C / min, then raise the temperature to 20°C and keep the temperature for 6 minutes, the heating rate is 1.5°C / min, then raise the temperature to 130°C and keep the temperature for 30 minutes, the heating rate is 1°C / min, finally cool down to 85°C and add acid reduction cleaning agent, keep the temperature 20min and wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com