Energy-saving and environment-friendly fabricated wall and assembly method thereof

An energy-saving, environment-friendly, prefabricated technology, applied to walls, thermal insulation, building insulation materials, etc., can solve problems such as unlocated devices, installation failures, and increased construction costs, to achieve reduced area and weight, convenient bolt connections, and prevent misalignment The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

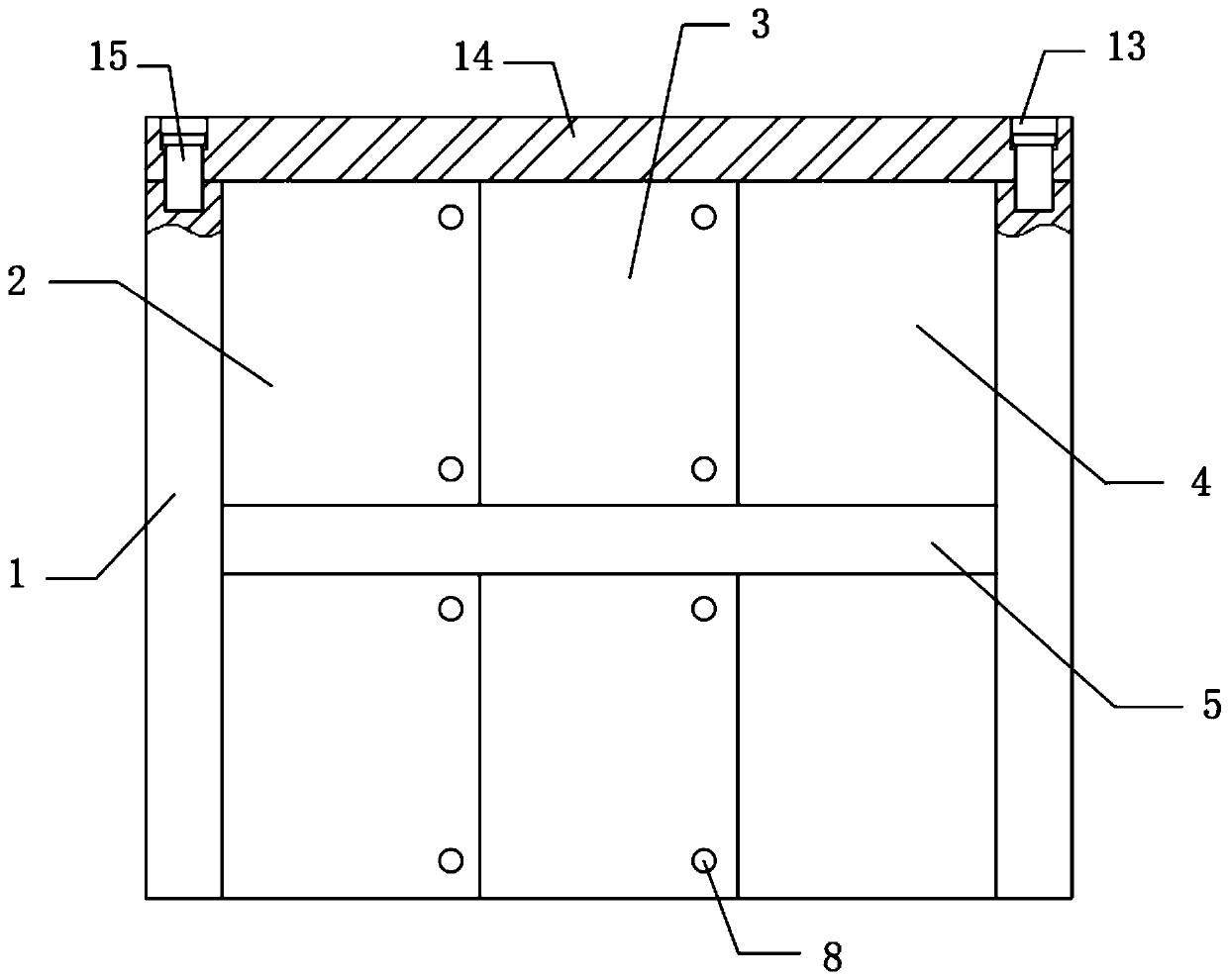

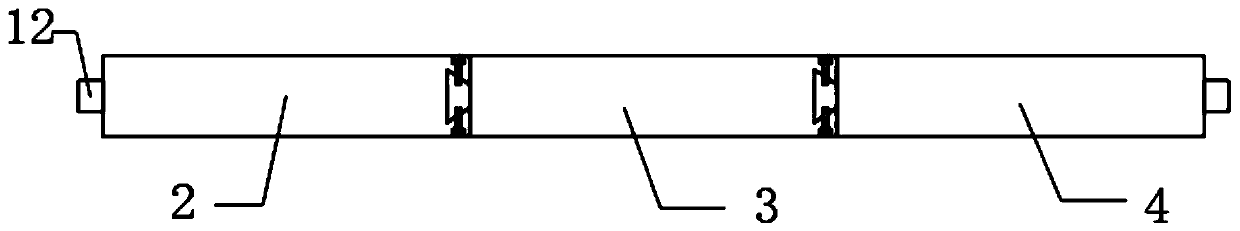

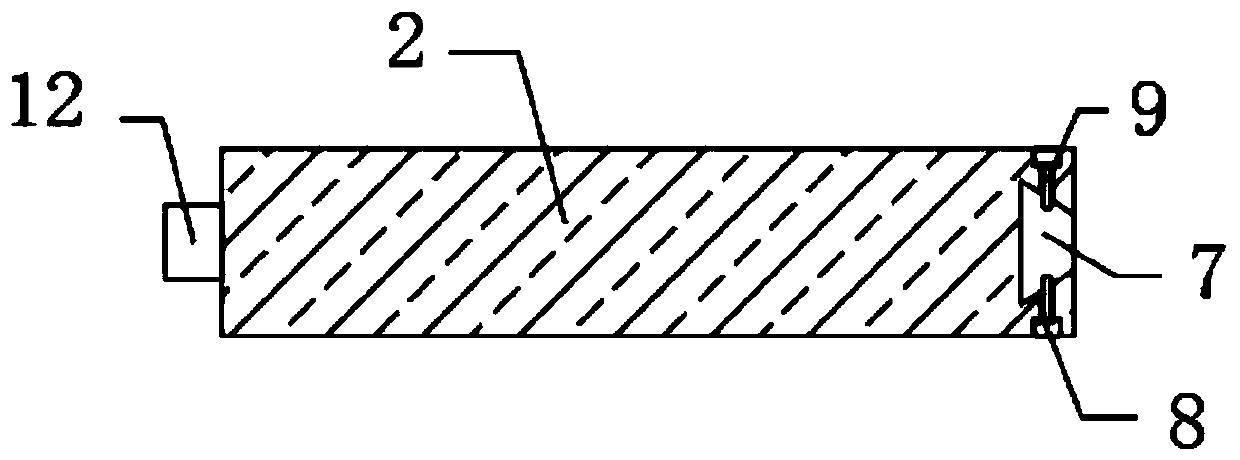

[0049] see Figure 1-8 , an energy-saving and environment-friendly fabricated wall, including two pillars 1, please refer to figure 1 and Figure 8 , a beam plate 14 is arranged between the upper ends of the pillars 1, the upper side walls of both ends of the beam plate 14 are provided with second installation holes 13, and self-tapping bolts 15 are threaded in the second installation holes 13, and the two pillars 1 The upper end side walls of the beam plate 14 are provided with threaded holes matching the self-tapping bolts 15, and the beam plate 14 connects the top of the two pillars 1 to play a role of strengthening and stability. The lower end side wall of the beam plate 14 is provided with a limiting groove 21 And the width of the limiting groove 21 is slightly larger than the width of the first wall body 2, the second body of wall body 3 and the third body of wall body 4, and the top of the body of first wall body 2, the body of wall body 3 and the third body of wall bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com