Diamond saw blade rotary sintering furnace and rotary sintering process

A technology of diamond saw blade and rotary sintering furnace, applied in the direction of rotary drum furnace, furnace, furnace components, etc., can solve the problems of short distance between saw blade column and shielding cylinder, large difference in average temperature, difference in sintering temperature, etc. Transfer efficiency, improve heating efficiency, and the effect of small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

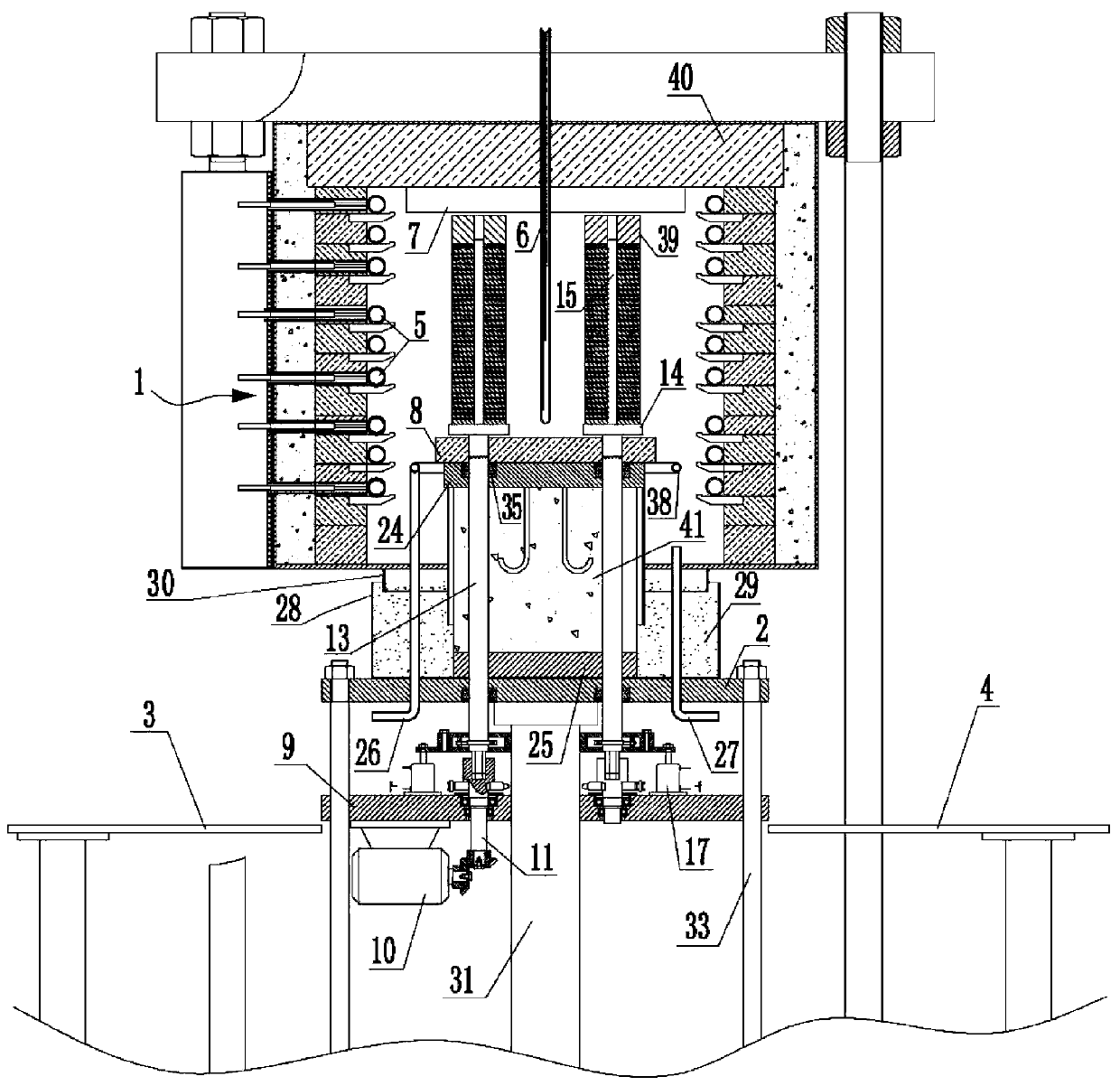

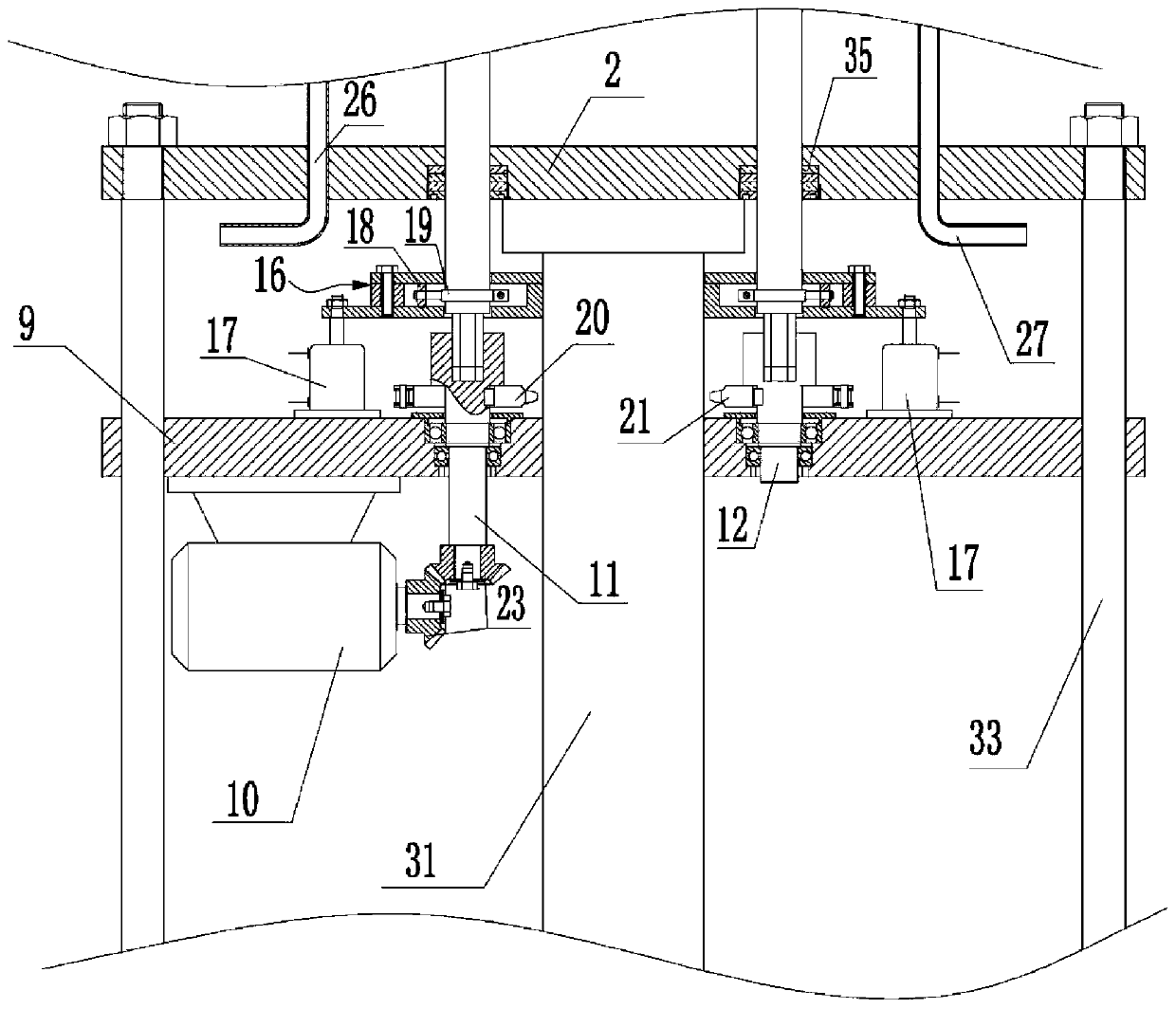

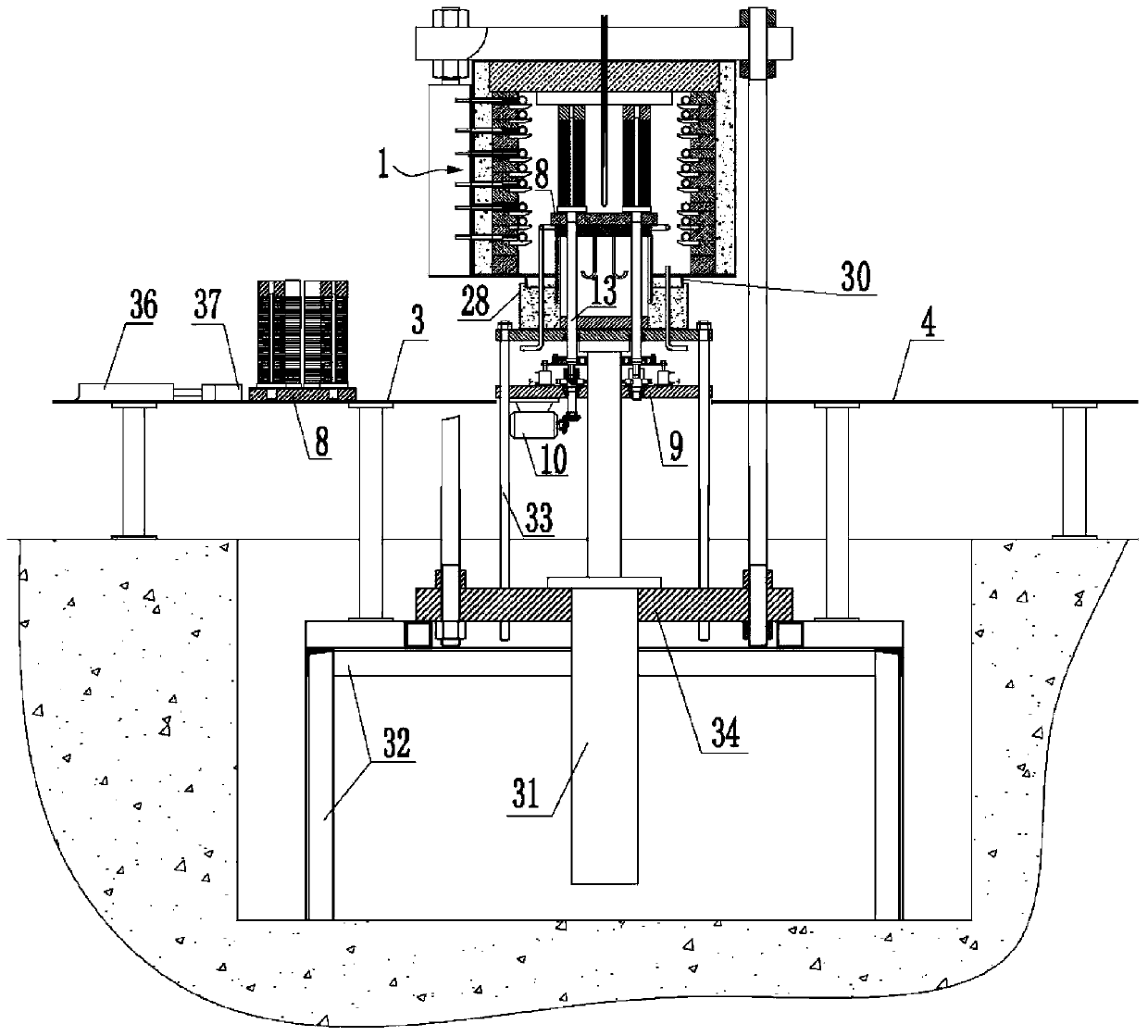

[0043] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0044] The present invention is a rotary sintering furnace for diamond saw blades. The existing sintering furnace is improved to have a rotating assembly, which can keep the saw blades in a rotating state when processing the diamond saw blades. At the same time, the processing technology of diamond saw blade is also improved for rotary sintering furnace. Diamond saw blade rotary sintering furnace includes two forms of heating furnace and cooling furnace according to needs. The structures of heating furnace and cooling furnace are roughly similar. The only difference is that the heating furnace is a heating system and the cooling furnace is a cooling system. When processing a diamond saw blade, it is first heated and pressurized in a heating furnace, and then transferred to a cooling furnace for cooling. The structure of the diamond saw blade ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com