Mechanical property detection and data processing method for hydrate-containing sediments

A technology containing hydrates and data processing, applied in the direction of strength characteristics, using a stable shear force to test the strength of materials, measuring devices, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for detecting mechanical properties and data processing of hydrate-containing sediments, the specific steps are as follows:

[0063] 1. Install the sample to be tested and impose a simulated environment;

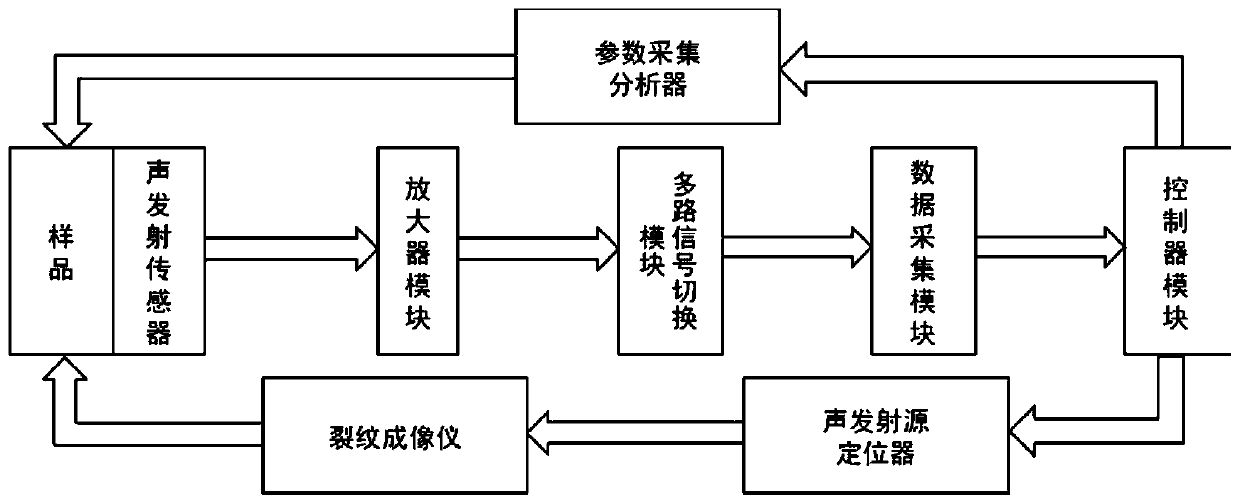

[0064] 2. Adjust the three-axis loading acoustic emission signal detection device to perform zero point calibration;

[0065] 3. On the control host, set the amplifier gain, the logic sequence of the switch on and off in the multi-channel signal switching module, and configure the parameters of the data acquisition module. The parameters include sampling mode, sampling frequency, sampling amplitude range, and sampling channel; open parameter acquisition analyzers, acoustic emission source locators and crack imagers;

[0066] 4. For the static detection process, start the motor when the sample to be tested is in a stable state, apply axial stress to shear the sample, and control the shearing rate of the sample by controlling the magnitude of the axial stress;...

Embodiment 2

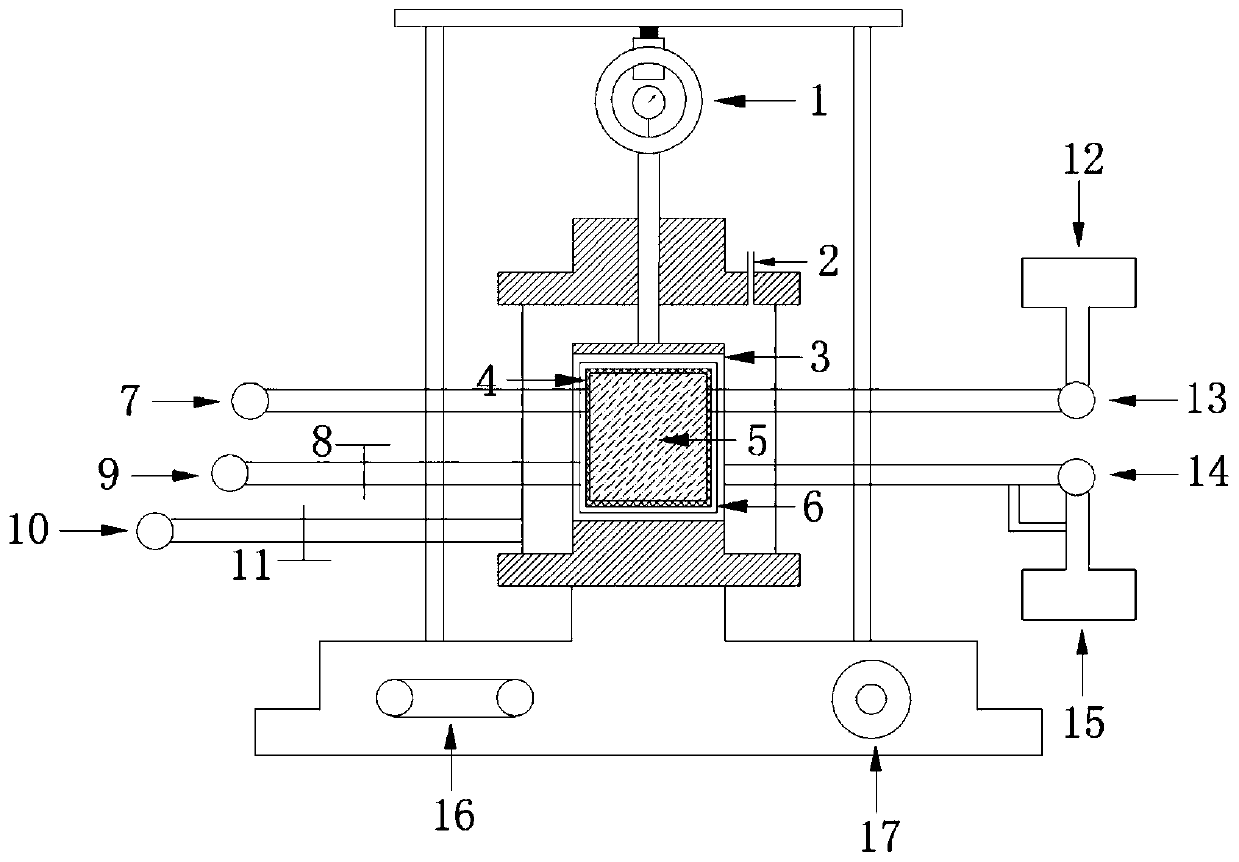

[0074] Triaxial loading acoustic emission signal detection device. The triaxial pressure chamber is an important part of the triaxial loading device. It is composed of an upper metal cover, plexiglass and a base, and is a cylindrical space. The surrounding pressure system is used to control the pressure in the pressure chamber. The confining pressure system includes a pressure pump, a pressure display instrument and a regulating valve. By adjusting the relationship between the pressure in the pressure chamber and the external pressure, the pressure in the pressure chamber can be automatically compensated and stabilized. . The gear box is driven by a motor, and the pressure chamber can move from bottom to top through the transmission system to withstand axial pressure. At this time, the principal stress of the sample in the pressure chamber in the three directions cannot maintain balance, and the sample will be under the shear force. The axial stress can be controlled separatel...

Embodiment 3

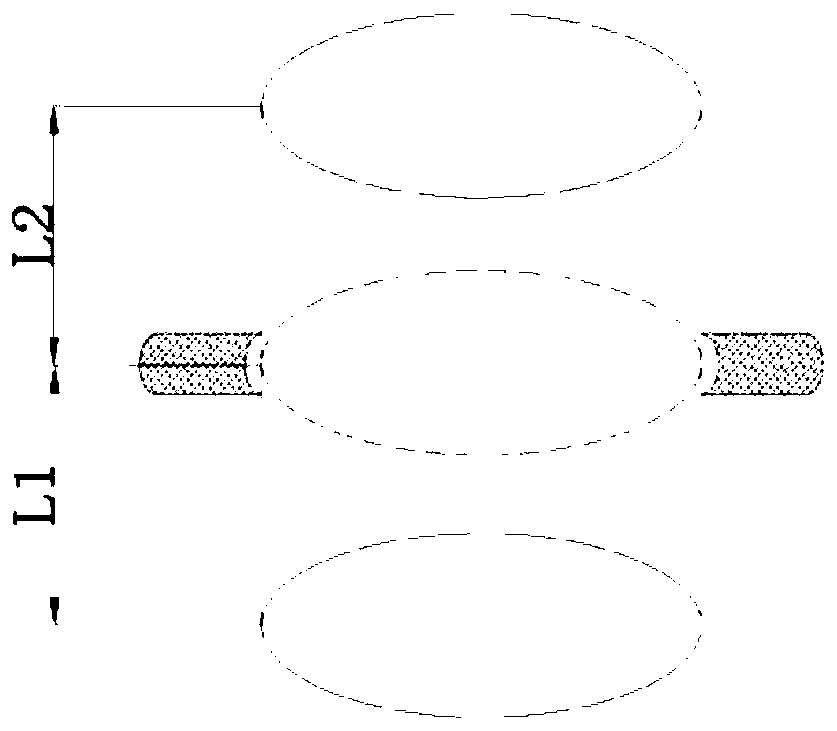

[0077] Refer to attached Figure 3-7 The installation method of the designed sensor, the installation method of the acoustic emission sensor includes two aspects: the number of sensors and the installation location.

[0078] 1) When using 2 acoustic emission sensors, install the sensors on the inner metal wall surface of the sample holder (the end surface of the sensor is flush with the inner wall), and fix it with a magnetic adsorption fixture, which is divided into two ways: facing and non-facing. The axial position can be changed;

[0079] 2) When 4 acoustic emission sensors are used, they are divided into two pairs and fixedly installed on the inner metal wall surface of the sample holder (the end surface of the sensor is flush with the inner wall), and the upper sensor on the axial direction and the upper end surface of the cylindrical sample There needs to be a certain distance between the middle and lower layer sensors and the lower end surface of the cylindrical sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com