Touch screen

A touch screen and polarizer technology, applied in optics, instruments, electrical and digital data processing, etc., can solve problems affecting electrostatic discharge, glue breakage, glue fineness, etc., to improve electrostatic discharge capacity, reduce process difficulty, and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

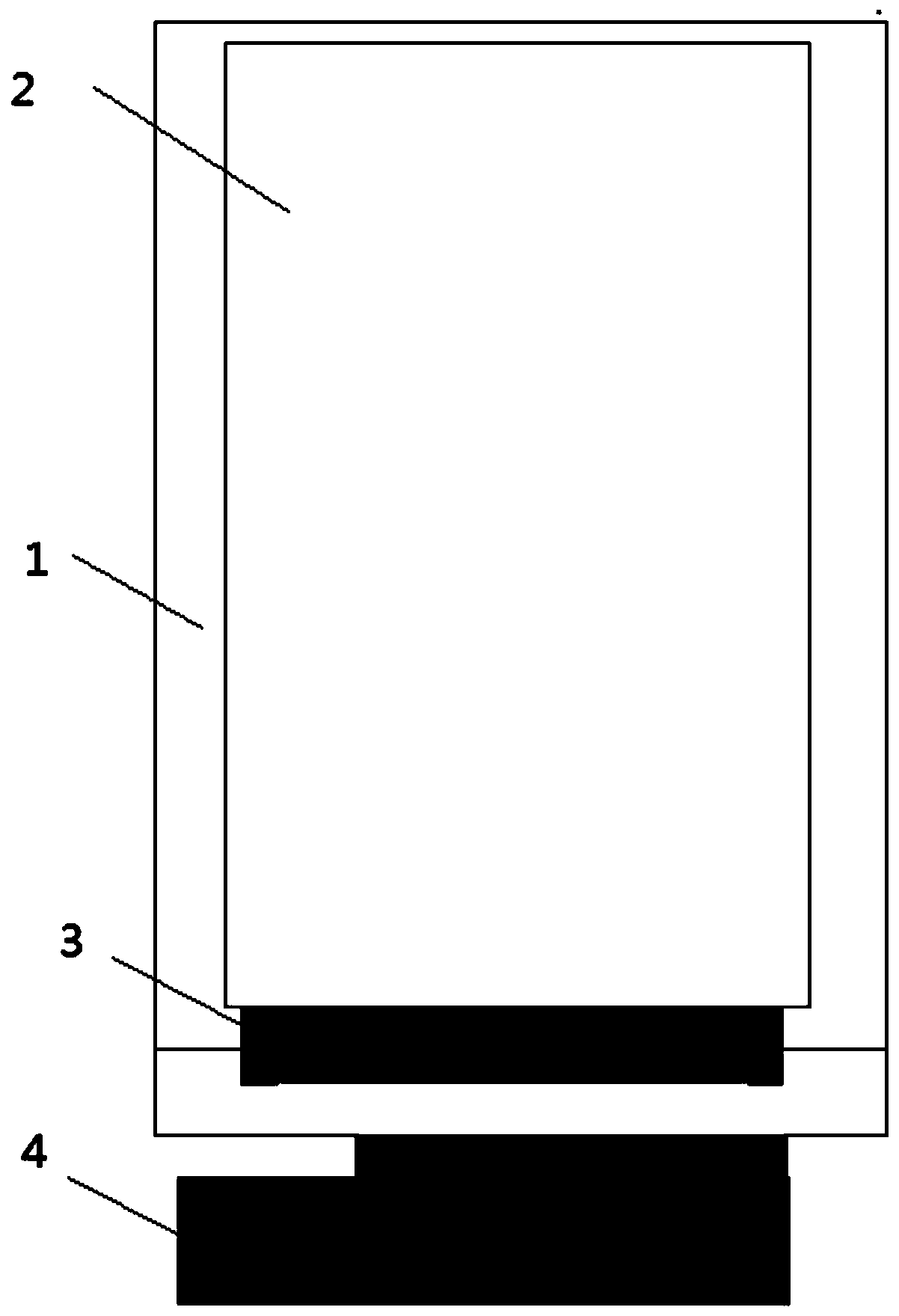

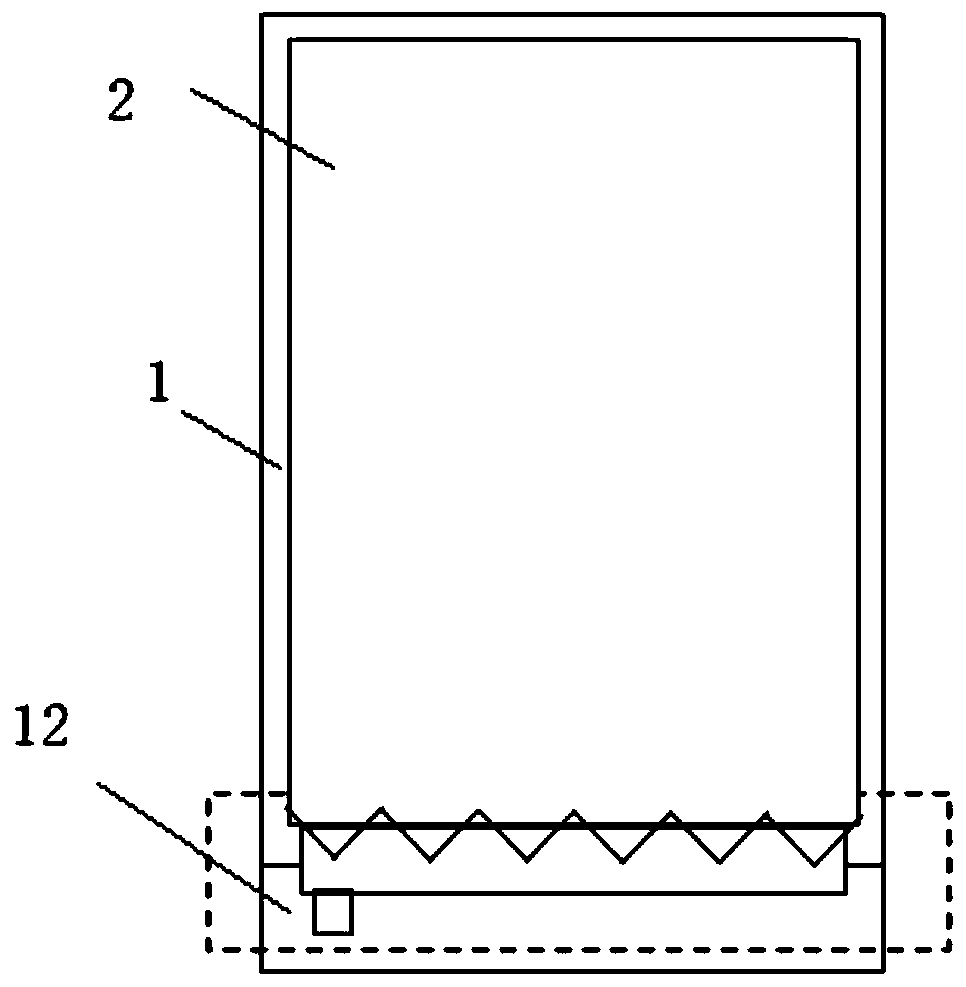

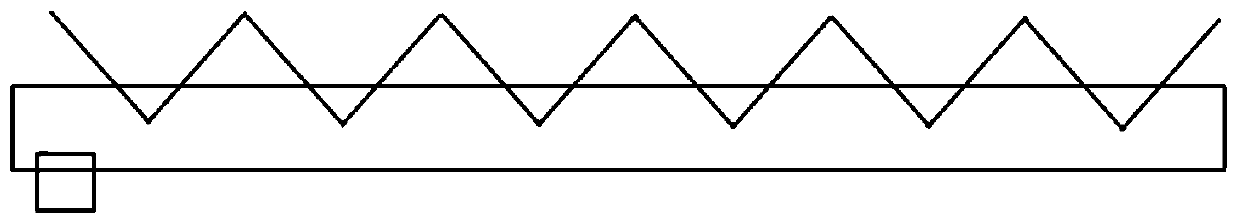

[0032] Such as Figures 2a to 2b As shown, change the cutting shape of the edge of the polarizer in contact with the silver paste, and change the shape and outline of the lower edge of the polarizer from a vertically cut straight line to a vertically cut folded line, as shown in Figure 2a with 2b shown. Depend on Figure 2b It can be seen that the present invention increases the contact area between the silver paste and the cross-section pressure-sensitive adhesive of the polarizer, and improves the electrostatic discharge capacity. Compared with the prior art, greater silver paste coating deviation (position deviation, glue width deviation) can be allowed. Specifically, for the conventional method, the coating tolerance for better contact of the edge polarizer edge on the silver paste coating is very limited; for the present invention, from Figure 2b It can be seen that the coating tolerance can be effectively increased.

Embodiment 2

[0034] Such as Figures 3a to 3c As shown, changing the cutting shape of the edge of the polarizer in contact with the silver paste, and changing the shape of the lower edge of the polarizer from a vertically cut straight line to a vertically cut square wave, trapezoidal, and wavy shape can also achieve increased The contact area between the silver paste and the pressure-sensitive adhesive on the cross-section of the polarizer can improve the effect of electrostatic discharge ability; at the same time, it can also allow greater silver paste coating deviation (position deviation, glue width deviation).

Embodiment 3

[0036] Such as Figures 3a to 3b As shown, change the cutting method of the edge of the polarizer in contact with the silver paste, and change the shape and outline of the lower edge of the polarizer from a vertically cut straight line to a non-perpendicular cut (inclined at a certain angle, 0-90°) straight line, Figure 3a The shape profile of the lower edge of the polarizer shown is a straight line cut vertically, Figure 3b The shape profile of the lower edge of the polarizer shown is a straight line cut non-perpendicularly (inclined at a certain angle, 0-90°), which can also increase the contact area between the silver paste and the pressure-sensitive adhesive on the cross-section of the polarizer, and improve the electrostatic discharge. The effect of ability, at the same time, can also allow greater silver paste coating deviation (position deviation, glue width deviation).

[0037] Preferably, improvements are made on the basis of the above scheme to obtain a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com