Two-component developer for electrostatic charge image development

A two-component developer, electrostatic image development technology, applied in the direction of developer, electrography, instruments, etc., can solve the problem of unfavorable carrier consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0164] As binder resins used in the preparation of masterbatches or kneading with masterbatches, in addition to the above-mentioned modified and unmodified polyester resins, polystyrene, polyparachlorostyrene, and polyvinyltoluene can be cited. Polymers such as styrene and its substitutes; styrene-p-chlorostyrene copolymer, styrene-propylene copolymer, styrene-vinyltoluene copolymer, styrene-vinylnaphthalene copolymer, styrene-acrylic acid Methyl ester copolymer, styrene-ethyl acrylate copolymer, styrene-butyl acrylate copolymer, styrene-octyl acrylate copolymer, styrene-methyl methacrylate copolymer, styrene-ethyl methacrylate Copolymer, styrene-butyl methacrylate copolymer, styrene-α-chloromethyl methacrylate copolymer, styrene-acrylonitrile copolymer, styrene-vinyl methyl ketone copolymer, styrene- Styrene polymers such as butadiene copolymer, styrene-isoprene copolymer, styrene-acrylonitrile-indene copolymer, styrene-maleic acid copolymer, styrene maleate copolymer, etc. ...

Embodiment 1

[0465]

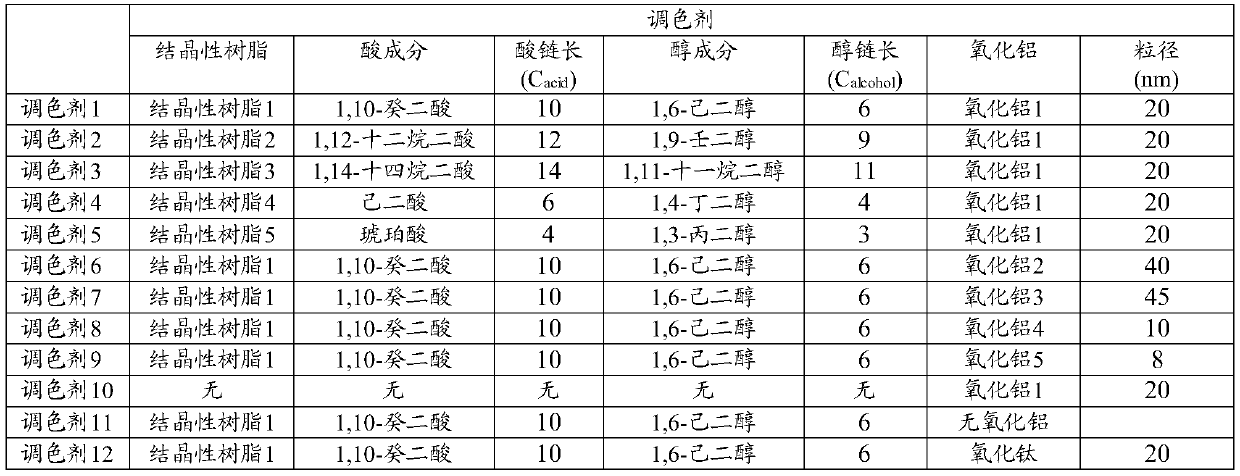

[0466] 1.0 kg of the carrier 1 prepared as described above was weighed, fed into a micro V-shaped mixer (manufactured by Tsutsui Rika Instrument Co., Ltd.), and the toner 1 was added so that the toner concentration was 7.5% by mass, Mixing was performed at 45 rpm for 30 minutes to prepare a two-component developer 1 .

Embodiment 2~16 and comparative example 1~4

[0467]

[0468] Two-component developers 2 to 20 were prepared in the same manner as in preparation of two-component developer 1 except that the combination of the carrier and the toner was changed to the combinations shown in Table 3 below.

[0469] "comment content"

[0470] [Evaluation 1: Minimum fixing temperature]

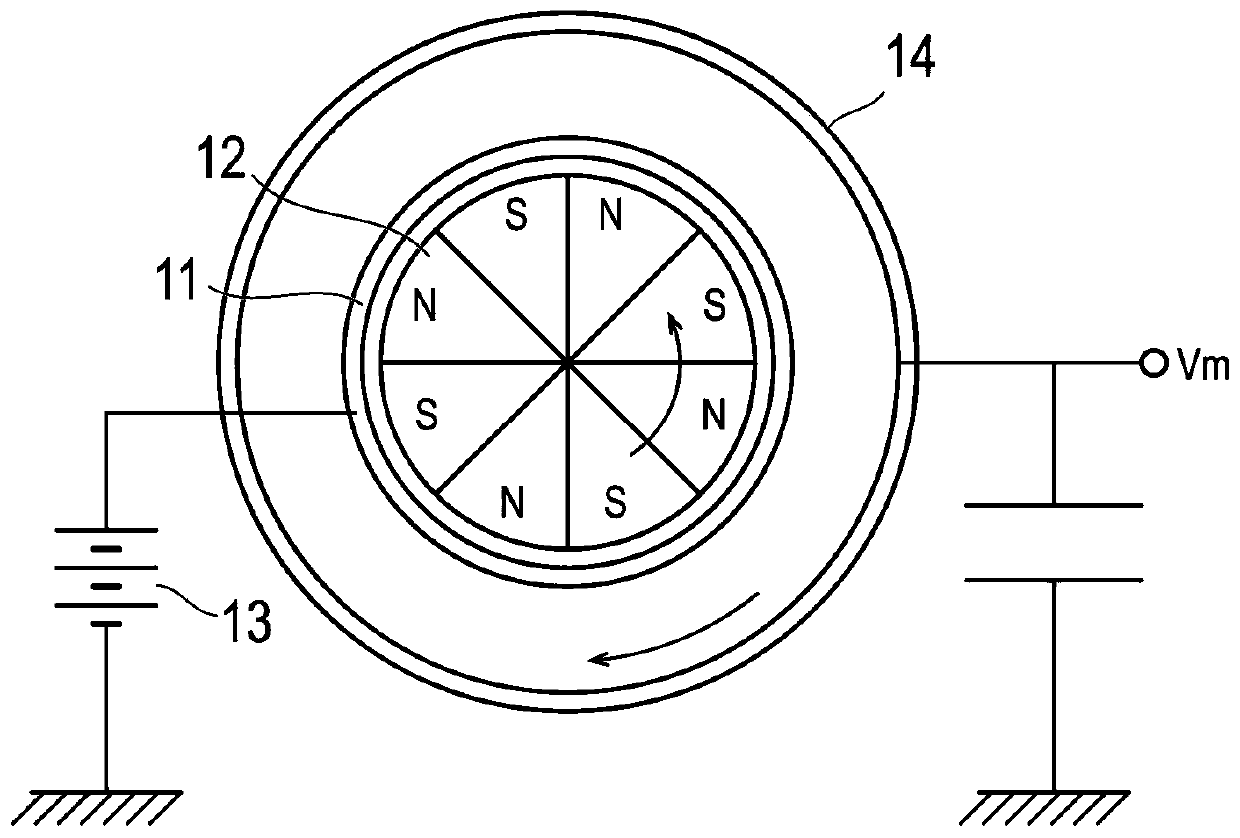

[0471] In the digital printer "bizhub PRES (registered trademark) C1070" (manufactured by Konica Minolta Corporation), the fixing device is modified so that the pressure and process speed (kneading time) of the kneading zone can be changed, and the fixing heating The surface temperature of the roll is modified so that it can be varied within the range of 100-210°C. The printing machine is equipped with two-component developers 1-20 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com