Temperature sensor and manufacturing method for same

A temperature sensor and sensor technology, applied in the direction of thermometers, resistors with negative temperature coefficients, thermometer parts, etc., to achieve the effect of improved adhesion and good temperature detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

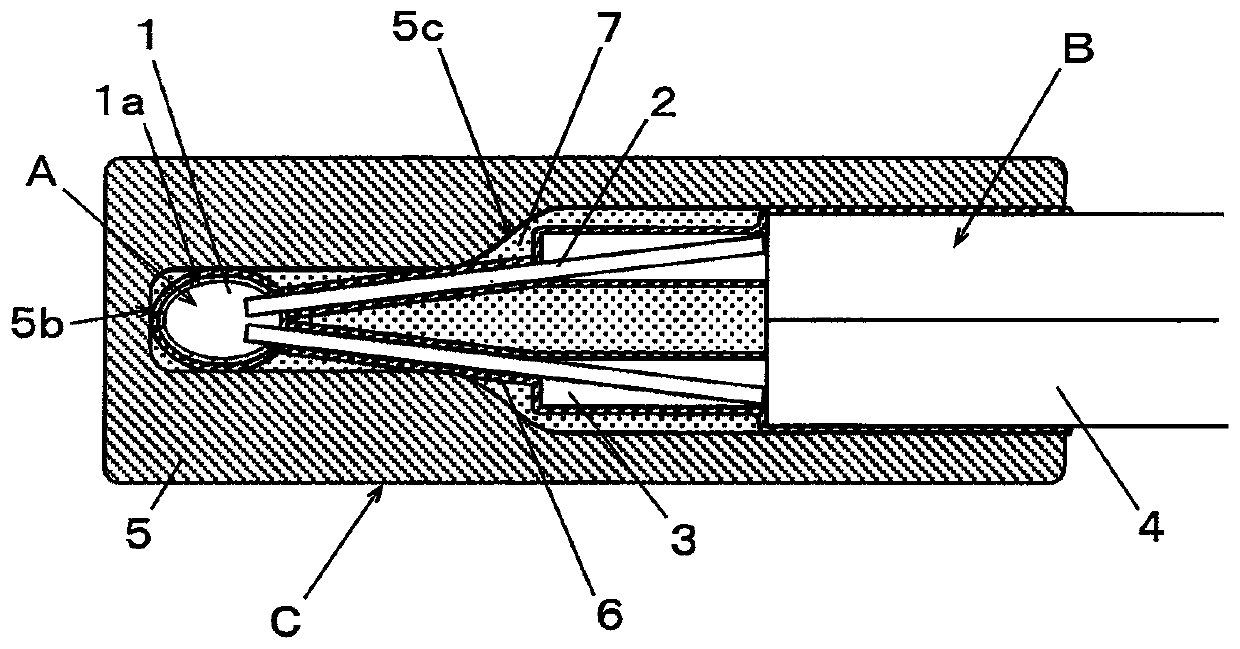

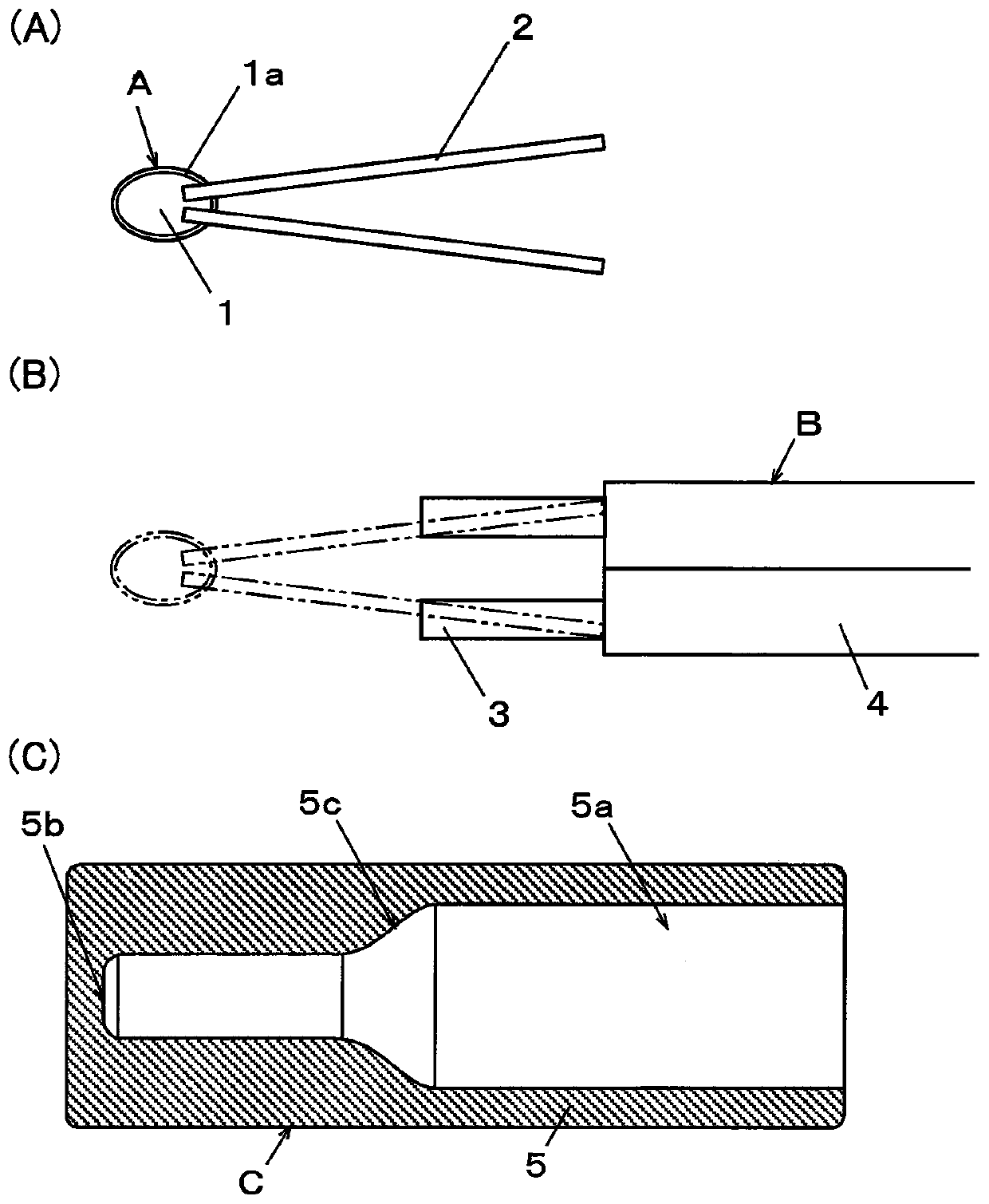

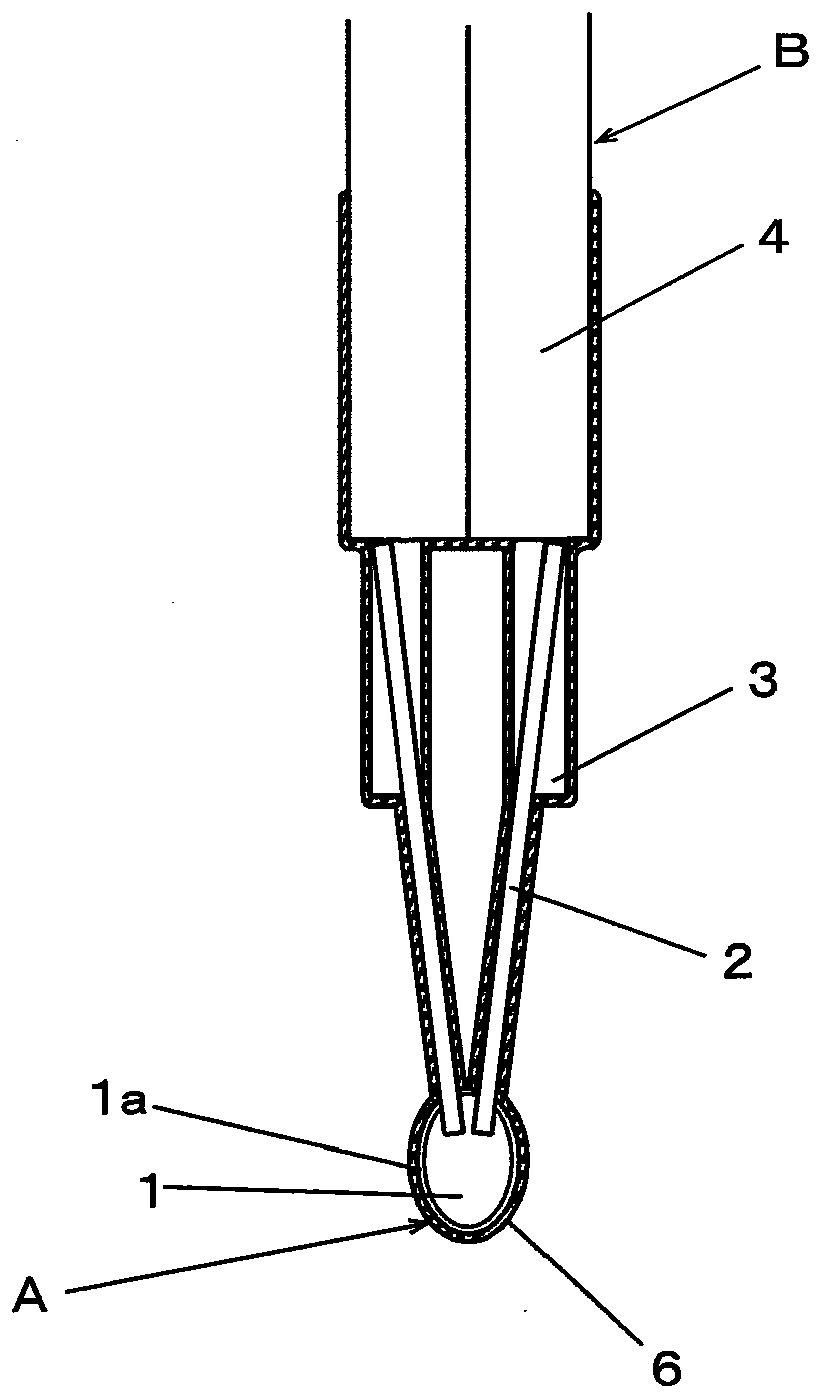

[0034] Hereinafter, embodiments of the temperature sensor of the present invention and a manufacturing method thereof will be described in detail based on the drawings.

[0035] The temperature sensor of the present invention is provided with: sensor part A, is made up of thermistor element 1 and connecting terminal 2; Configuration; and the covering part C covering the entirety of the sensor part A and the front end part of the cable part B.

[0036] The sensor unit A includes a glass-sealed thermistor element 1 whose surface is covered with a protective film 1a made of glass, and a pair of connection terminals 2, 2 for conducting electricity between the thermistor element 1 and a temperature control circuit.

[0037] The cable part B includes a pair of conductive wires 3, 3 and a sheath 4 made of fluororubber or the like covering the side surfaces thereof, and the pair of conductive wires 3, 3 are soldered to the pair of connection terminals 2, 2, respectively.

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com