Foot patch powder grinding device for foot patch production and method

A grinding device and foot patch technology, which is applied in chemical instruments and methods, packaging, transportation and packaging, etc., can solve the problems of hardening and solidification, high energy consumption, and affecting the use effect of foot patches, so as to improve stability and material distribution Uniform, waste-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

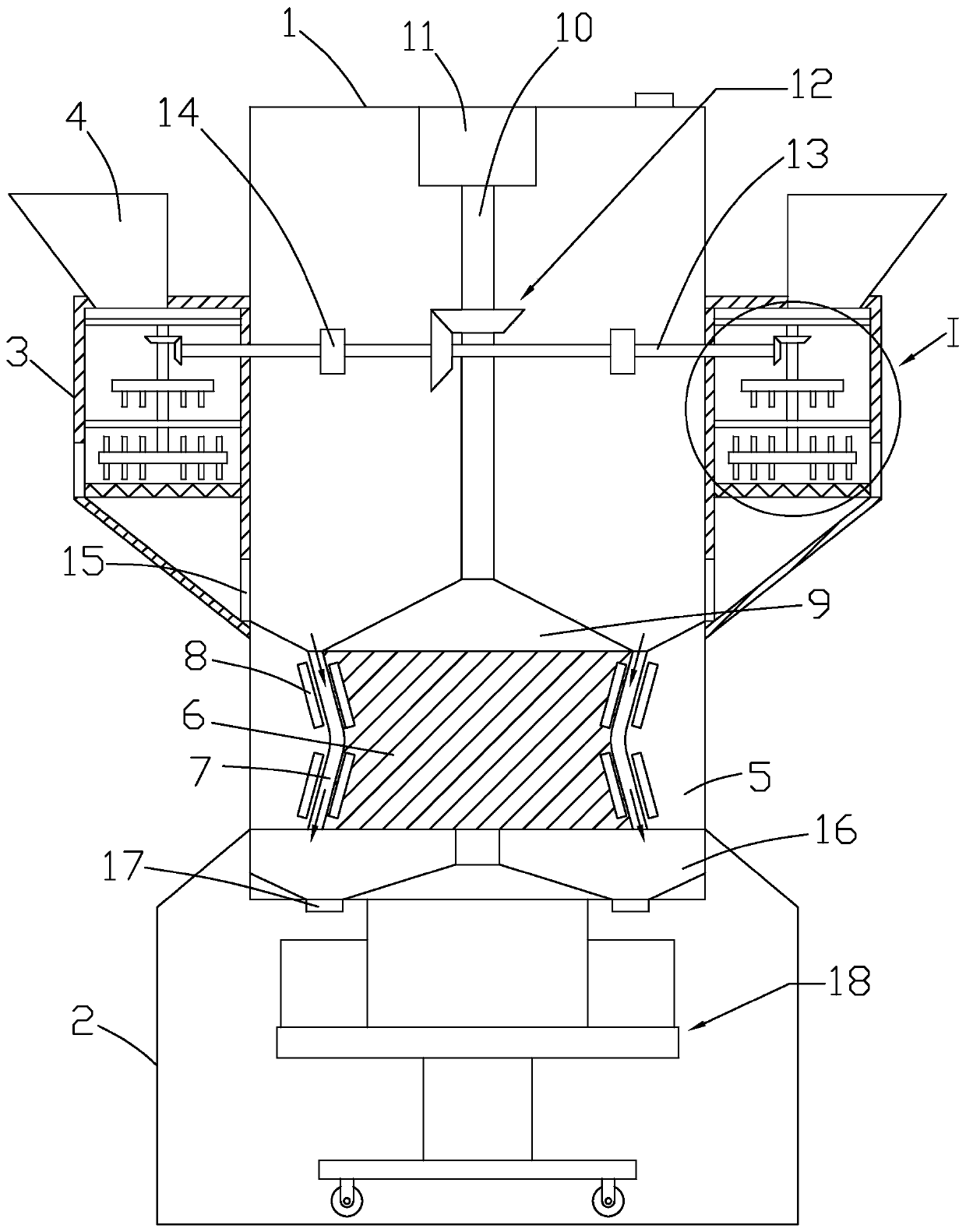

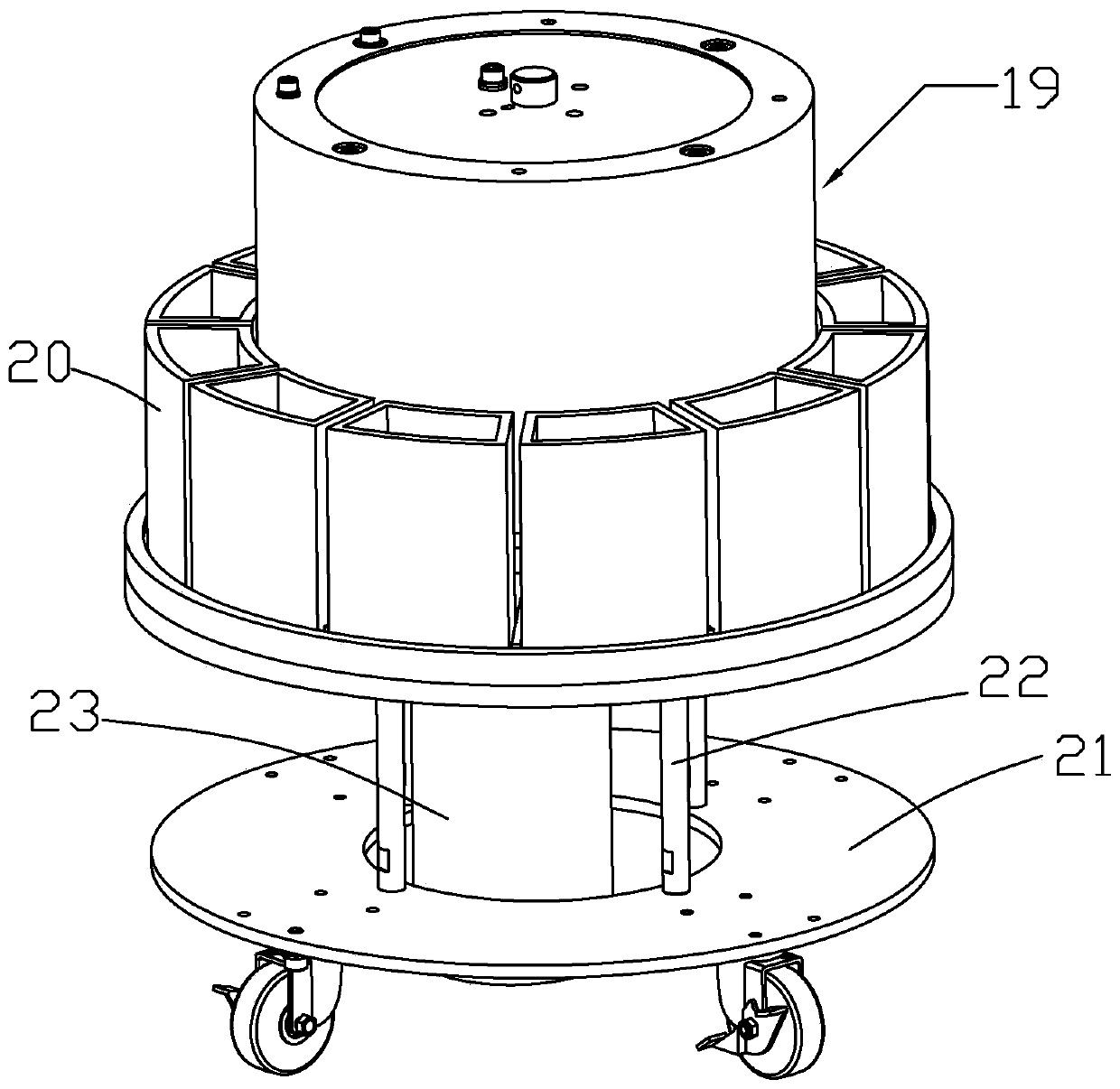

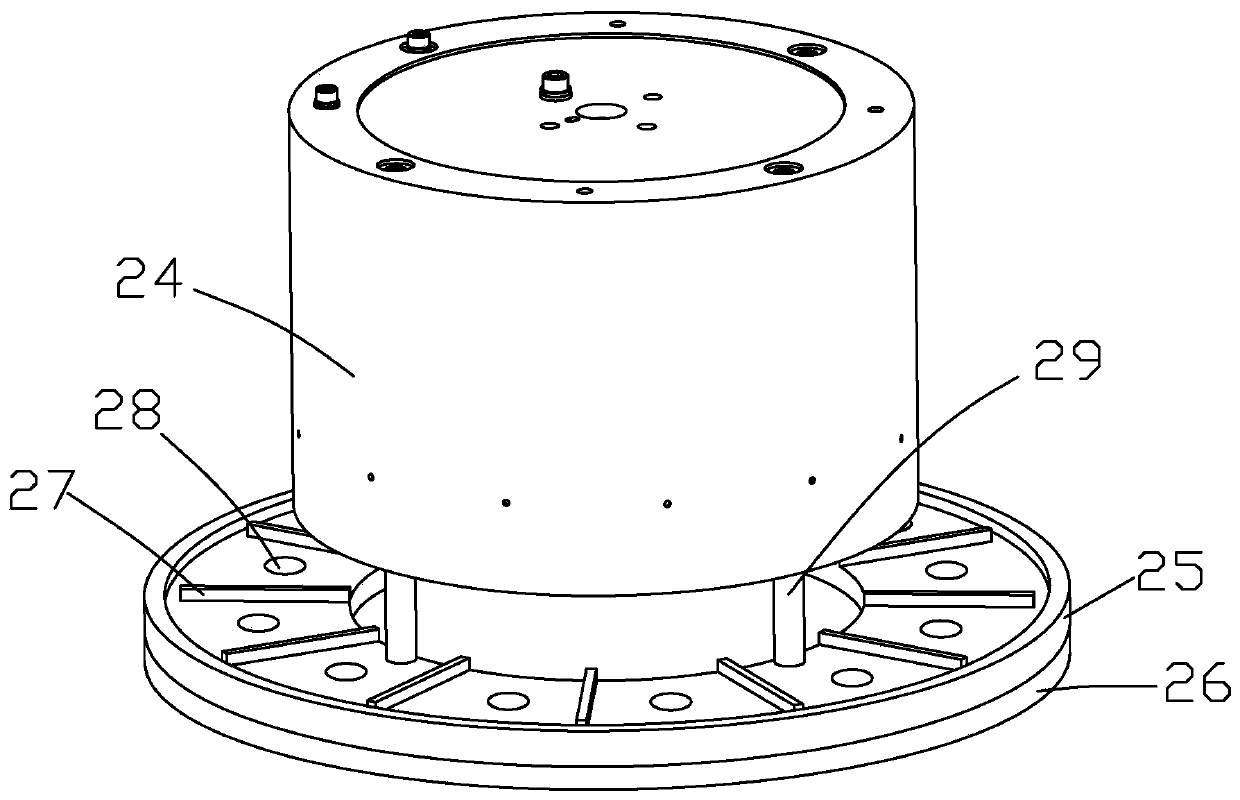

[0049] like Figure 1 to Figure 5 As shown, it is a foot patch powder grinding device for foot patch production according to the present invention, including a first box body 1 and a second box body 2, a grinding table 5 is arranged in the first box body 1, and a grinding table 5 is arranged at the center There is a grinding disc 6, the top of the grinding disc 6 is connected with the first rotating shaft 10 through the conical block 9, the top of the first rotating shaft 10 is connected with the first motor 11, and a grinding groove 7 is formed between the grinding disc 6 and the grinding table 5, and the grinding The groove 7 is arc-shaped, and the grinding disc 6 and the grinding table 5 are provided with a heating block 8 on the side close to the grinding tank 7, and the foot paste powder after filtering and separating enters the grinding tank 7, and passes through the joint of the grinding disc 6 and the grinding table 5. The function realizes grinding and crushing. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com